Composite foaming agent for rigid PVC foam material

A technology of composite foaming agent and foaming material, applied in the field of foaming agent, can solve the problems that it is difficult to meet the requirements of the processing technology of rigid PVC foaming materials, the conditions of processing and molding are difficult to control, and the decomposition of PVC resin. There is no sudden outgassing, the processing conditions are easy to control, and the decomposition rate is gentle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A kind of composite foaming agent for rigid PVC foaming material, is made up of the following raw materials of weight part:

[0032] Azodicarbonamide 8 parts

[0033] Diethyl azodicarboxylate 3 parts

[0034] 2.5 parts of 4,4-disulfonylhydrazide diphenyl ether

[0035] Sodium Lauryl Sulfate 1.2 parts

[0036] Sodium bicarbonate 1.5 parts

[0037] 1.8 parts of zinc carbonate

[0038] 2.5 parts of urea

[0039] 0.6 parts of lead stearate

[0040] 3 parts citric acid

[0041] 16 parts of ethylene glycol propyl ether

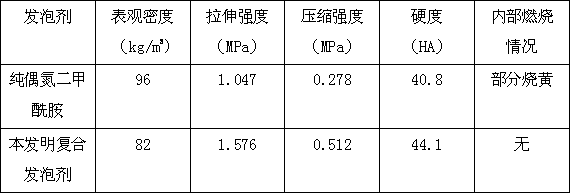

[0042] The composite foaming agent of the present invention is a novel foaming agent with excellent comprehensive performance. In order to verify the above results, a comparative experimental study was carried out, using pure azodicarbonamide and the composite blowing agent of the present invention as blowing agents to study their influence on the performance of rigid PVC foam materials, and the test results are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com