Opioid receptor partial agonist supported sustained release microsphere as well as preparation method and application thereof

A technology of opioid receptors and slow-release microspheres, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., which can solve the problems of side effects, research and drug effect interference, and bioavailability In order to avoid problems such as poor accuracy, it can achieve the effect of facilitating industrial scale-up production, ensuring repeatability, and improving drug loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

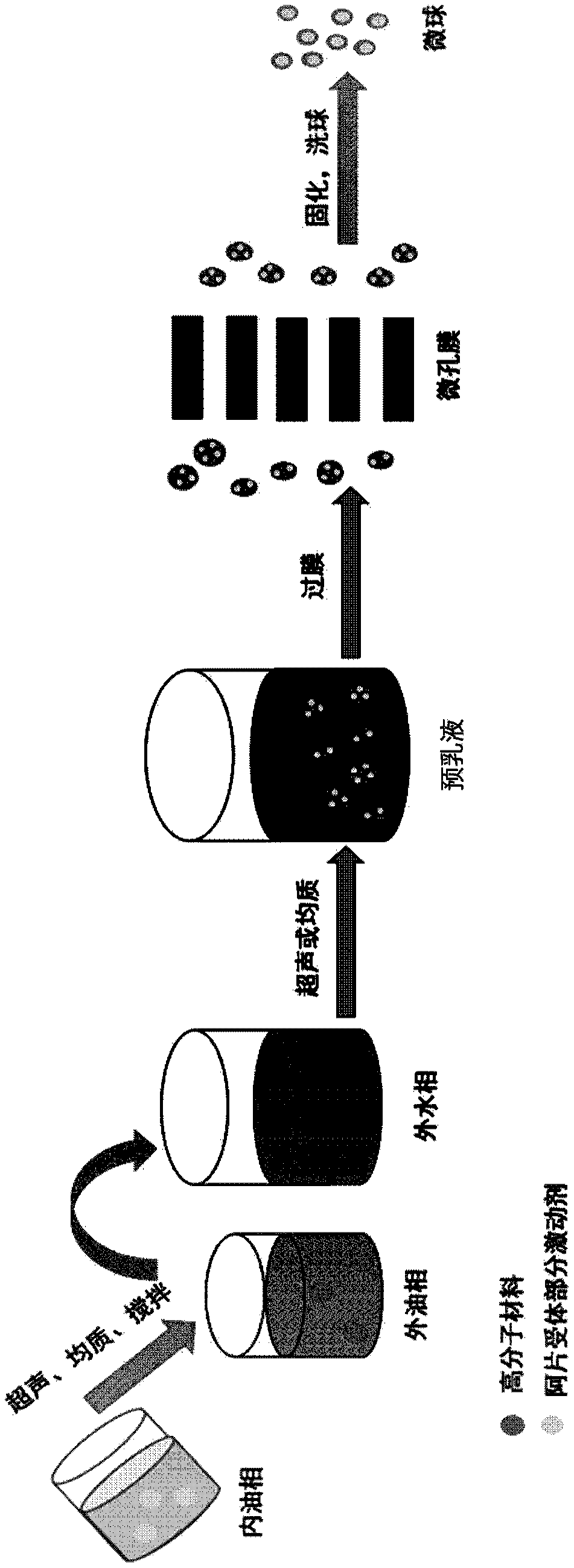

[0054] The invention also discloses a preparation method of slow-release microspheres loaded with an opioid receptor partial agonist, comprising the following steps:

[0055] Step A, dissolving the opioid receptor partial agonist (drug) in a first organic solvent to form an internal oil phase (O1);

[0056] Step B, dissolving the degradable polymer material in at least one second organic solvent to form an external oil phase (O2);

[0057] Step C, preparing by injecting the inner oil phase (O1) obtained in step A into the outer oil phase (O2) obtained in step B and uniformly mixing to form an O1 / O2 mixed dispersed phase;

[0058] Step D, adding the mixed oil phase obtained in step C to the external water phase (W) containing a stabilizer to form an O1 / O2 / W pre-emulsion;

[0059] Step E, passing the pre-emulsion obtained in step D through a microporous membrane under pressure to form a uniform O1 / O2 / W emulsion;

[0060] In step F, the homogeneous emulsion obtained in step E i...

Embodiment 1

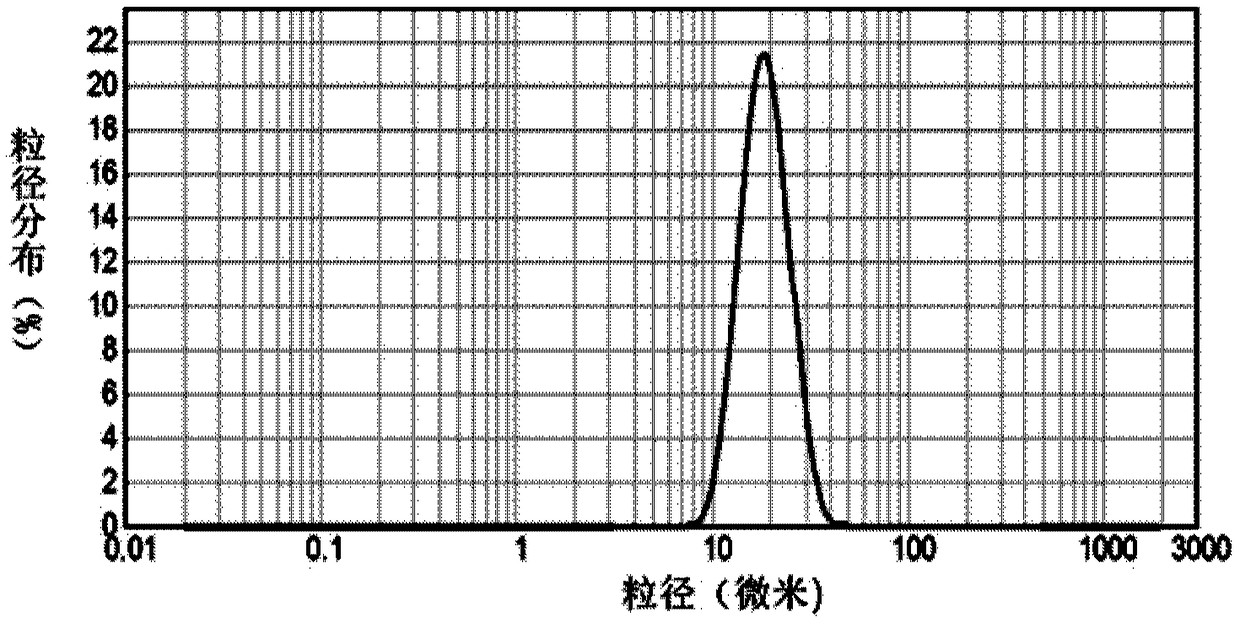

[0091] A hydrophilic and uniform porous membrane with a pore diameter of 35 μm is soaked in water to fully wet the porous membrane. Dissolve 100 mg of dezocine at a concentration of 25 mg / mL in 4 mL of ethanol as the internal oil phase (O1), and simultaneously add 1 g of polylactic acid-polyhydroxyl Acetic acid copolymer (PLGA) was dissolved in 10 mL of dichloromethane as the external oil phase (O2). Dissolve 1 g of polyvinyl alcohol (PVA) in 100 mL of distilled water and stir evenly as the external water phase. Add the inner oil phase to the outer oil phase and homogenize at 6000rpm, mix for 30s to obtain a uniformly mixed O1 / O2 mixed oil phase, then add the mixed oil phase to the outer water phase and continue to homogeneously emulsify for 3 minutes to obtain a pre-emulsion O1 / O2 / W, the pre-emulsion O1 / O2 / W is pressed through the microporous membrane device under the operating pressure of 300kPa (operating steps such as figure 1 shown), the emulsion was obtained, and the ...

Embodiment 2

[0093] A hydrophilic porous membrane with a uniform pore diameter of 30 μm is soaked in water to fully wet the porous membrane. 200 mg of pentazocine with a concentration of 50 mg / mL was dissolved in 4 mL of glycerol as the internal oil phase (O1), and 2 g of polylactic acid with a molecular weight of 10,000 (polylactic acid:polyglycolic acid=50:50) - Polyglycolic acid copolymer (PLGA) was dissolved in 10 mL of dichloromethane as the external oil phase (O2). Dissolve 1 g of polyvinyl alcohol (PVA) in 100 mL of distilled water and stir evenly as the external water phase (W). Add the inner oil phase to the outer oil phase and homogenize at 9000rpm, mix for 60s to obtain a mixed oil phase O1 / O2, then add the mixed oil phase to the outer water phase and continue to homogeneously emulsify for 5 minutes to obtain a pre-emulsion O1 / O2 / W. The pre-emulsion O1 / O2 / W was pressed through the microporous membrane device at an operating pressure of 600kPa to obtain an emulsion. The emulsion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com