Preparation method for copper aluminate spinel porous block

A technology of spinel and copper aluminate is applied in the field of preparation of copper aluminate spinel porous block, which can solve the problem of no patent report on copper aluminate spinel porous block, and achieves high porosity, Simple process and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, a preparation method of a copper aluminate spinel porous block, polyethylene oxide is a phase separation inducer, citric acid monohydrate is a complexing agent, and 1,2-propylene oxide is a gel accelerator, Follow the steps in order:

[0038] 1), 0.075g of polyethylene oxide was dissolved in a solvent (the solvent consisted of 3.7ml of deionized water and 2.5ml of absolute ethanol), and stirred for 10min to obtain a uniform solution (phase separation inducer solution);

[0039] 2), 0.005mol copper chloride dihydrate, 0.01mol (2.41g) aluminum chloride hexahydrate and 3g citric acid (citric acid monohydrate) are dissolved in the solution obtained in step 1), stirring chlorine dihydrate at room temperature Copper chloride, aluminum chloride hexahydrate and citric acid were all dissolved to obtain a dark green clear solution;

[0040] 3) Slowly add 2.4ml of 1,2-propylene oxide to the dark green clear solution obtained in step 2) dropwise (2 minutes to complet...

Embodiment 2

[0049]Example 2, the preparation method of copper aluminate spinel porous block, change the heat treatment temperature in step 7) of Example 1 from 600°C to 800°C, and the rest are the same as Example 1.

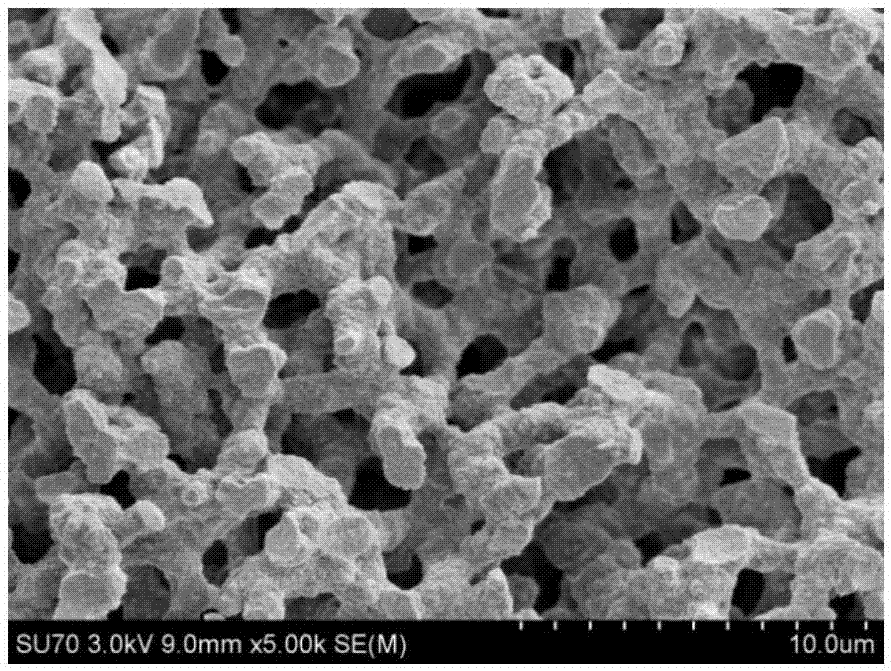

[0050] The prepared porous copper aluminate spinel porous block remains intact, and its internal microstructure is as follows: Figure 4 As shown, with a small amount of shrinkage, the co-continuous pore structure is not destroyed, and the porous copper aluminate spinel porous block can still be obtained, the porosity increases to 63.5%, the pore volume is 0.460ml / g, and the pore size distribution is 1.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com