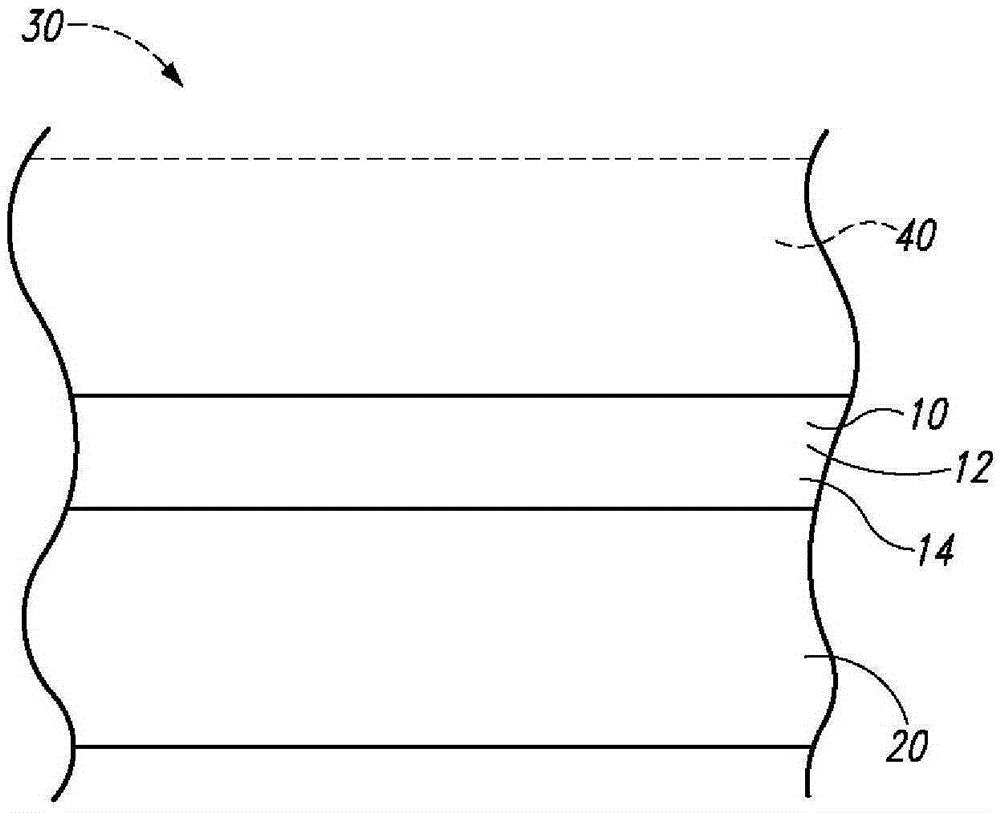

Corrosion-inhibiting sol-gel coating systems and methods

A corrosion-inhibiting, sol-based technology, applied in the direction of anti-corrosion coatings, coatings, liquid chemical plating, etc., can solve problems such as unobtrusive development, complicating the threat of corrosion, and loss of sealant integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

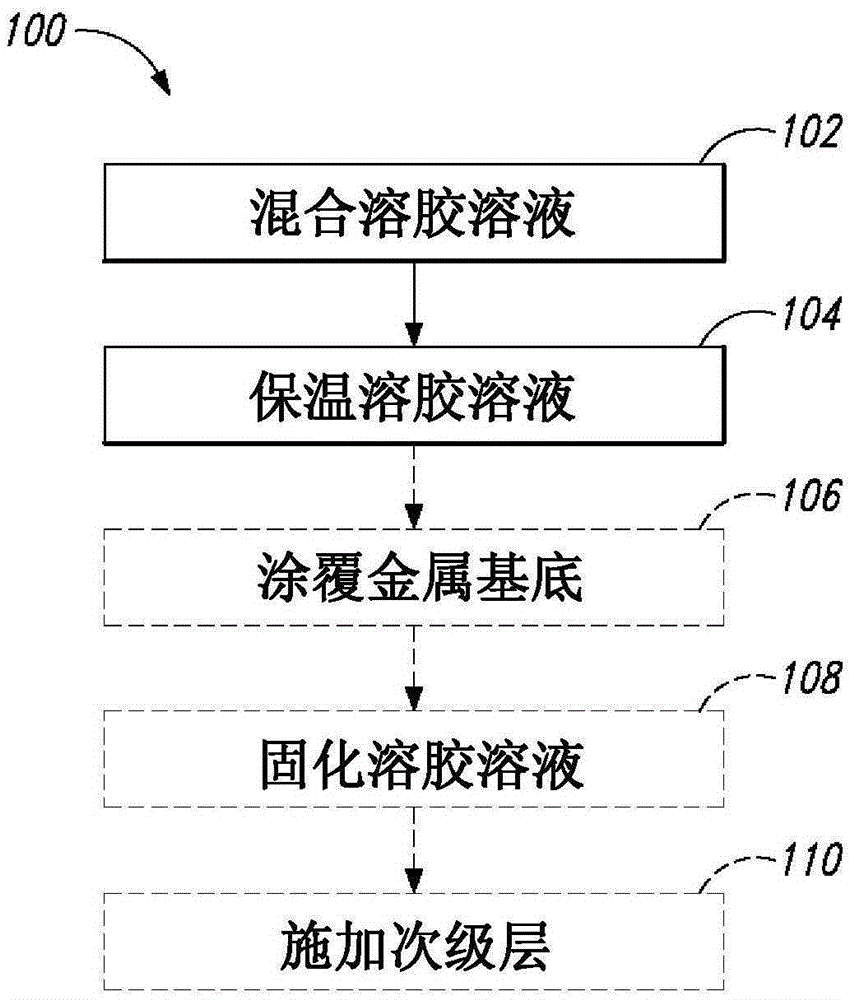

Method used

Image

Examples

Embodiment 1

[0051] The disulfide corrosion inhibitor 5,5-dithiobis-(1,3,4-thiadiazole-2(3H)-thione) (as 829 commercially available from Vanderbilt Chemicals, LLC) was dissolved in THF and then added to a sol solution of zirconium tetrapropanolate (also known as zirconium tetra-n-propoxide) to produce % concentration of mixed sol solutions of disulfide corrosion inhibitors. Sol solution is a commercial product 3M TM Surface Pretreatment AC-131. 3M TM Surface Pretreatment AC-131 is a silicon-zirconium based sol solution comprising a mixture of about 2% organosilane and about 1% zirconium alkoxide.

[0052] Four 2024-T3 aluminum alloy panels were coated with ScotchBrite TM Pad sanding. One panel was chromium conversion coated to serve as a positive control (known corrosion resistance). One board sprayed with 3M TM The surface was pretreated with AC-131 to serve as a negative control (known corrosion sensitivity). The other two panels were sprayed with mixed sol solutions to form a 0....

Embodiment 2

[0054] The disulfide corrosion inhibitor 5,5-dithiobis-(1,3,4-thiadiazole-2(3H)-thione)( 829) was dissolved in THF and then added to 3M TM Surfaces were pretreated in AC-131 to produce disulfide corrosion inhibitors at concentrations of 3% and 6%. At the 6% corrosion inhibitor concentration, all disulfide corrosion inhibitors did not dissolve, so only the 3% corrosion inhibitor concentration was further evaluated. Aluminum alloy panels were prepared and tested as in Example 1. Panels were inspected after 24 hours of neutral salt spray exposure. 3% of the samples exhibited superior corrosion protection compared to the negative control, where almost no pitting was observed. The negative control had a corrosion rating of 0; 3% of the samples had a corrosion rating of about 9 (ASTM1654-08, procedure B). A separately prepared 3% of the samples were subjected to the wet tape test for paint adhesion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com