A method for improving the yield of lignin pyrolysis oil and adjusting the composition of pyrolysis oil

A technology for lignin and pyrolysis oil, which is applied in the petroleum industry, processing hydrocarbon oil, preparation of liquid hydrocarbon mixture, etc. To achieve the effect of simple process, reduced content of condensed aromatic hydrocarbons and furans, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

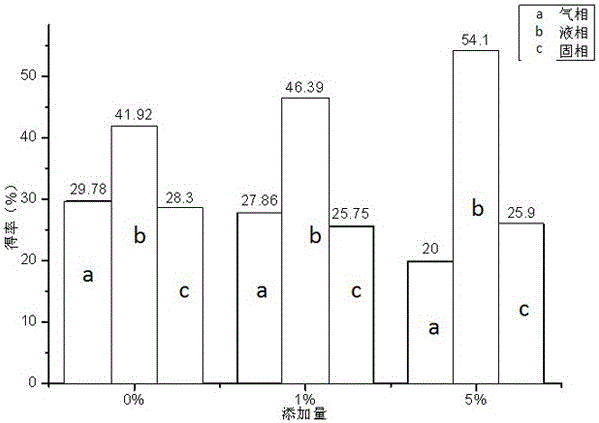

[0019] Weigh 1.0 g of moso bamboo EMAL lignin and pour it into a porcelain boat, and place the porcelain boat at one end of the quartz tube in the tube furnace. During the pyrolysis test, turn on the heating power, set the temperature of the furnace body to 600°C, and inject high-purity nitrogen (99.999%, flow rate 0.5L / min) for 30 minutes to blow out the air in the quartz tube. When heated to the preset temperature, after the temperature is constant, the porcelain boat containing the sample is quickly pushed to the center of the quartz tube in the tube furnace for pyrolysis reaction, and the reaction time is 2 minutes. The pyrolysis product was collected by cold trap trapping method, the high-purity nitrogen flow rate was adjusted to 1.2L / min, the volatile matter in the carrier gas was passed into the Monterey washing bottle placed in the ice-salt bath, and 500mL methanol was used as the Absorbs solvents. The non-condensable gas is quantitatively measured by the gas collecti...

Embodiment 2

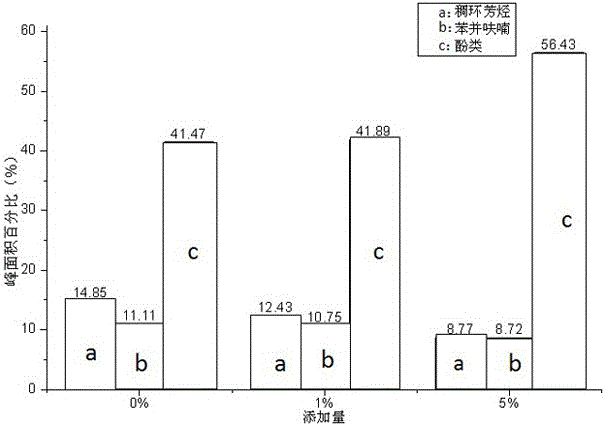

[0021] Weigh 1.0g of EMAL lignin from moso bamboo and place it in an agate mortar, add 0.01g of copper oxide powder, after grinding, pour the mixture into a porcelain boat, and the rest of the steps are the same as in Example 1. After analysis, the gas phase product yield was 27.86%, the solid phase product yield was 25.75%, and the liquid phase product yield was 46.39%. After the liquid phase product was analyzed by GC-MS, the peak area percentage of fused ring aromatics was 12.43%, the peak area percentage of benzofurans was 10.75%, and the peak area percentage of phenols was 41.89%.

Embodiment 3

[0023] Weigh 1.0g of EMAL lignin from moso bamboo and place it in an agate mortar, then add 0.05g of copper oxide powder, after grinding, pour the mixture into a porcelain boat, and the rest of the steps are the same as in Example 1. After analysis, the gas phase product yield was 20%, the solid phase product yield was 25.9%, and the liquid phase product yield was 54.1%. After the liquid phase product was analyzed by GC-MS, the peak area percentage of condensed ring aromatics was 8.77%, the peak area percentage of benzofurans was 8.72%, and the peak area percentage of phenols was 56.43%.

[0024] figure 1 For embodiment 1-3 pyrolysis product three component yield analysis, figure 2 For pyrolysis oil composition analysis.

[0025] From figure 1 It can be clearly seen that with the increase of copper oxide addition, the yield of liquid phase products in pyrolysis products increases significantly, while from figure 2 It can be seen that the content of fused ring aromatics a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com