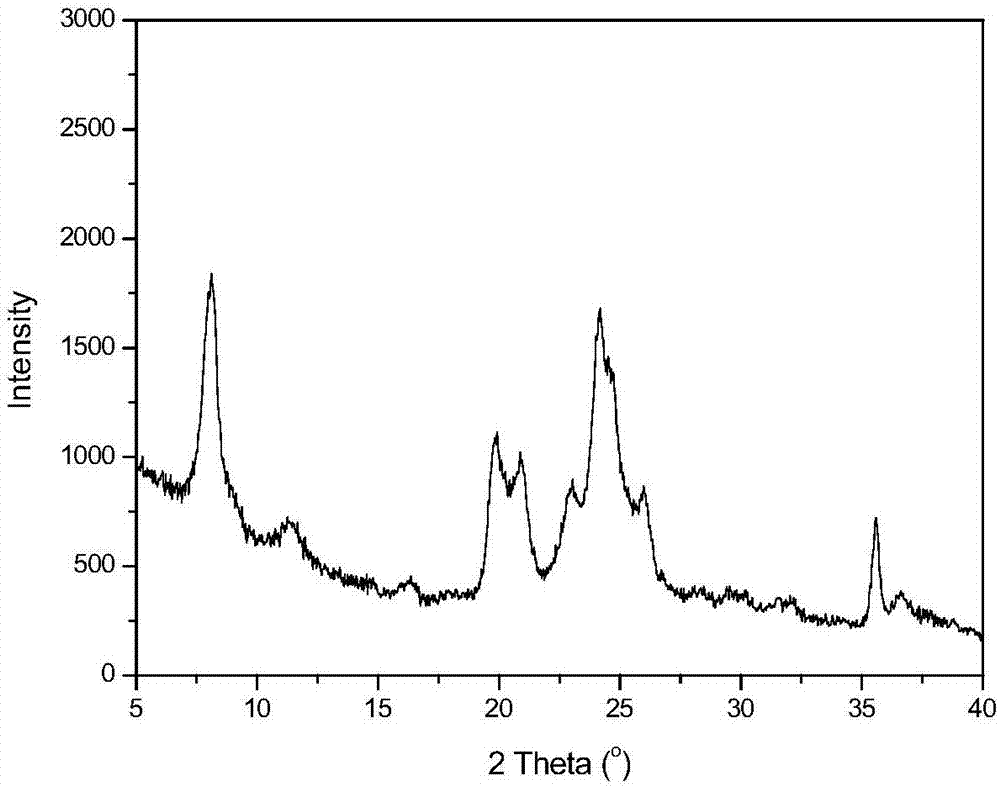

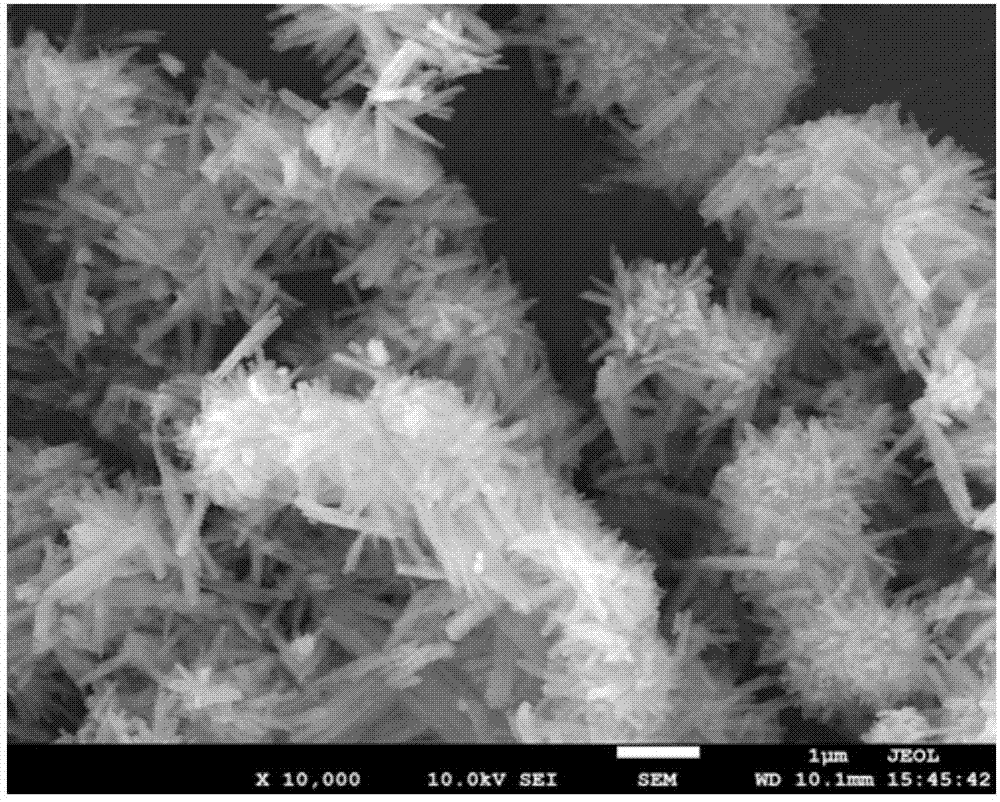

Zeolite molecular sieve containing TON/MTT skeleton topology structure and preparation method of zeolite molecular sieve

A technology of zeolite molecular sieve and topology structure, applied in the direction of molecular sieve catalyst, crystalline aluminosilicate zeolite, molecular sieve and alkali exchange compound, etc., can solve the problems of low catalyst yield, poor adaptability of molecular sieve, difficult relative content, etc., and achieve uniform particle size , excellent catalytic performance, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

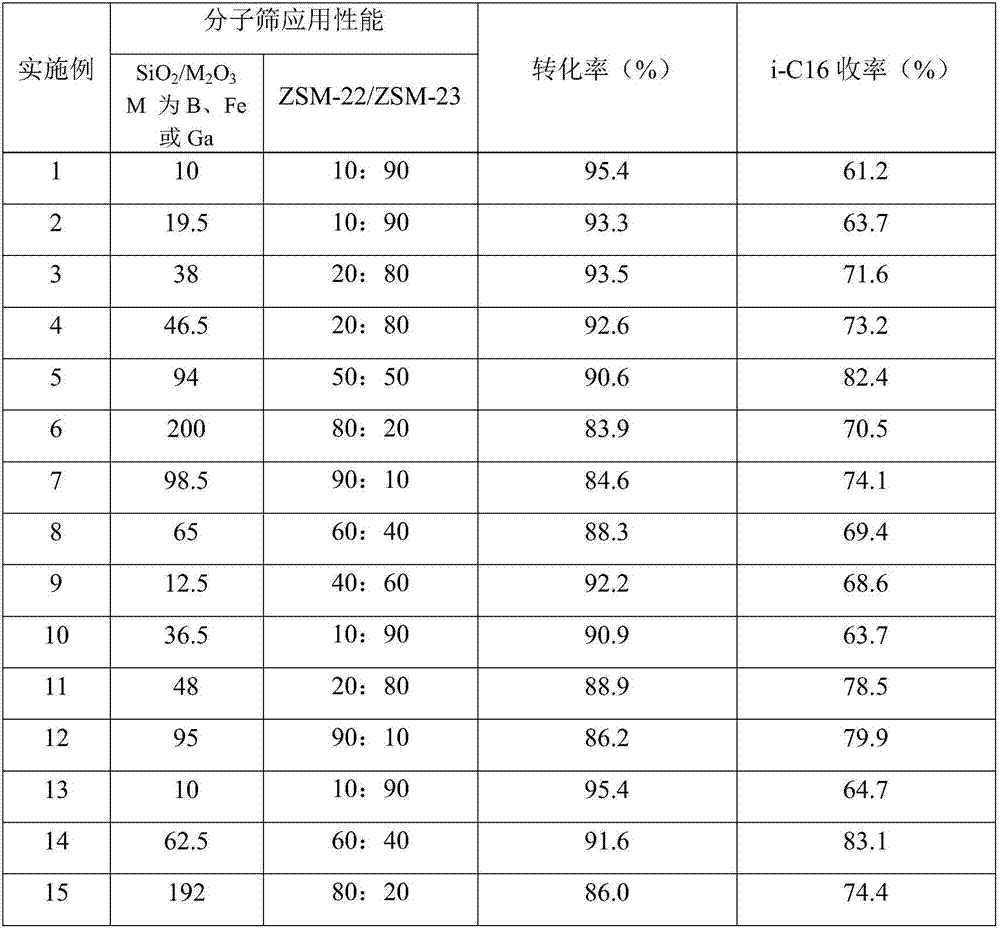

Examples

Embodiment 1

[0029] Add potassium hydroxide to deionized water, stir to completely dissolve, add ethylmethylamine and sodium borate successively, continue stirring until the mixture is completely dissolved, add dimethylamine and silica sol in order to form an initial gel with the following molar ratio Mixture (silicon source with SiO 2 Calculated, boron source is B 2 O 3 Based on OH - Count), SiO 2 : B 2 O 3 : Ethylmethylamine: Dimethylamine: OH - : Deionized water = 1:0.1:0.05:5.0:0.005:10.0; add all-silicon ZSM-22 as a seed crystal to the initial gel mixture obtained, and the addition amount is the silicon source (with SiO 2 Calculate) 1wt.%, and placed in an ultrasonic device, at 25 ℃, ultrasonic frequency 40kHz, ultrasonic power 100W, ultrasonic vibration for 180 minutes; the mixture obtained after ultrasonic is placed in a high-pressure microwave with PTFE lining In the reactor, use microwave radiation (microwave radiation frequency is 900MHz) to heat to 140℃, and crystallize under autog...

Embodiment 2

[0031] Add potassium hydroxide to deionized water, stir to dissolve completely, add diethylamine, potassium borate successively, continue to stir until the mixture is completely dissolved, add dimethylformamide, n-propylamine and silicone gel in order to form a mole Proportioning initial gel mixture (silicon source with SiO 2 Calculated, boron source is B 2 O 3 Based on OH - Count), SiO 2 : B 2 O 3 :Diethylamine: dimethylformamide + n-propylamine: OH - : Deionized water=1:0.05:0.1:4.0 (dimethylformamide:n-propylamine=3:1, molar ratio):0.01:30.0; add all-silicon ZSM-22 to the resulting initial gel mixture as crystal Species, the addition amount is the added silicon source (with SiO 2 Calculate) 2wt.%, and placed in an ultrasonic device, at 25 ℃, ultrasonic frequency 40kHz, ultrasonic power 100W conditions for ultrasonic oscillation for 180 minutes; the mixture obtained after ultrasound is placed in a high-pressure microwave with a polytetrafluoroethylene lining In the reactor, us...

Embodiment 3

[0033] Add potassium hydroxide to deionized water, stir to dissolve completely, add 1,6-hexamethylene diamine, boric acid successively, continue stirring until the mixture is completely dissolved, add isopropylamine, methyl orthosilicate and ethyl orthosilicate in order , The initial gel mixture (silicon source with SiO 2 Calculated, boron source is B 2 O 3 Based on OH - Count), SiO 2 : B 2 O 3 :1,6-Hexanediamine: Isopropylamine: OH - : Deionized water = 1 (methyl orthosilicate: ethyl orthosilicate = 1:4, molar ratio, based on SiO 2 Calculate): 0.025: 0.2: 3.0: 0.02: 20.0; add all-silicon ZSM-22 as a seed crystal to the initial gel mixture obtained, and the addition amount is the silicon source (with SiO 2 Calculate) 5wt.%, and placed in an ultrasonic device, at 30 ℃, ultrasonic frequency 50kHz, ultrasonic power 500W, ultrasonic oscillation for 120 minutes; the mixture obtained after ultrasonic is placed in a high-pressure microwave with a polytetrafluoroethylene lining In the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com