Production method of heat pipe with porous aluminum core

A porous aluminum and heat pipe technology, applied in the field of heat pipes, can solve the problem of destroying the porous core structure and achieve the effect of increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a heat pipe with a porous aluminum core, comprising the steps of:

[0027] 1) Preparation of NaCl particles with a particle size of 20 μm:

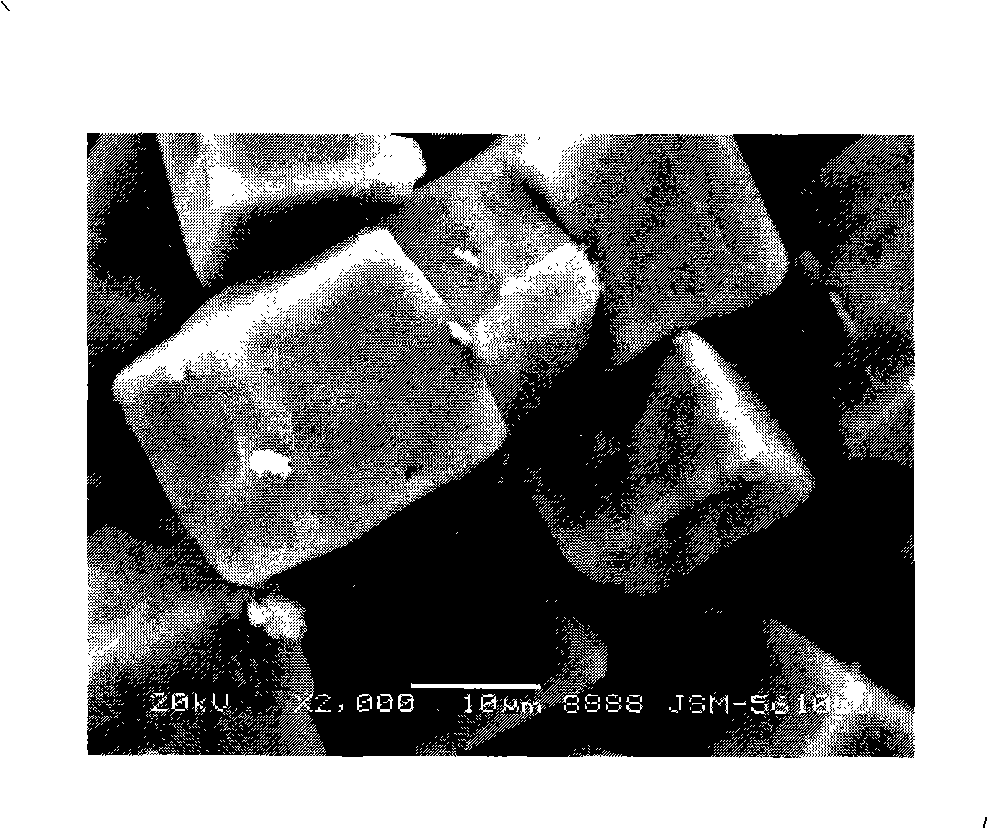

[0028] Prepare salt with an original particle size of 200-400 μm into a supersaturated salt solution, and then add supersaturated salt solution to the mixed solution of alcohol and acetone according to the volume ratio of supersaturated salt solution: alcohol: acetone = 1:0.5:1. Saturated salt solution, stirred for 60 minutes, and baked at 80°C for 2 hours to obtain NaCl particles with a particle size of 20 μm; image 3 shown;

[0029] 2) Selection of raw materials: 20 μm NaCl particles account for 60% by weight, 6 μm Al powder accounts for 40% by weight, select 20 μm NaCl particles and 6 μm Al powder for later use;

[0030] 3) Mix 20 μm NaCl particles and 6 μm Al powder to obtain mixed powder; place the mixed powder on a 2 mm thick aluminum substrate, the thickness of the mixed powder on the aluminum subst...

Embodiment 2

[0033] A method for preparing a heat pipe with a porous aluminum core, comprising the steps of:

[0034] 1) Preparation of NaCl particles with a particle size of 5 μm:

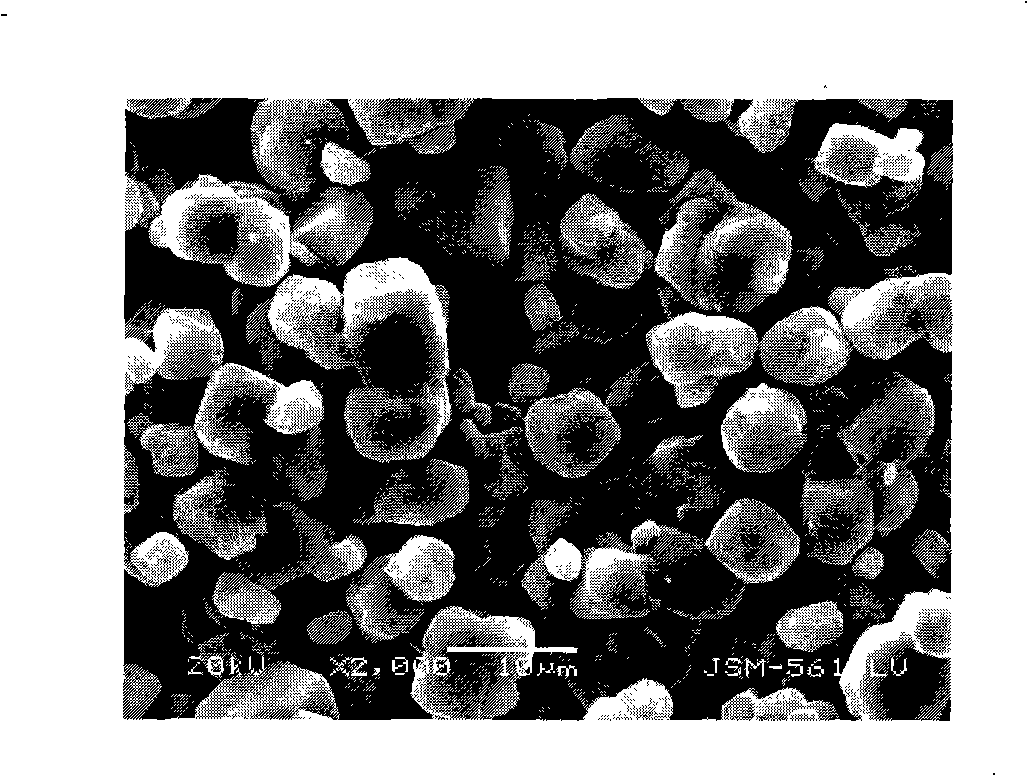

[0035] Salt with an original particle size of 200-400 μm is prepared into a supersaturated saline solution, and then according to the ratio of supersaturated saline solution:alcohol volume ratio=1:1, the supersaturated saline solution is added to the alcohol, and the solution is allowed to stand for 30 minutes. Bake at 80°C for 2 hours to obtain NaCl particles with a particle size of 5 μm, such as figure 1 shown;

[0036] 2) Selection of raw materials: 5 μm NaCl particles account for 60% by weight, 6 μm Al powder accounts for 40% by weight, select 5 μm NaCl particles and 6 μm Al powder for later use;

[0037] 3) Mix 5 μm NaCl particles and 6 μm Al powder to obtain a mixed powder; place the mixed powder on a 2 mm thick aluminum substrate, the thickness of the mixed powder on the aluminum substrate is 2 mm, an...

Embodiment 3

[0040] A method for preparing a heat pipe with a porous aluminum core, comprising the steps of:

[0041] 1) Preparation of NaCl particles with a particle size of 10 μm:

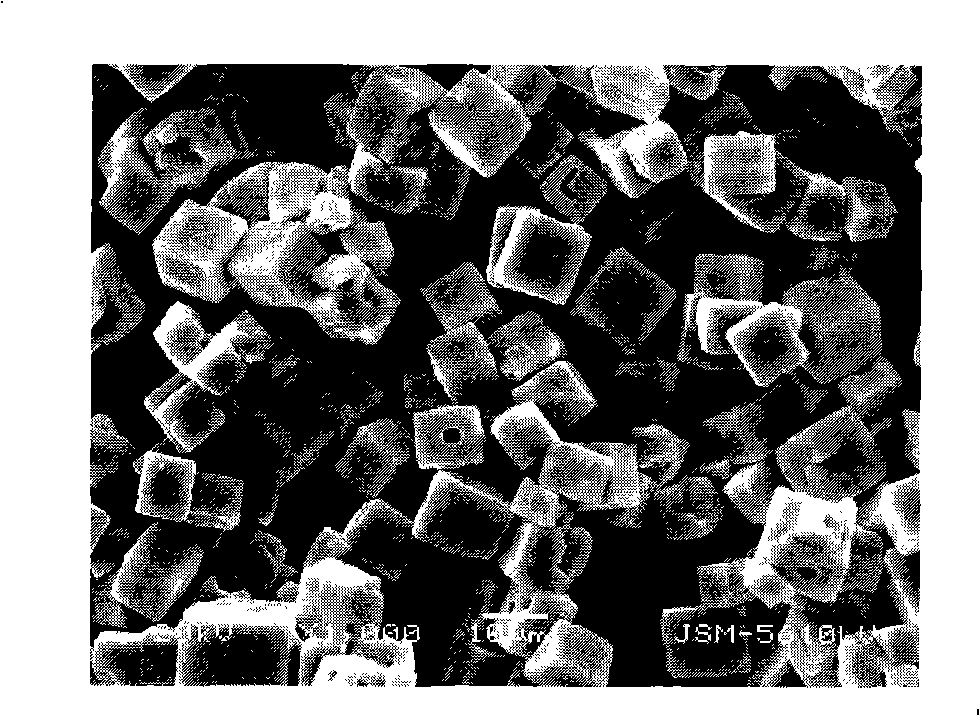

[0042] Prepare salt with an original particle size of 200-400 μm into a supersaturated salt solution, then add supersaturated salt solution to the alcohol according to the ratio of supersaturated salt solution: alcohol volume ratio = 1:1, stir for 30 minutes, and 80 °C for 2 hours to obtain NaCl particles with a particle size of 10 μm, such as figure 2 shown;

[0043] 2) Selection of raw materials: 58% by weight of 10 μm NaCl particles and 42% by weight of 5 μm Al powder, select 10 μm NaCl particles and 5 μm Al powder for later use;

[0044] 3) Mix 10 μm NaCl particles and 5 μm Al powder to obtain mixed powder; place the mixed powder on a 1 mm thick aluminum substrate, the thickness of the mixed powder on the aluminum substrate is 1 mm, and then use pulse current technology for sintering, The sintering proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com