Laminate adhesive, and laminate and rechargeable battery using same

An adhesive and composition technology, applied in the field of lamination adhesives, can solve the problems of inability to be used as a sealing film, low electrolyte resistance, interlayer peeling, etc., and achieve excellent resistance, excellent adhesion, good The effect of moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

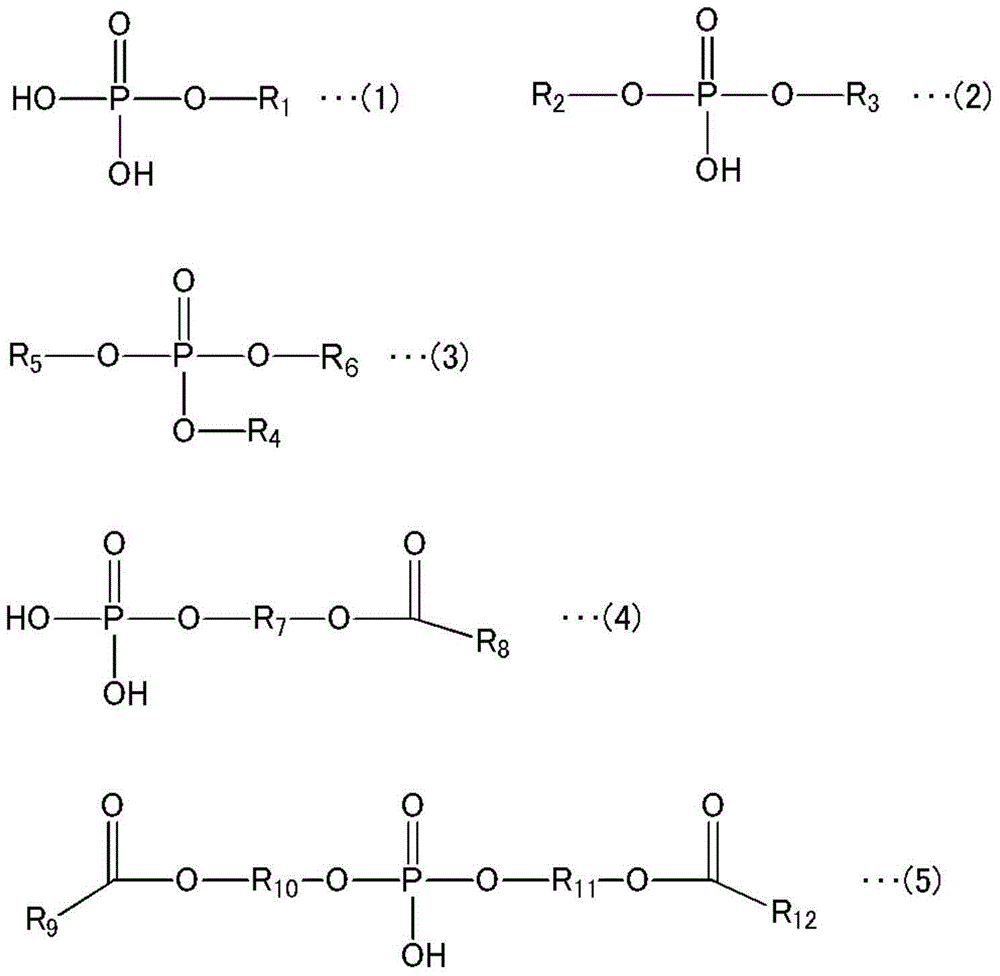

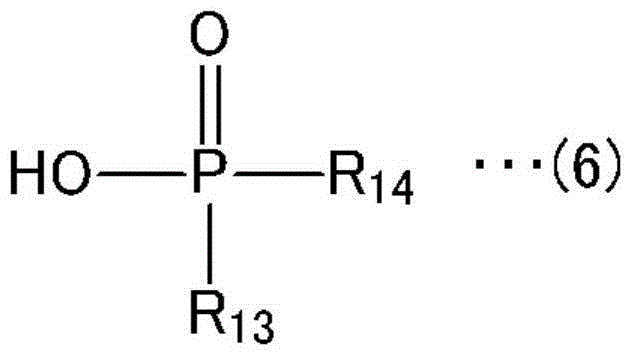

Method used

Image

Examples

Embodiment

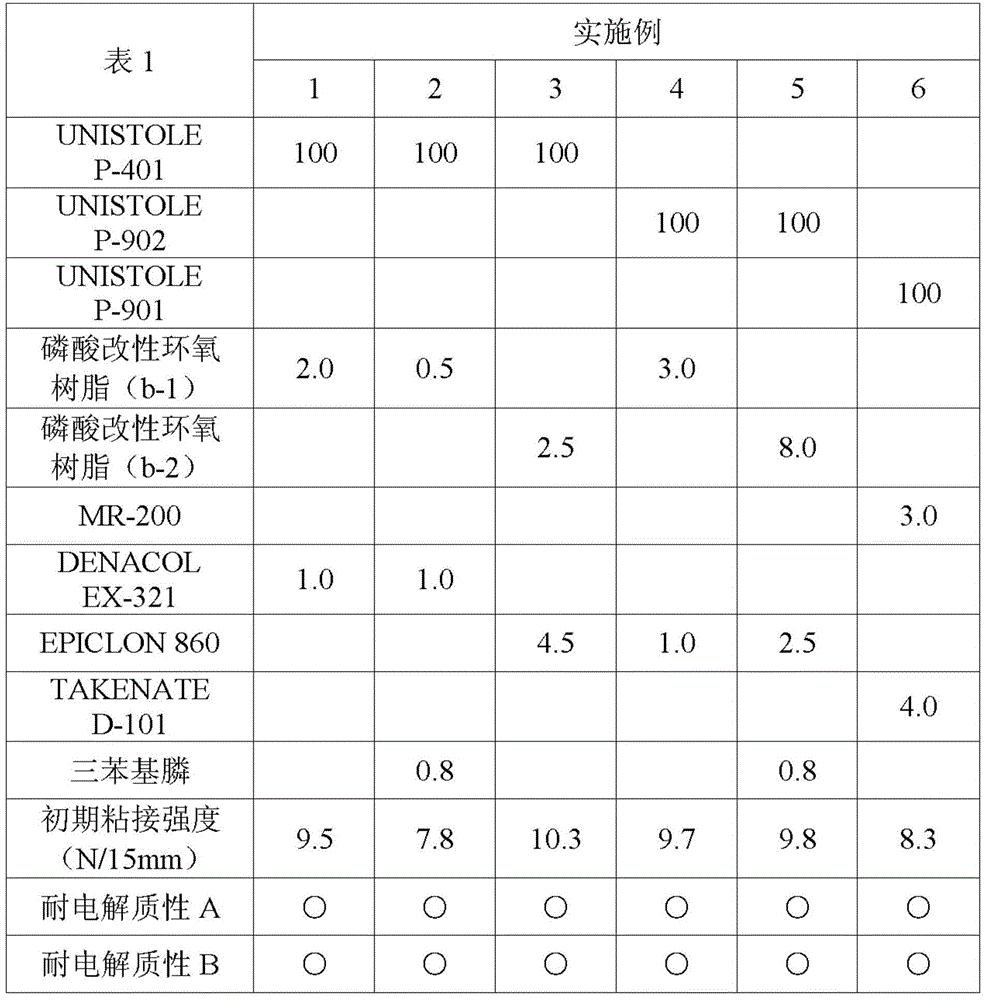

[0078] Hereinafter, the present invention will be described in detail with reference to Examples and Comparative Examples.

Synthetic example 1

[0079] Synthesis example 1 (synthesis example of phosphoric acid-modified epoxy resin (B))

[0080] Using sodium hydroxide as a catalyst, 600 parts of "EPICLON 850" (manufactured by DIC Co., Ltd., epoxy equivalent 185) and 250 parts of bisphenol A produced by epichlorohydrin and bisphenol A were used to obtain epoxy resin by a conventional method. Epoxy resin with an equivalent weight of 900. Gained epoxy resin was dissolved in 400 / 200 / 200 parts of xylene / ethylene glycol monobutyl ether / 1-butyl alcohol respectively, and 24 parts of 89% phosphoric acid were added dropwise several times at 80°C to carry out 10 hours of reaction, after confirming that there is no change in viscosity, adjust until the non-volatile content reaches 50% with ethylene glycol monobutyl ether, and then obtain the phosphoric acid modified epoxy resin (b-1) with a viscosity (25° C.) of W .

Synthetic example 2

[0081] Synthesis example 2 (synthesis example of phosphoric acid-modified epoxy resin (B))

[0082] 545.5 parts of "jER 1001" (BPA type epoxy resin manufactured by Mitsubishi Chemical Co., Ltd., epoxy equivalent 475) and diethylene glycol di 259.0 parts of methyl ether were heated and dissolved, and the temperature was raised to 80°C. After dissolution, 59.7 parts of acrylic acid was added at 80°C, followed by 0.6 parts of dibutylhydroxytoluene and 2.4 parts of triphenylphosphine, and stirred while raising the temperature to 110°C over 1 hour. Keep at 110°C for 3 hours to continue the reaction. When the acid value reaches below 1.0 mg KOH / g, lower the temperature to 80°C, and continuously drop 12.1 parts of 85% phosphoric acid and 70.2 parts of diglyme in 1 hour. composed mixture. Continue to react at 80° C. for 4 hours after the dropwise addition, and then add 50.5 parts of diethylene glycol dimethyl ether, thus obtaining a non-volatile component of 64.0% and a phosphoric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com