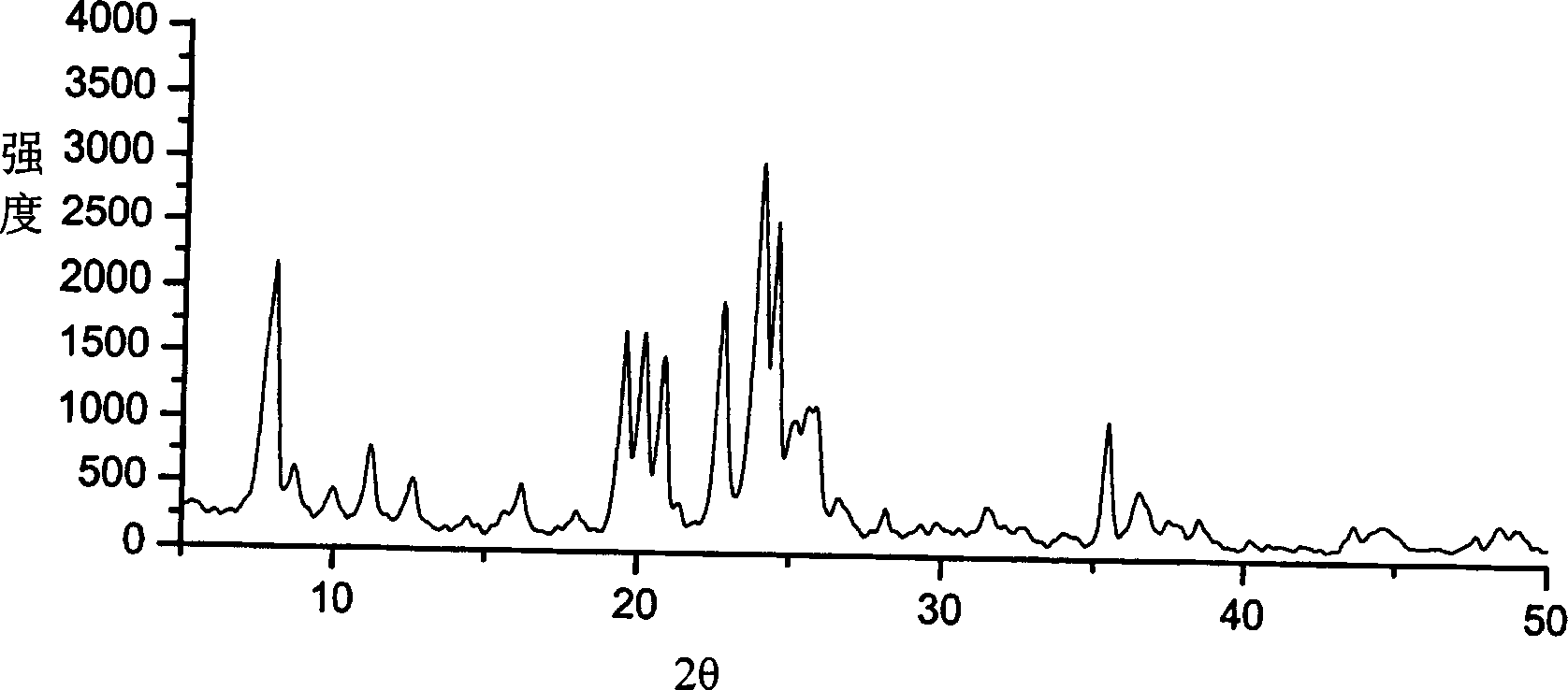

ZSM-22/ZSM-23 composite molecular screen and its preparation method

A composite molecular sieve, ZSM-23 technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve problems such as ineffectiveness, and achieve the effects of low pour point, high viscosity index and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 15.4 grams of sodium hydroxide was dissolved in 745 grams of water, 193.8 grams of silica sol (30% silicon dioxide) was added thereto, stirred for 2 hours, 15.0 grams of sodium ZSM-22 molecular sieve was added, and A was obtained after uniform stirring. 38.3 grams of pyrrolidine was added to the solution of 5.9 grams of aluminum sulfate and 244 grams of water, and B was obtained after stirring. Add B to A, stir vigorously for 24 hours, adjust the acidity and alkalinity of the system with 15.1 g of 98% concentrated sulfuric acid, and then continue vigorously stirring for 12 hours to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 =109, R / SiO 2 =0.56,OH - / SiO2 =0.08, Na / SiO 2 =0.4,H 2 O / SiO 2 =65, the addition of ZSM-22 molecular sieve is 0.26 of the silica weight. Transfer the initial colloid to a 2000 ml autoclave, seal it, adjust the stirring speed to 300 rpm, start to raise the temperature, raise the temperature to...

Embodiment 2

[0036] Dissolve 15.4 grams of sodium hydroxide in 571 grams of water, add 193.8 grams of silica sol (30% silicon dioxide) therein, stir for 2 hours, add 15.0 grams of sodium ZSM-22 molecular sieve, and obtain A after stirring evenly. 42 grams of isobutane was added to the solution of 5.9 grams of aluminum sulfate and 244 grams of water, and B was obtained after stirring. Add B to A, stir vigorously for 24 hours, adjust the acidity and alkalinity of the system with 15.1 g of 98% concentrated sulfuric acid, and then continue vigorously stirring for 12 hours to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 =109, R / SiO 2 =0.56,OH - / SiO 2 =0.08, Na / SiO 2 =0.4,H 2 O / SiO 2 =55, the addition of ZSM-22 molecular sieve is 0.26 of the silica weight. Transfer the initial colloid to a 2000 ml autoclave, seal it, adjust the stirring speed to 300 rpm, start to raise the temperature, raise the temperature to 175°C in 4 hours, and hydrot...

Embodiment 3

[0038] Dissolve 15.4 grams of sodium hydroxide in 571 grams of water, add 193.8 grams of silica sol (30% silicon dioxide) therein, stir for 2 hours, add 15.0 grams of sodium ZSM-22 molecular sieve, and obtain A after stirring evenly. 44 grams of isopropylamine are added to the solution of 1.5 grams of aluminum sulfate and 244 grams of water, and B is obtained after stirring. Add B to A, stir vigorously for 24 hours, adjust the acidity and alkalinity of the system with 15.1 g of 98% concentrated sulfuric acid, and then continue vigorously stirring for 12 hours to obtain the initial colloid. The molar composition of the initial colloid is: SiO 2 / Al 2 o 3 =300, R / SiO 2 =0.56,OH - / SiO 2 =0.08, Na / SiO 2 =0.4,H 2 O / SiO 2 =55, the addition of ZSM-22 molecular sieve is 0.26 of the silica weight. Transfer the initial colloid to a 2000 ml autoclave, seal it, adjust the stirring speed to 300 rpm, start to raise the temperature, raise the temperature to 175°C in 4 hours, and hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com