Sol-gel coating comprising a fluorinated filler and culinary article equipped with such a coating

A sol, coating technology, applied in metal material coating process, coating, kitchen utensils and other directions, can solve problems such as difficulty in wetting PTFE powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Example 1: Sol-gel coating with fluorinated fillers

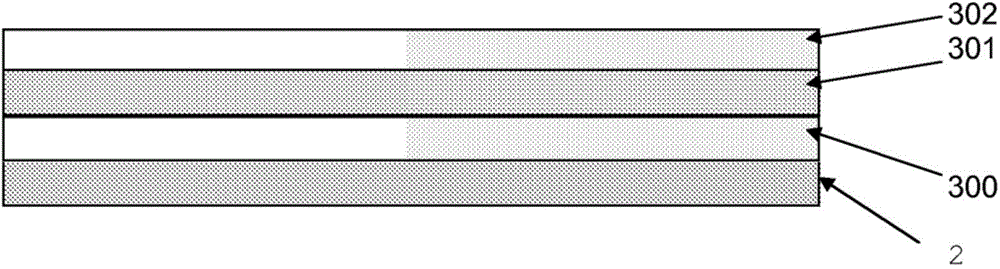

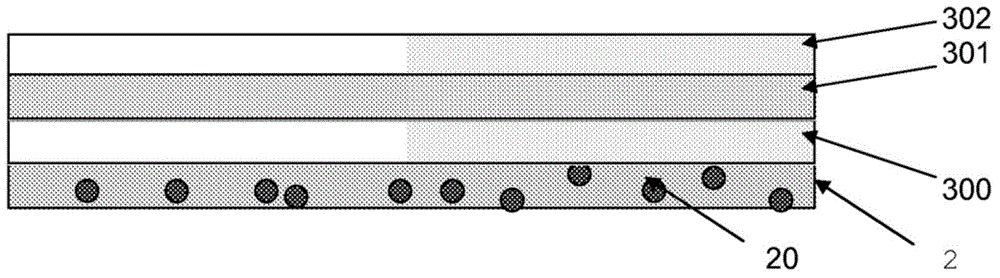

[0094] The sol-gel composition 2, the different components and their respective amounts are shown in Table 1 below, was sprayed onto the outside of the previously degreased and sandblasted multilayer support. An uncured 2 sol-gel coating was obtained.

[0095] Table 1: Chemical composition of sol-gel composition 2

[0096] components

Mass percentage (%)

"Filtered" sol-gel compositions

30-50%

30-50%

Butylene glycol (wetting agent)

0-10%

Pigment filler

0-10%

Fluorinated filler

≤10%

[0097] A "filtered" sol-gel composition is obtained as follows:

[0098] o starting from a metal alkoxide type precursor based initial sol-gel composition as defined above (preferably MTES and TEOS);

[0099] o This metal alkoxide is then hydrolyzed in a reactor in the presence of water and an acid or base catalyst (preferably an a...

Embodiment 3

[0114] Example 3: Scratch Resistance and Hydrophobicity / Wettability Test Results

[0115] The coated carrier of embodiment 1 and 2 (respectively in figure 2 and 3 indicated) were subjected to the hydrophobicity and scratch resistance tests indicated earlier in this application.

[0116] Based on the results obtained from these various tests with image 3 and 4 show.

[0117] These figures show that the presence of fluorinated fillers in the sol-gel coating can significantly improve the physicochemical properties of the sol-gel coating in terms of hydrophobicity and scratch resistance.

[0118] In particular, the results obtained from the hydrophobicity tests show a change in the behavior of the sol-gel coating, which is due to the presence of fluorinated fillers according to the invention. In fact, when no fluorinated fillers were present, the measured contact angle was 48.6°, while increasing the presence of CERAFLOUR in the coating resulted in a marked increase in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com