Method for preparing nanometer powdered carbon for fertilizer

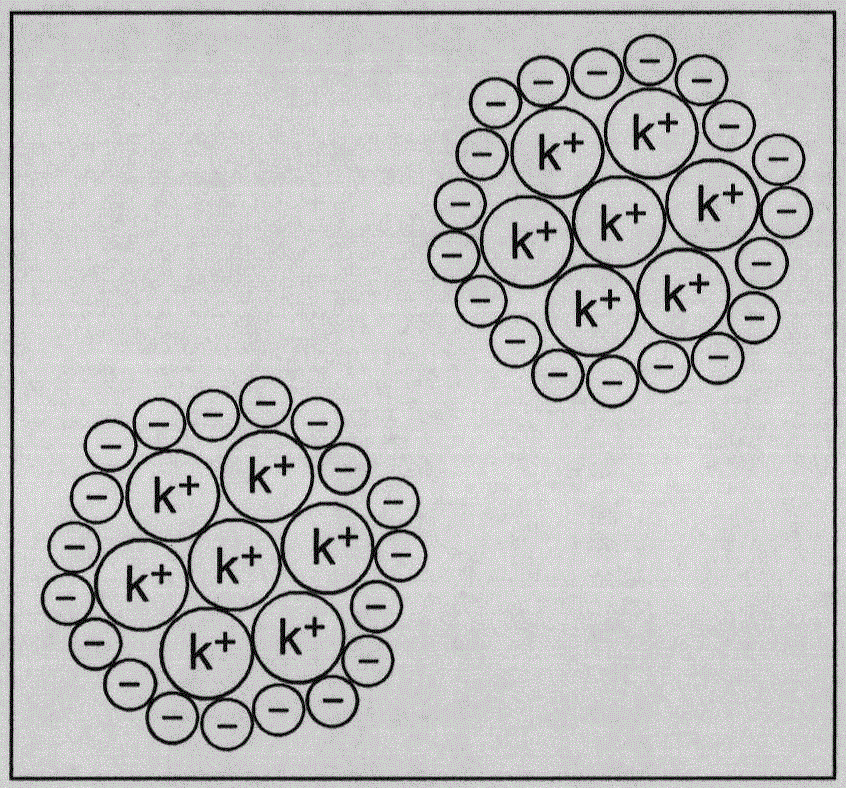

A technology of nano-carbon powder and nano-carbon sol, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, and can solve problems such as the inability to prepare ultra-fine carbon particles and the application of fertilizers in industrial production. Achieve the effect of increasing crop yield, low production cost and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

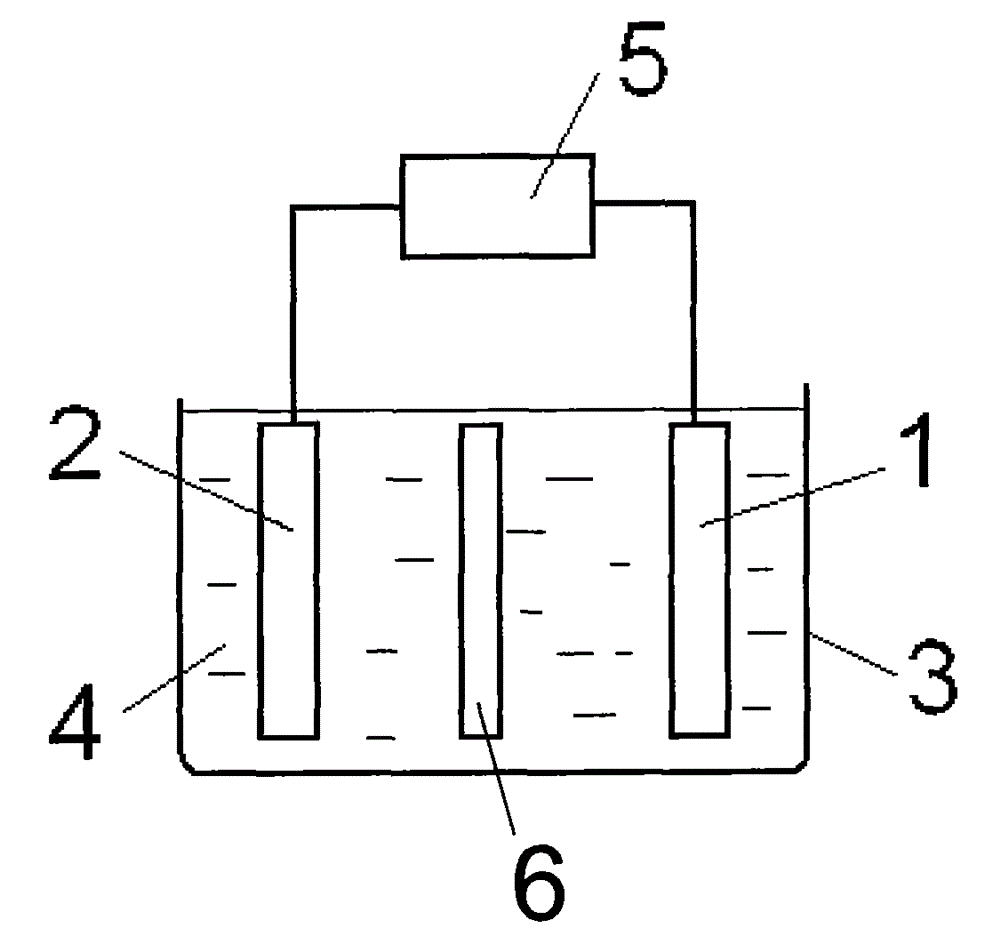

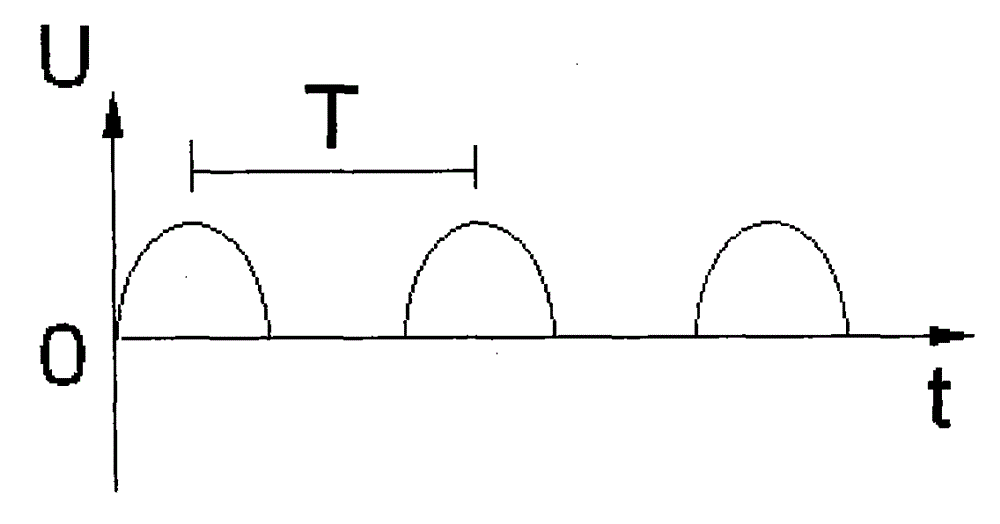

[0052] Take 3 high-purity graphite carbon plates (300mm×300mm×30mm, commercially available) as anode 1, cathode 2 and separator 6 respectively, according to figure 1 To form a system, the distance between the opposing surfaces of the anode 1 and the cathode 2 is 50 mm, and the separator 6 is arranged at equal intervals with the anode 1 and the cathode 2 . Pulse power supply 5 generates as figure 2 For the pulse voltage shown, the pulse frequency is 50Hz, and the effective voltage is 12V-15V.

[0053] Sodium chloride was added to deionized water to adjust the resistance of the solution so that when the effective value of the pulse voltage was 12V, the current of the system was 30A.

[0054] The pulse voltage was applied for 5 days to obtain a nano-carbon sol with a concentration of about 0.5% by weight.

[0055] Take 1 kg of the obtained nano carbon sol. 5 g KH 2 PO 4 The crystals are added to the above-mentioned nano-carbon sol at normal temperature, and mixed evenly, so...

Embodiment 2

[0057] Take 3 high-purity graphite carbon plates (300mm×300mm×30mm, commercially available) as anode 1, cathode 2 and separator 6 respectively, according to figure 1 To form a system, the distance between the opposing surfaces of the anode 1 and the cathode 2 is 50 mm, and the separator 6 is arranged at equal intervals with the anode 1 and the cathode 2 . Pulse power supply 5 generates as figure 2 For the pulse voltage shown, the pulse frequency is 50Hz, and the effective voltage is 12V-15V.

[0058] Sodium chloride was added to the deionized water to adjust the resistance of the solution so that when the effective value of the pulse voltage was 12V, the current of the system was 20A.

[0059] The pulse voltage was applied for 5 days to obtain a nano-carbon sol with a concentration of about 0.3% by weight.

[0060] Take 1 kg of the obtained nano carbon sol. 3 g KH 2 PO 4 The crystals are added to the above-mentioned nano-carbon sol at normal temperature, and mixed evenly...

Embodiment 3

[0067] The nano-carbon powder prepared in Example 1 is added into the urea nitrogen fertilizer at a ratio of 0.3% by weight, and the nano-carbon fertilizer can be obtained after mixing evenly. Applying the obtained nano-carbon fertilizer to field rice cultivation, compared with the application of ordinary urea nitrogen fertilizer that does not include nano-carbon, the fertilization amount of nano-carbon fertilizer only needs 70% of the original fertilization amount, while the rice yield has increased by 5% -15%.

[0068] It can be seen that the nano-carbon powder prepared by the method of the present invention can be applied to various fertilizers, thereby further increasing the yield of crops while reducing the amount of fertilizer applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com