Amorphous alloy cellular material and preparation method thereof

A technology of amorphous alloy and honeycomb material, applied in the field of amorphous alloy honeycomb material and its preparation, can solve the problems of high cost, unstable performance, low connection strength, etc., and achieve the effects of high strength, convenient porosity, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

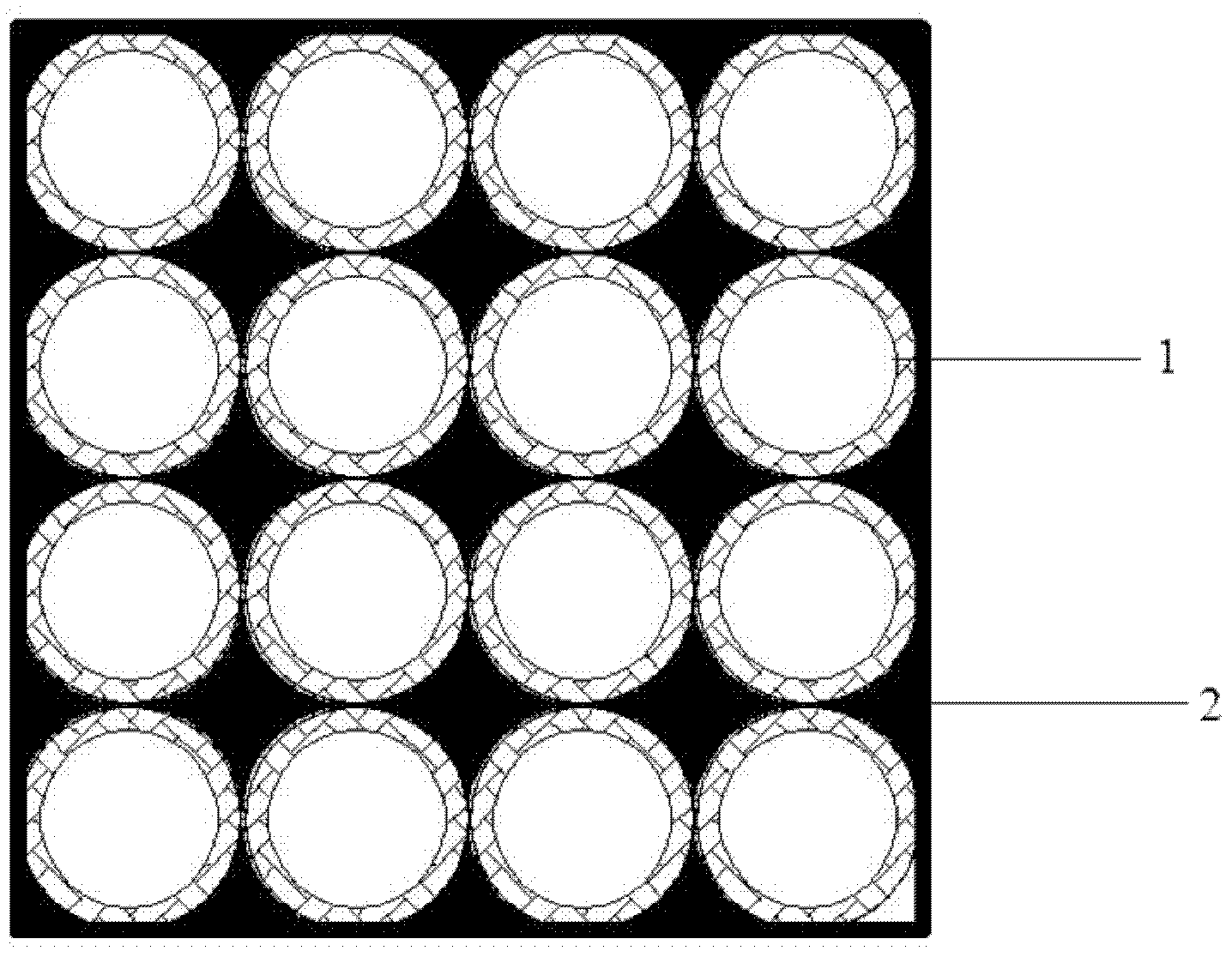

[0026] 1) Seal both ends of a stainless steel 304 alloy hollow tube 1 with an outer diameter of 1 mm, a wall thickness of 0.15 mm, and a length of 40 mm, and then pickle with HCl with a mass concentration of 1% to remove the oxide skin on the surface of the hollow tube 1 and impurities, then rinsed with deionized water, and dried for later use.

[0027] 2) The hollow tube 1 is vertically stacked in a circular copper mold with an inner diameter of 50 mm, and then the copper mold is placed in an electric arc melting furnace.

[0028] 3) Take Zr 55 Cu 30 Al 10 Ni 5 The amorphous alloy is placed in a quartz crucible with a nozzle above the copper mold in the electric arc melting furnace. Under the protection of an argon atmosphere, the amorphous alloy is heated to 1300°C in the electric arc melting furnace to completely melt to obtain a melt; 55Kpa pressure, the melt is pressed between the hollow tube 1 and the hollow tube 1 in the copper mold and rapidly cooled and solidified...

Embodiment 2

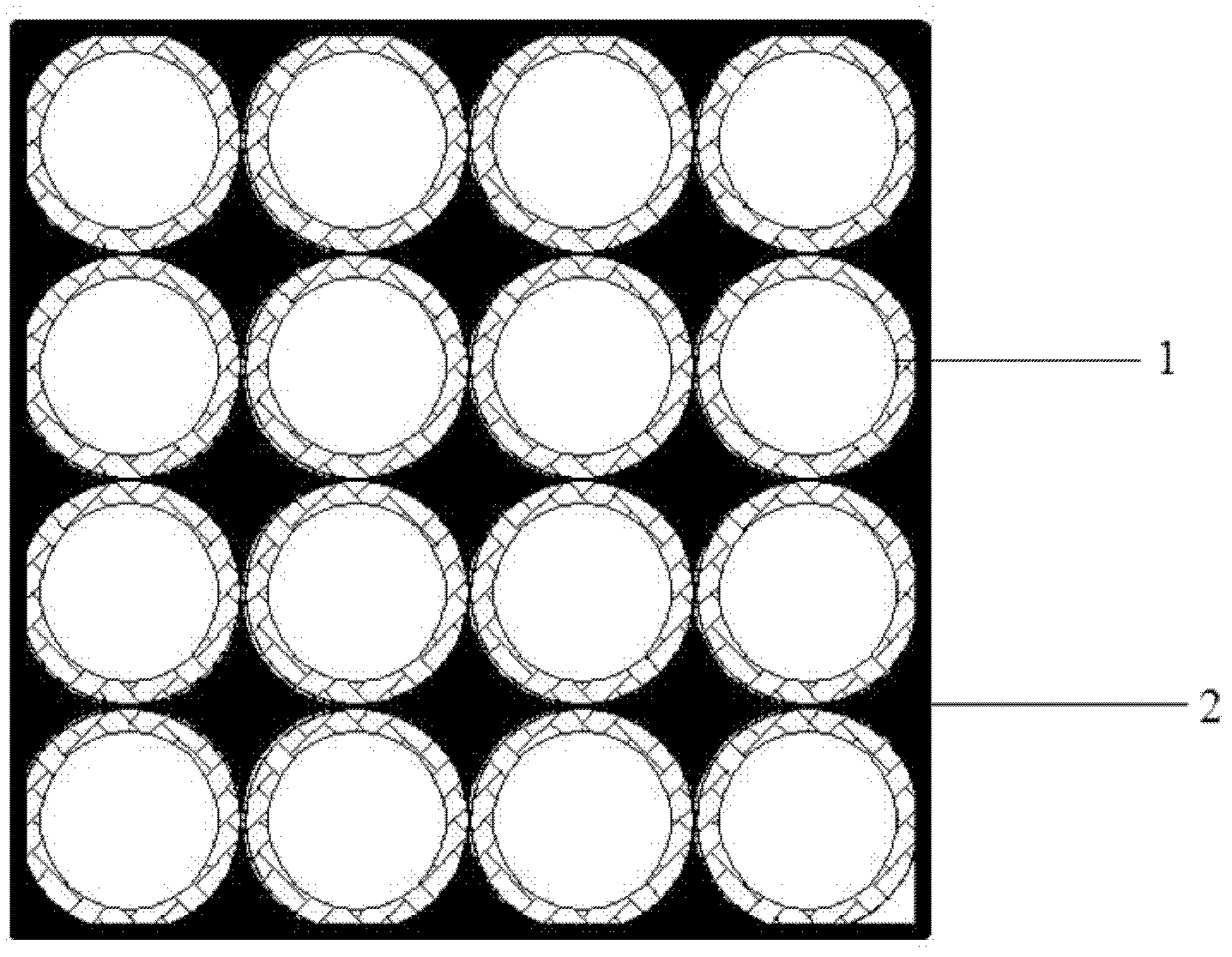

[0030] 1) Take a stainless steel 304 alloy hollow tube 1 with an outer diameter of 2 mm, a wall thickness of 0.1 mm, and a length of 40 mm and seal both ends, and then pickle with HCl with a mass concentration of 1% to remove the oxide skin on the surface of the hollow tube 1 and impurities, then rinsed with deionized water, and dried for later use.

[0031] 2) The hollow tube 1 is vertically stacked in a circular copper mold with an inner diameter of 50mm, and then the copper mold is placed in an electric arc melting furnace.

[0032] 3) The alloy powder is weighed, and the total mass of the alloy powder is 100%, wherein the mass fraction of the Zr powder is 50%, the mass fraction of the Cu powder is 25%, the mass fraction of the Al powder is 9%, the mass fraction of the Ni powder The mass fraction of the alloy powder is 16%. The alloy powder is placed in a quartz crucible with a nozzle above the copper mold in an electric arc melting furnace. Under the protection of an argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com