Sustained-release microgranules, method for preparing same and application of sustained-release microgranules

A technology of slow-release microparticles and microparticles, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve problems such as unfavorable, unstable release, and aggregation and precipitation of active substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

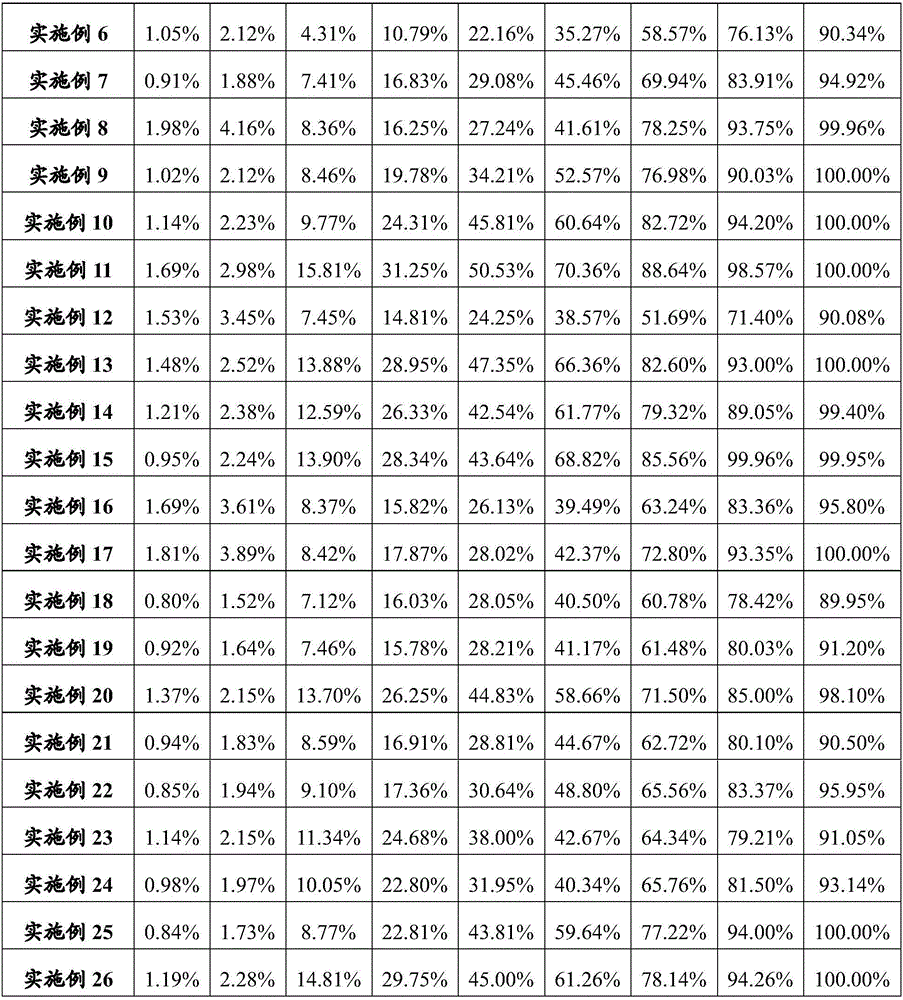

[0104] Example 1 Preparation of albiglutide / PLGA microparticles

[0105] (1) Preparation of solid dispersion

[0106] Dissolve 0.90g PLGA (molecular weight 25kDa, monomer ratio 65 / 35, carboxyl-terminated) in about 6.00mL glacial acetic acid, then add 0.10g albiglutide acetate, dissolve under vortex, and then slowly pour into a stirring In water ether (6°C), a white precipitate was produced, collected the white precipitate and extracted about 5 times with anhydrous ether, dried in a vacuum oven for 24 hours (10°C) after collecting the precipitate, to obtain a solid dispersion.

[0107] (II) Preparation of microparticles

[0108] The solid dispersion obtained in step I was uniformly dispersed in about 6.00 g of dichloromethane to obtain an internal oil phase, and then the internal oil phase was injected into 230 mL of 0.05% (w / w) lecithin / peanut oil that had been pre-warmed to about 4°C solution, and use a high-speed homogenizer to prepare S / O / O emulsion (rotor speed about 3...

Embodiment 2

[0109] Example 2 Preparation of dulaglutide / PLGA microparticles

[0110](1) Preparation of solid dispersion

[0111] Dissolve 0.95g PLGA (molecular weight 30kDa, monomer ratio 50 / 50, carboxyl-terminated) in about 7.92mL acetonitrile, then add 0.05g dulaglutide acetate, dissolve under vortex, and then slowly pour into the cyclohexane under stirring In alkanes (6°C), a white precipitate was produced, which was collected and extracted about 5 times with cyclohexane. After the collected precipitate was dried in a vacuum oven for 24 hours (10°C), a solid dispersion was obtained.

[0112] (II) Preparation of microparticles

[0113] The solid dispersion obtained in step I was uniformly dispersed in about 7.92 g of chloroform to obtain an internal oil phase, and then the internal oil phase was injected into 420 mL of a 0.1% (w / w) lecithin / liquid paraffin solution that had been pre-warmed to about 5°C , and use a high-speed homogenizer to prepare S / O / O emulsion (rotor speed about 3...

Embodiment 3

[0114] Example 3 Preparation of follicle stimulating hormone / PLA microparticles

[0115] (1) Preparation of solid dispersion

[0116] Dissolve 0.97g PLA (molecular weight 20kDa, terminal ester group) in about 5.39mL dimethyl sulfoxide, then add 0.03g follicle-stimulating hormone acetate, 0.05g xylitol and 0.03g zinc chloride, dissolve under vortex, Then it is slowly injected into n-hexane (8°C) under stirring to produce a white precipitate, which is collected and extracted about 5 times with n-hexane, and dried in a vacuum oven for 24 hours (10°C) after the precipitate is collected to obtain Solid dispersion.

[0117] (II) Preparation of microparticles

[0118] The solid dispersion obtained in step I was uniformly dispersed in a mixed solution of about 5.39 g of dichloromethane and chloroform to obtain an internal oil phase, and then the internal oil phase was injected into 410 mL of 0.25% (w / w ) lecithin / soybean oil solution, and emulsified using a turbine homomixer to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com