Preparation of porous sericin sponge material

A silk fibroin, three-dimensional porous technology is applied in the field of preparing three-dimensional porous materials from natural biological macromolecules silk fibroin, which can solve the problems of uniformity, flexibility, insufficient porosity and water absorption of the preparation process, and achieve good elasticity and casting performance. Good, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: About 10g of pupa silkworm cocoons were immersed in 2L 0.5% NaHCO 3 In the solution, stir and boil for 55 minutes, then take it out, and wash it with deionized water. After repeating the above operation once, dry the silk at 65°C for 24 hours and put it in a desiccator for later use.

[0029]Weigh 3 g of the degummed silk after the above treatment, dissolve it in 100 mL of a BrLi solution with a concentration of 9.5 mol / L, and dissolve it under low-speed magnetic stirring at a constant temperature of 45°C. Pour the protein solution into a cellulose dialysis bag and dialyzed with deionized water for three days to obtain a silk protein aqueous solution with a concentration of 2.32%, and adjust the silk protein concentration to 1.0%.

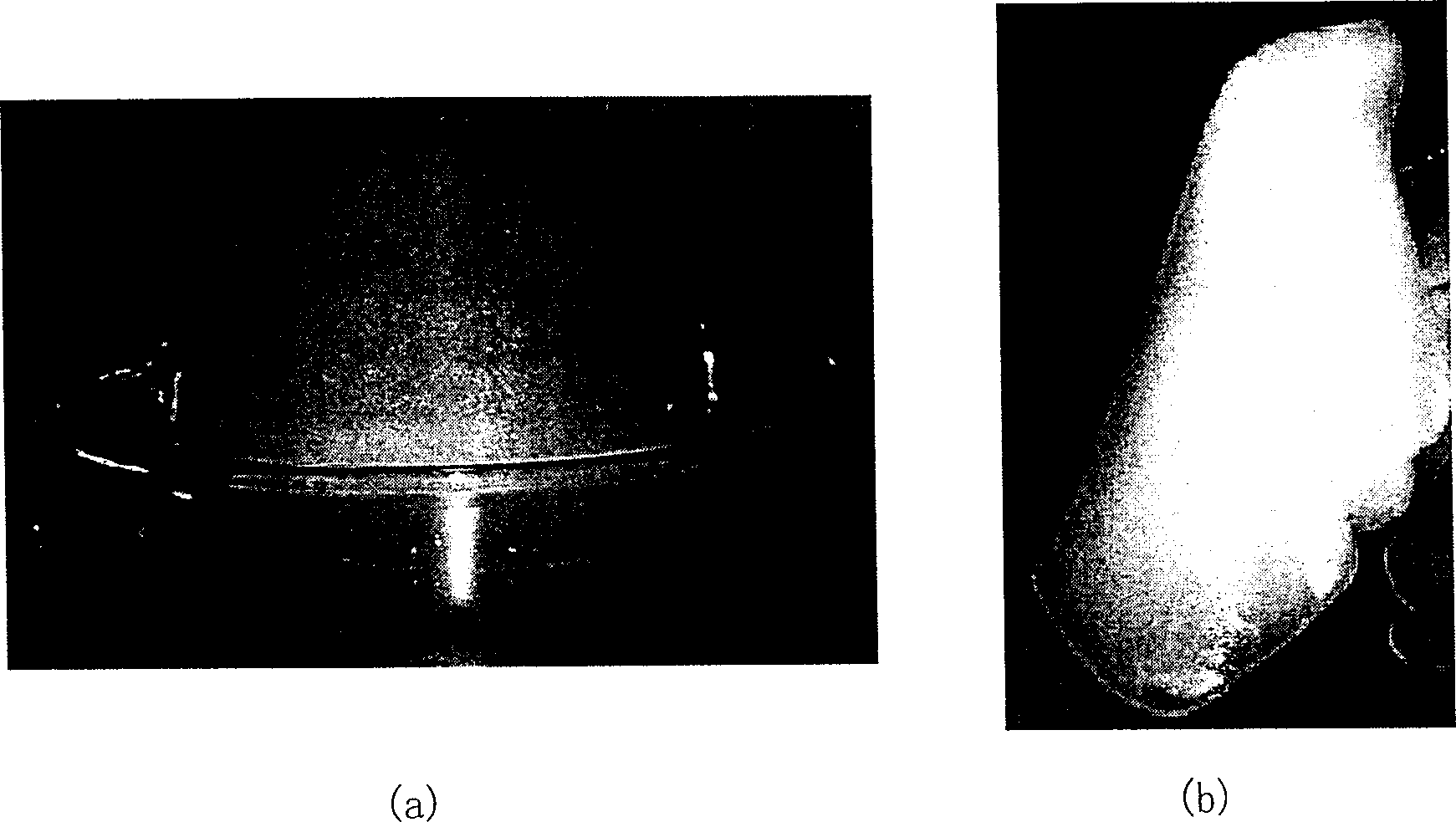

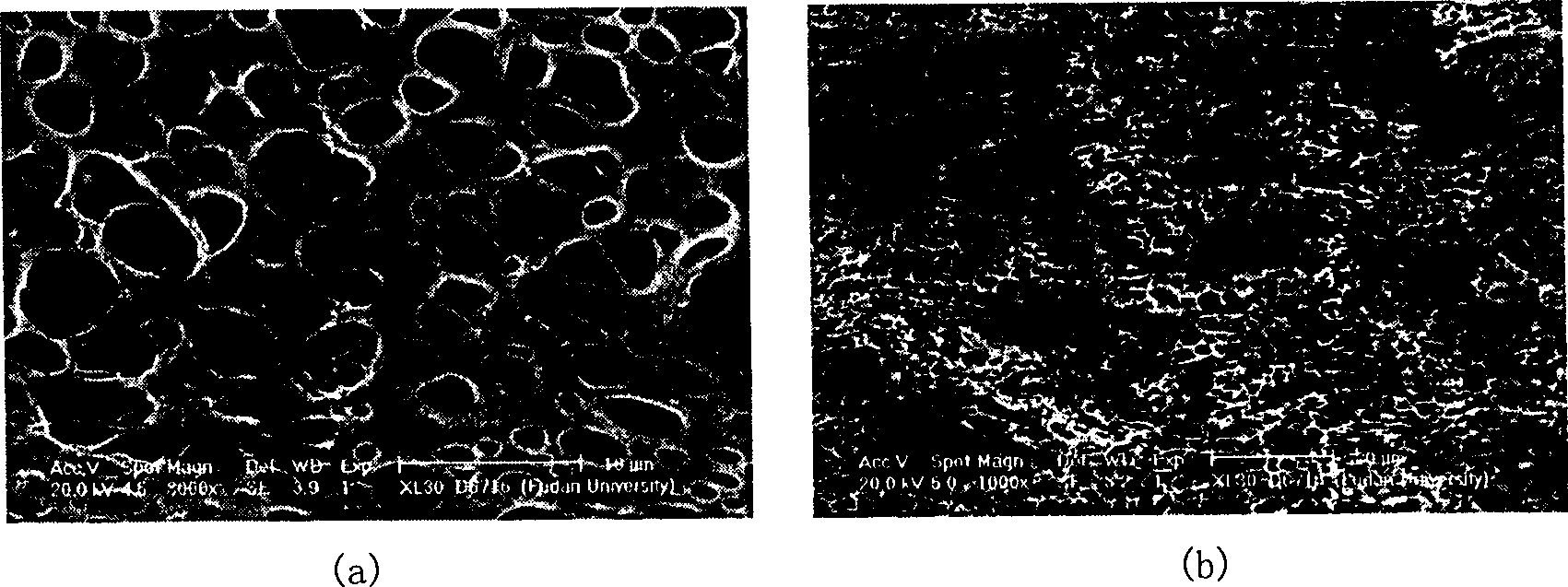

[0030] Take 5 mL of the above silk protein solution, add 3 mL of n-butanol dropwise under a constant-speed stirring rod in a constant temperature water bath at 25°C, pour it into a plastic box after stabilizing for 2 minutes, and then...

Embodiment 2

[0031] Example 2: Immerse about 30g of waste silk into 3L 0.5% Na 2 CO 3 In the solution, stir and boil for 45 minutes, then take it out and wash it with deionized water. After repeating the above operation twice, the silk is dried at 65°C and put into the dryer for later use.

[0032] Weigh 6 g of the degummed silk after the above treatment and dissolve it in 100 mL of a BrLi solution with a concentration of 10.0 mol / L, and dissolve under low-speed magnetic stirring at a constant temperature of 45°C. Pour the protein solution into a cellulose dialysis bag, dialyzed with deionized water for three days to obtain a silk protein aqueous solution with a concentration of 8%, and then dilute to adjust the silk protein solution concentration to 5%.

[0033] Take 10 mL of the above-mentioned silk protein solution, add 5 mL of acetone dropwise with constant stirring in a constant temperature water bath at 25°C, stabilize for 2 minutes, and freeze it in a low-temperature refrigerator at -30...

Embodiment 3

[0034] Example 3: About 20g of waste silk was immersed in 2L of 0.5mol / L boric acid-borax buffer solution, stirred and boiled for 60 minutes, then taken out, and washed with deionized water. After repeating the above operation once, the silk is dried at 65°C and placed in a desiccator for later use.

[0035] Weigh 12 g of the degummed silk after the above treatment, dissolve it in 100 mL of LiBr solution with a concentration of 10.0 mol / L, and dissolve it under low-speed magnetic stirring at a constant temperature of 45°C. Pour the protein solution into a cellulose dialysis bag and dialyzed with deionized water for three days to obtain a silk protein aqueous solution with a concentration of 11%, and adjust the silk protein concentration to 10% by dilution.

[0036] Take 10 mL of the above silk protein solution, add 10 mL of tert-butanol dropwise under a constant temperature water bath at 25°C, pour it into the ball after stabilizing for 2 minutes, and put it in a low-temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com