Hydrodenitrogenation catalyst capable of removing nitrogen-containing compound from coal tar, and preparation method and application thereof

A nitrogen compound, hydrogenation and denitrogenation technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of lack of cleanliness, large-scale utilization technology, pollution, waste of resources, etc., to achieve good results Hydrodesulfurization performance, good water resistance, good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

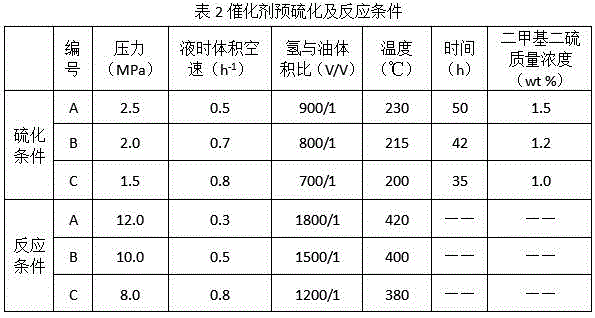

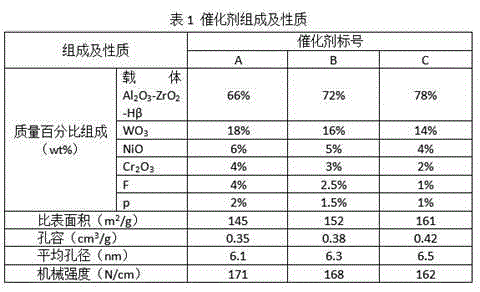

Embodiment 1

[0022] A hydrodenitrogenation catalyst capable of removing nitrogen-containing compounds from coal tar is composed of an active component, an additive and a carrier, and the active component is composed of tungsten trioxide, nickel monoxide and chromium trioxide, and the content of the tungsten trioxide is 15wt% of the catalyzer, the nickel monoxide content is 5wt% of the catalyzer, and the dichromium trioxide content is 3.5wt% of the catalyzer; the auxiliary agent is fluorine and phosphorus, and in elemental calculation, the fluorine content is 3.2wt% of the catalyzer, so Described phosphorus content is 1.6wt% of catalyzer; Carrier is made up of aluminum oxide, zirconium oxide, Hβ molecular sieve, binding agent and extrusion aid, calculates on a dry basis, and described carrier content is 73wt% of catalyzer, and described alumina, The weight ratio of zirconia and Hβ molecular sieve is 15.8:1.6:2.2, the weight of the binder is 5% of the weight of the alumina, and the content of...

Embodiment 2

[0031] A hydrodenitrogenation catalyst capable of removing nitrogen-containing compounds from coal tar is composed of an active component, an additive and a carrier, and the active component is composed of tungsten trioxide, nickel monoxide and chromium trioxide, and the content of the tungsten trioxide is 17wt% of the catalyzer, the nickel monoxide content is 5wt% of the catalyzer, and the dichromium trioxide content is 2.5wt% of the catalyzer; the auxiliary agent is fluorine and phosphorus, and in elemental calculation, the fluorine content is 2.5wt% of the catalyzer, so Described phosphorus content is 1.5wt% of catalyzer; Carrier is made up of alumina, zirconium oxide, Hβ molecular sieve, binding agent and extrusion aid, calculates on dry basis, and described carrier content is 69wt% of catalyzer, and described alumina, The weight ratio of zirconia and Hβ molecular sieve is 16:1.5:2.5, the weight of the binder is 7% of the weight of the alumina, and the content of the extrus...

Embodiment 3

[0040] Weigh 1000 g of alumina precursor pseudoboehmite, 103 g of zirconia, 162 g of Hβ molecular sieve and NH 4 F 25 g and mix evenly, then add 100 g of pseudo-boehmite binder, 16 g of squash gum, 48 g of acetic acid, and 774 g of distilled water into the above mixture, knead in a kneader for 150 min, put Extrusion molding in strip machine. Then dry at 40 °C for 4 h, and then dry at 100 °C for 10 h, then raise the temperature to 650 °C at a heating rate of 1 °C / min, and roast for 8 h to obtain 1027 g of the finished carrier. Calculated on a dry basis, alumina accounts for 75% of the total weight of the carrier , zirconia accounts for 10% of the total weight of the carrier, and Hβ molecular sieve accounts for 15% of the total weight of the carrier.

[0041] Add 307 g of ammonium metatungstate, the precursor of tungsten trioxide, 343 g of nickel nitrate, the precursor of nickel monoxide, and 309 g of chromium nitrate, the precursor of chromium trioxide, into 575 g of distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com