Device and method for ultrafast laser processing of micro inverted cone hole

An ultra-fast laser and inverted taper hole technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of destroying hole shape accuracy, affecting hole shape accuracy, poor surface quality, etc., to meet high-precision requirements. requirements, saving production costs, reducing the effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

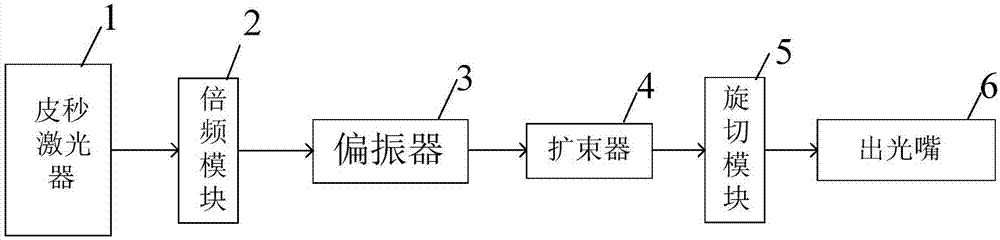

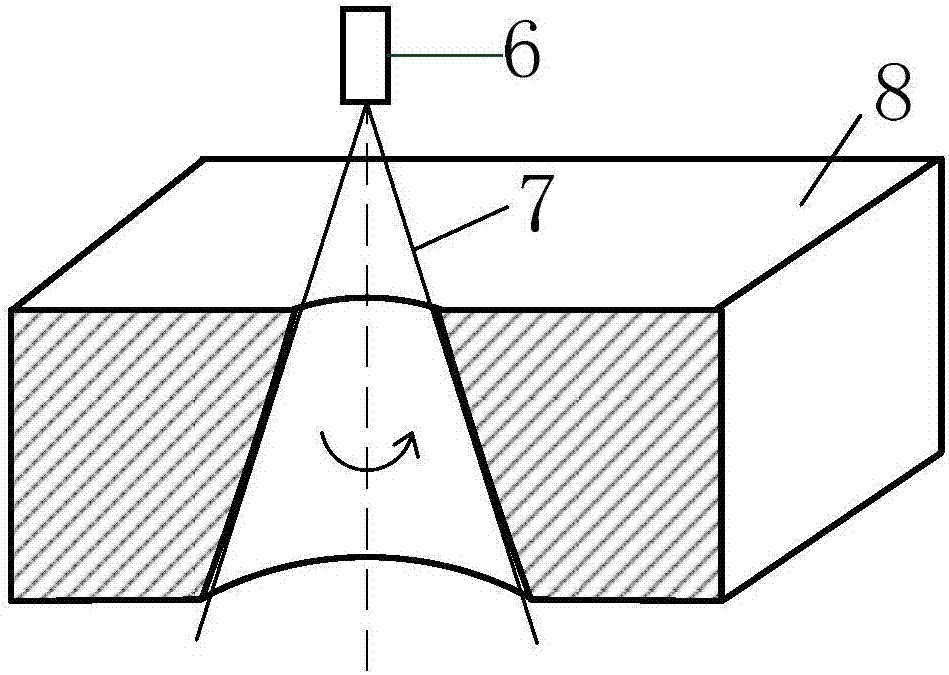

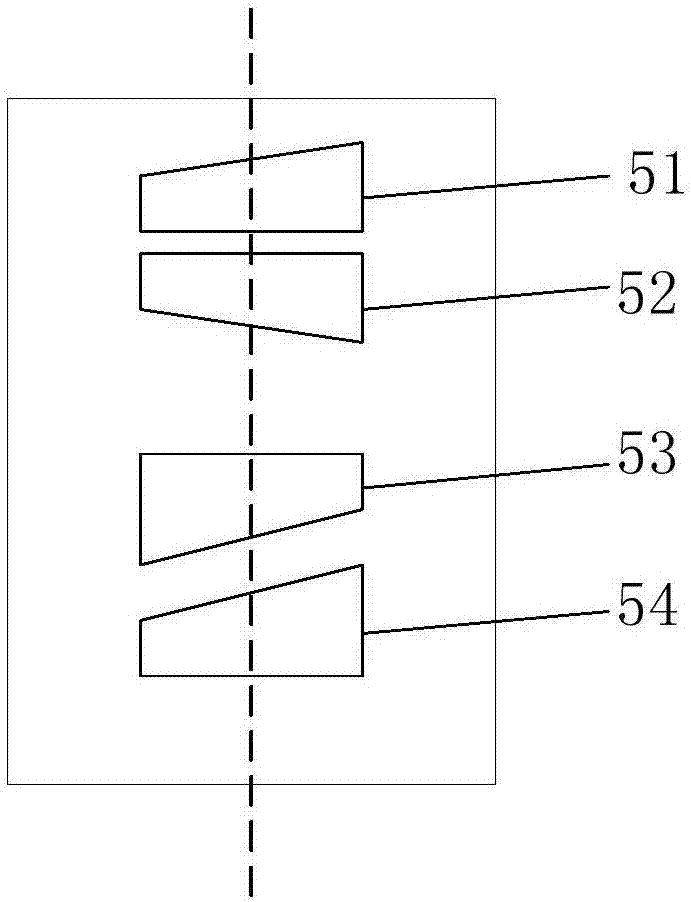

[0022] like figure 1 As shown, the device for ultrafast laser machining of micro-inverted taper holes includes a laser transmission module and an optical processing module. The laser transmission module includes a picosecond laser 1, a frequency doubling module 2, and a polarizer 3 arranged in sequence along the transmission direction of the optical path. And the beam expander 4, the optical processing module includes a rotary cutting module 5 and a light exit nozzle 6 arranged in sequence along the transmission direction of the optical path, and the output end of the beam expander 4 is connected to the rotary cutting module 5.

[0023] Among them, picosecond laser 1 is a solid-state picosecond laser with a wavelength of 1030nm, which has a high repetition rate and average power, especially when it int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com