UV transfer printing in-mold-transfer printing decoration method

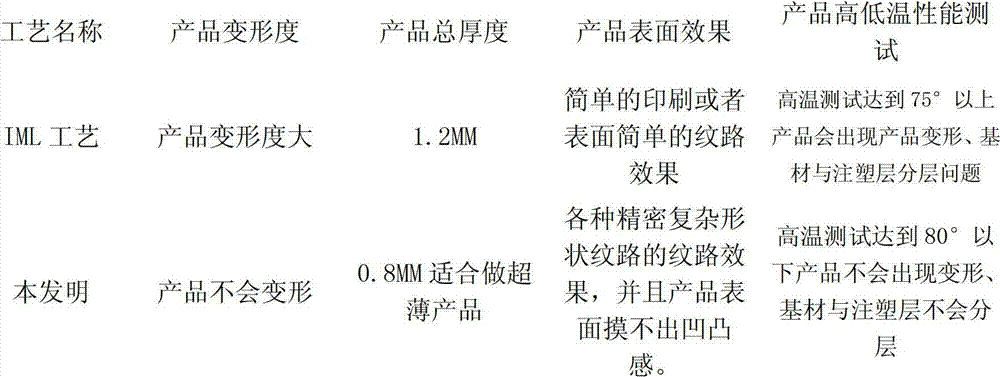

A technology of transferring molds and molds, applied in the direction of coating, etc., can solve problems such as failure to meet high and low temperature limit tests, product deformation, and easy flushing of ink at the injection molding inlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

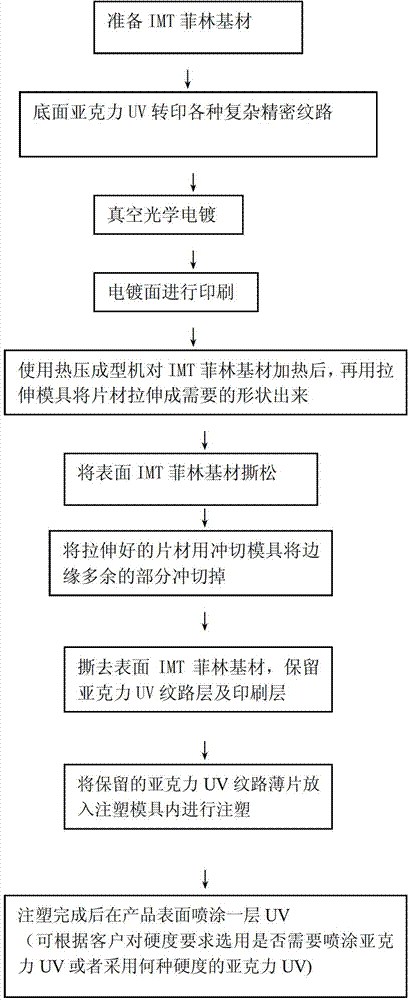

[0036] A UV transfer printing in-mold transfer decoration method is characterized in that it comprises the following steps:

[0037] (1) Prepare the IMT film, and make acrylic UV texture molding on the other side of the non-PET diaphragm of the film material;

[0038] (2) Put the IMT film with the formed pattern into the vacuum optical plating equipment, and the electroplating increases the transparent plating or color plating;

[0039] (3) Put the printed IMT film on the hot-pressing mold, heat it with a hot press, and stretch it into the shape required by the customer;

[0040] (4) Use a stamping die to punch off the excess part of the edge of the stretched IMT film sheet;

[0041] (5) Tear off the IMT film PET protective film on the surface of the die-cut sheet, leaving only the acrylic UV layer and the printing layer;

[0042] (6) Put it into the injection mold for injection molding.

Embodiment 2

[0044] Use the UV transfer printing in-mold transfer printing decoration method of the present invention on the mobile phone shell, wherein the shell of the mobile phone is made of ABS / ABS+PC / PC material. The IMT film mentioned above is a raw material, which needs to be torn off before final injection molding. The process is shown in Figure 1, and the steps are as follows:

[0045] 1. Prepare the IMT film, and make acrylic UV pattern forming on the other side of the non-PET diaphragm of the film material.

[0046] Take the desired texture effect mold, pour acrylic glue on the mold, then take the IMT film non-PET film and put it on the mold, use the dust roller to flatten the acrylic back and forth on the film, and then put the mold into the UV tunnel Use a UV lamp to light-cure the acrylic. After light-curing, tear off the IMT film from the mold. The total thickness of the lines is 0.001-0.005MM, the peak energy of UV light-curing is 400-1000MJ, and the light-curing time is 3...

Embodiment 3

[0055] Use the UV transfer printing in-mold transfer printing decoration method of the present invention on the palmtop computer shell, and the shell of the palmtop computer is made of ABS material. The IMT film mentioned above is a raw material, which needs to be torn off before final injection molding.

[0056] The process steps are as follows:

[0057] 1. Prepare the IMT film, and make acrylic UV pattern forming on the other side of the non-PET diaphragm of the film material.

[0058] Take the desired texture effect mold, pour acrylic glue on the mold, then take the IMT film non-PET film and put it on the mold, use the dust roller to flatten the acrylic back and forth on the film, and then put the mold into the UV tunnel The acrylic is light-cured with a UV lamp. After light-curing, the IMT film is torn off from the mold. The total thickness of the lines is 0.003MM, the peak energy of UV light-curing is 1200MJ, and the light-curing time is 4 seconds.

[0059] 2. Put the I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com