Core-shell composite molecular sieve and application of core-shell composite molecular sieve to carbon dioxide separation

A composite molecular sieve, core-shell type technology, applied in the field of core-shell type composite molecular sieve materials, can solve the problem of low carbon dioxide adsorption selectivity, achieve high selectivity, improve adsorption selectivity, and realize the effect of environmental purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

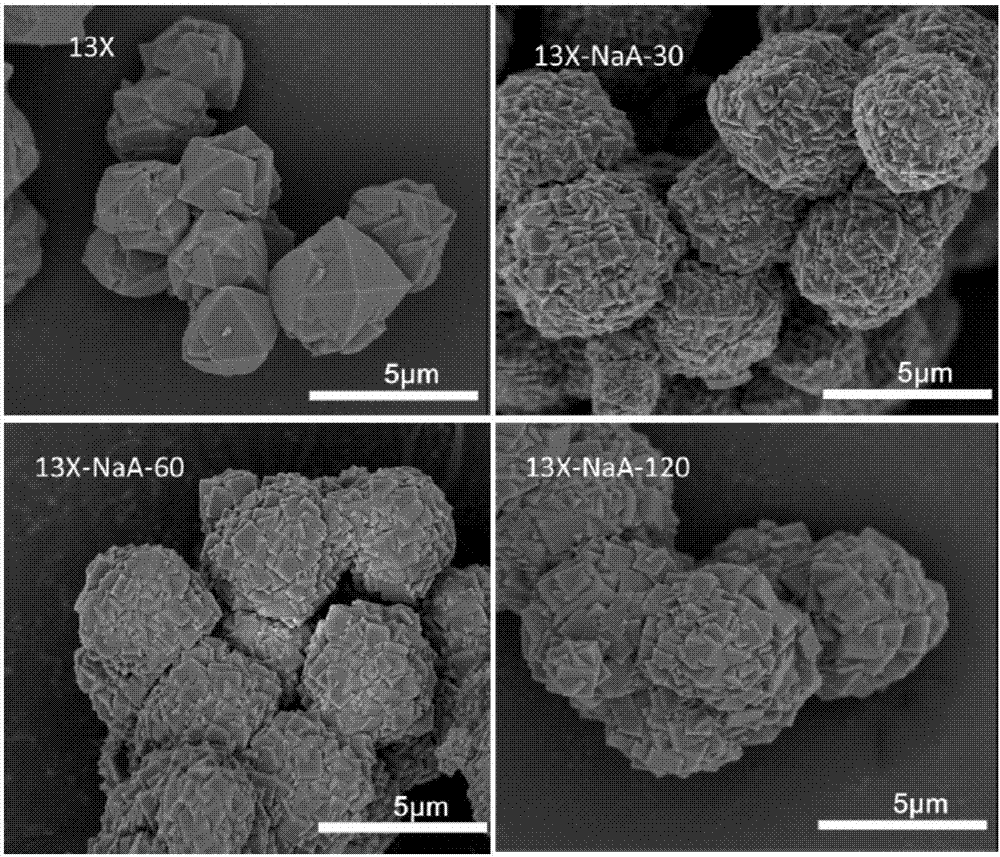

[0023] Example 1. Synthesis of 13X@NaA core-shell composite molecular sieve with crystallization time of 30 minutes

[0024] 13X was activated by heating at 500°C for 1 hour before use, and then activated by low-temperature plasma surface treatment for 10 minutes. Disperse 1 g of activated 13X powder in a certain amount of NaA precursor gel (1.9NaOH / 1.5NaAlO 2 / 3.5NaSiO 3 9H 2 O / 43H 2 O). Stir and mix well at 333K, transfer the mixture slurry to an autoclave and crystallize at 373K for 30 minutes. The sample was then filtered and washed 3 times with distilled water, dried at 383 K, and the obtained material was designated as 13X@NaA-30.

[0025] Such as figure 1 As shown, its scanning electron microscope picture shows that a stable core-shell structure 13X@NaA-30 has been generated

Embodiment 2

[0026] Example 2, Synthesis of 13X@NaA core-shell composite molecular sieve with crystallization time of 60 minutes

[0027] 13X was activated by heating at 500°C for 1 hour before use, and then activated by low-temperature plasma surface treatment for 10 minutes. Disperse 1 g of activated 13X powder in a certain amount of NaA precursor gel (1.9NaOH / 1.5NaAlO 2 / 3.5NaSiO 3 9H 2 O / 43H 2 O). Stir and mix well at 333K, transfer the mixture slurry to an autoclave and crystallize at 373K for 60 minutes. The sample was then filtered and washed 3 times with distilled water, dried at 383 K, and the obtained material was designated as 13X@NaA-60.

[0028] Such as figure 1 As shown, its scanning electron microscope picture shows that a stable core-shell structure 13X@NaA-60 has been generated

Embodiment 3

[0029] Example 3, Synthesis of 13X@NaA core-shell composite molecular sieve with crystallization time of 120 minutes

[0030] 13X was activated by heating at 500°C for 1 hour before use, and then activated by low-temperature plasma surface treatment for 10 minutes. Disperse 1 g of activated 13X powder in a certain amount of NaA precursor gel (1.9NaOH / 1.5NaAlO 2 / 3.5NaSiO 3 9H 2 O / 43H 2 O). Stir and mix well at 333K, transfer the mixture slurry to an autoclave and crystallize at 373K for 120 minutes. The sample was then filtered, washed 3 times with distilled water, and dried at 383 K, and the resulting material was designated as 13X@NaA-120.

[0031] Such as figure 1 As shown, its scanning electron microscope picture shows that a stable core-shell structure 13X@NaA-120 has been generated

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com