Preparation method and product of multi-layer composite dual-drug-loaded microsphere having pH responsivity

A multi-layer composite and dual-drug loading technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulations, can solve problems that are difficult to meet clinical requirements and achieve good sustained release effect, improve the therapeutic effect, reduce the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

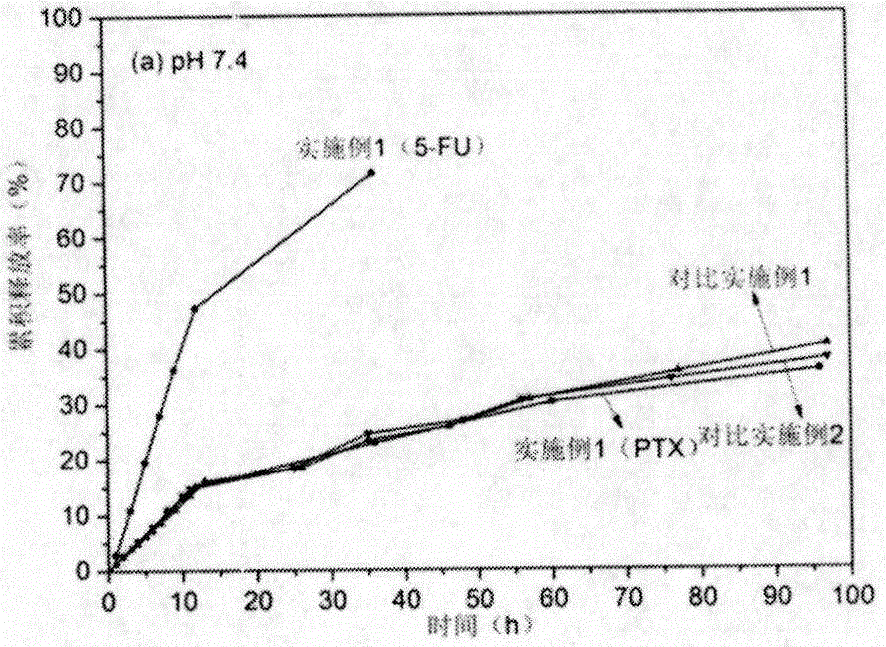

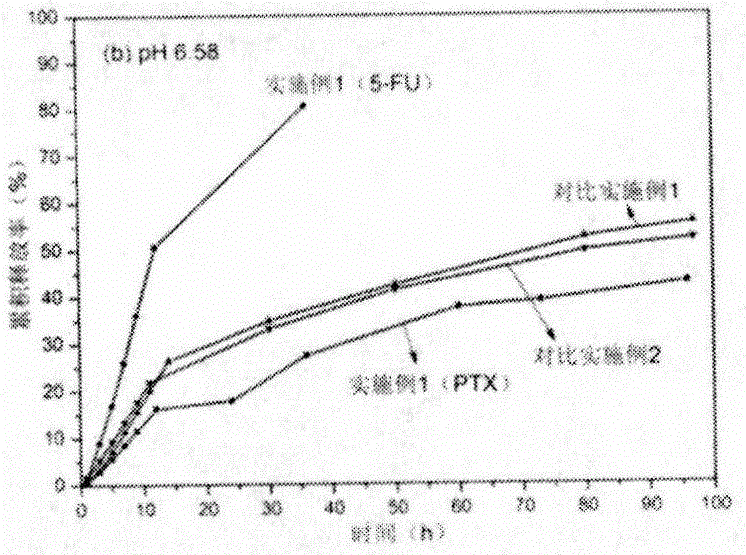

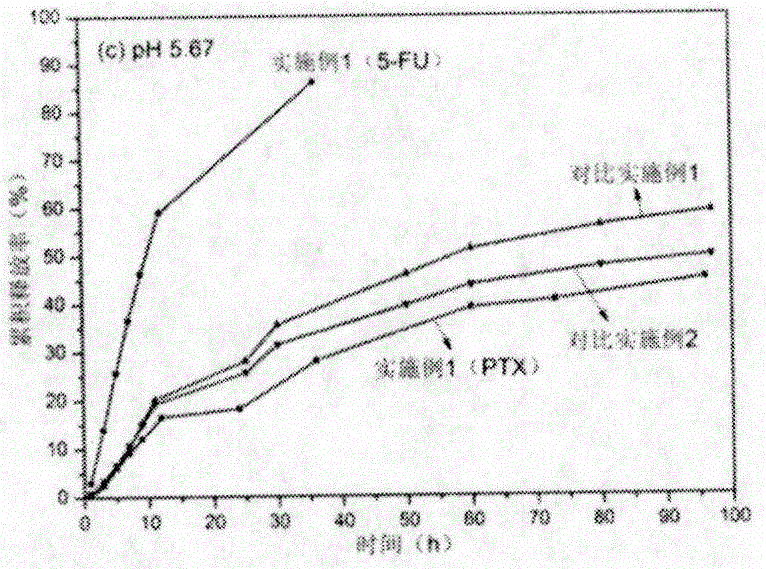

[0035] The invention provides a preparation method of a multi-layer double-loaded composite microsphere with pH response and a microsphere preparation thereof. Due to the distinguishable characteristics of the multilayer polymer microspheres, different drugs can be encapsulated (different drugs are selectively encapsulated between different polymer layers) and drug release can be controlled.

[0036] The self-assembly template of the drug-loaded microspheres is chitosan microspheres, and chitosan microspheres have become a drug-loaded microsphere preparation because of their characteristics such as targeting, sustained release, biodegradability and surface modification. Research hotspot, but because chitosan is a kind of natural degradable material with bioadhesiveness, the traditional preparation method has defects such as large size, poor dispersion of microspheres, and low encapsulation efficiency, so further improvement is needed. The present invention adopts A simple and ...

Embodiment 1

[0040] Weigh 0.12g chitosan and dissolve in 1% (v / v) acetic acid solution, stir and dissolve to obtain chitosan acetic acid solution. Tween-80 was added to the chitosan-acetic acid solution as the water phase. Dissolve 50 mg of paclitaxel in dichloromethane and add chitosan acetic acid solution and stir for 30 min to form oil-in-water (O / W) emulsion I. Add 0.1 mL of glutaraldehyde (concentration 25%) into liquid paraffin and drop into Span 80, stir for 30 min to form water-in-oil W / O emulsion II. After emulsion I and emulsion II were ultrasonically emulsified for 3 minutes, they were mixed and stirred for 40 minutes, and then heated to 40°C for 2 hours to crosslink and solidify.

[0041] Add 10 mL of a dextran-sodium hydroxide (sodium hydroxide concentration of 5 mg / mL) solution with a dextran concentration of 6 mg / mL dropwise into the chitosan microsphere suspension, and form a dextran / chitosan solution after 1 h of reaction. Sugar-loaded paclitaxel microsphere solution (DE...

Embodiment 2

[0044] Weigh 0.12g chitosan and dissolve in 1% (v / v) acetic acid solution, stir and dissolve to obtain chitosan acetic acid solution. Tween-80 was added to the chitosan-acetic acid solution as the water phase. An appropriate amount of 40 mg paclitaxel was dissolved in dichloromethane and added to chitosan acetic acid solution and stirred for 30 min to form oil-in-water (O / W) emulsion I. Add 0.1 mL of glutaraldehyde (concentration: 25%) into liquid paraffin and drop into Span 80, stir for 30 min to form water-in-oil W / O emulsion II. After emulsion I and emulsion II were ultrasonically emulsified for 3 minutes, the two were mixed and stirred for 40 minutes, then the temperature was raised to 40°C, and the cross-linking and curing were performed for 2 hours.

[0045] Add 12 mL of dextran-sodium hydroxide (sodium hydroxide concentration 5 mg / mL) solution with a dextran concentration of 6 mg / mL dropwise into the chitosan microsphere suspension, and form dextran / chitosan after 1 h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com