Method for preparing mesoporous material with high hydrothermal stability by ZSM-5

A technology of mesoporous materials and thermal stability, applied in the direction of crystalline aluminosilicate zeolites, etc., can solve problems such as unsatisfactory long-range order, non-compliance with green chemistry, human and environmental toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

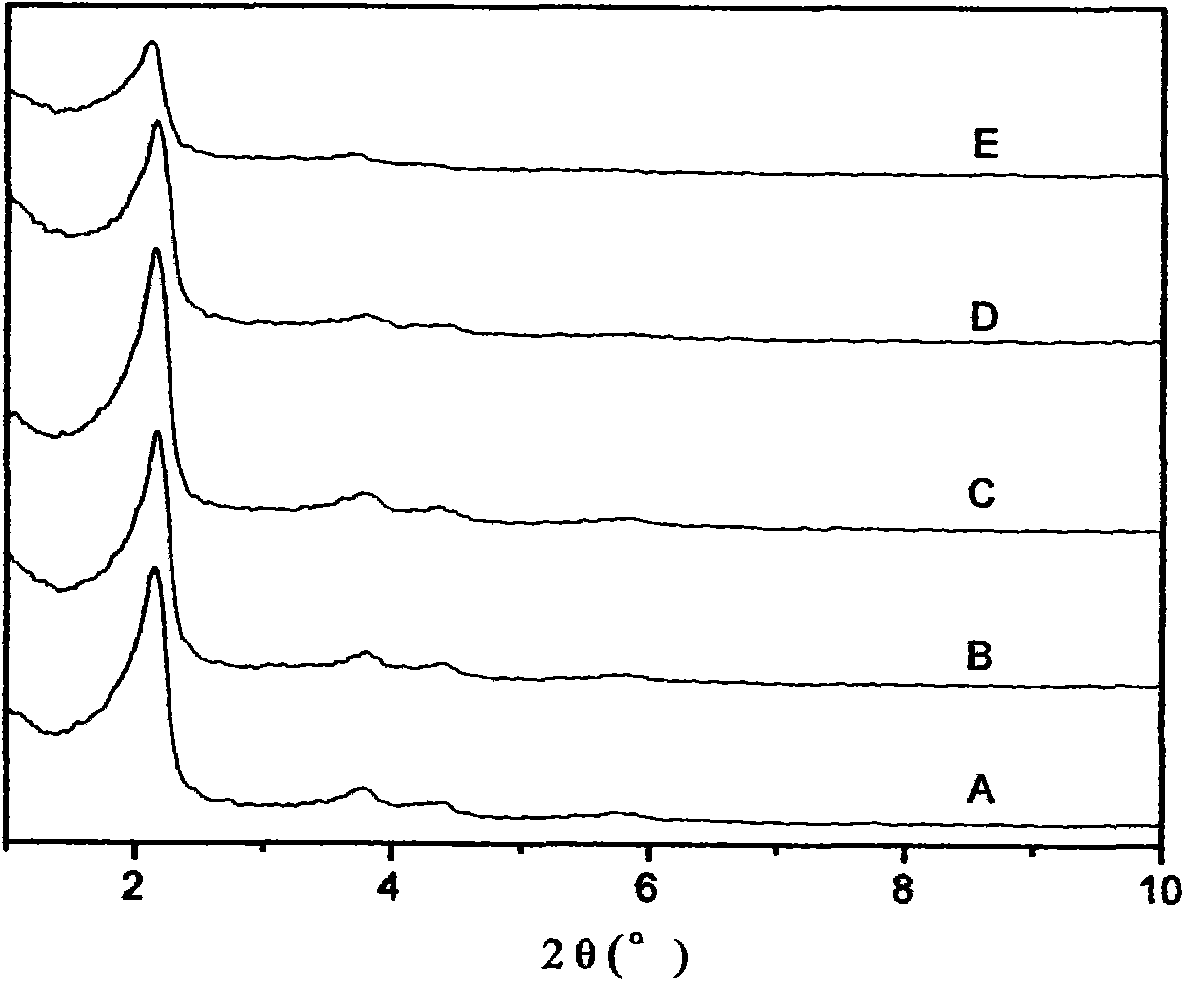

[0017] Proportion by mass ZSM-5(SiO 2 / Al 2 o 3 Molar ratio = 300): cetyltrimethylammonium bromide: NaOH: H 2 O=1:2.3:4:95 Mix the materials to obtain a suspension, then place the resulting suspension in an oil bath environment, stir at 100°C for 6 hours, cool to room temperature and adjust to pH=9, then stirred at room temperature for 24 hours, finally the X-ray diffraction pattern (XRD) of the sample obtained after washing and drying is shown in figure 1 a.

Embodiment 2-5

[0019] In Example 1, after the mixture was cooled to room temperature, it was adjusted to pH=8-5 with 2 mol / L hydrochloric acid aqueous solution, then stirred at room temperature for 24 hours, and finally washed and dried to obtain the target sample (see Table 1).

[0020] Table 1 Example 2-5

[0021]

[0022] figure 1 It shows that the samples obtained in the range of pH=9-5 all have diffraction peaks at low angles, indicating that the product has a mesoporous structure. However, the pH value has a certain influence on the product structure. When the pH=9-7, the obtained material all appears four diffraction peaks, and the sine square ratio of the diffraction angle is sin 2 θ 1 : sin 2 θ 2 : sin 2 θ 3 : sin 2 θ 4 =1:3:4:7, indicating that the sample structure conforms to the two-dimensional hexagonal model, and is a mesoporous material with high long-range order. This is the first report on the synthesis of mesoporous materials from microporous molecular sieve ZSM...

Embodiment 6

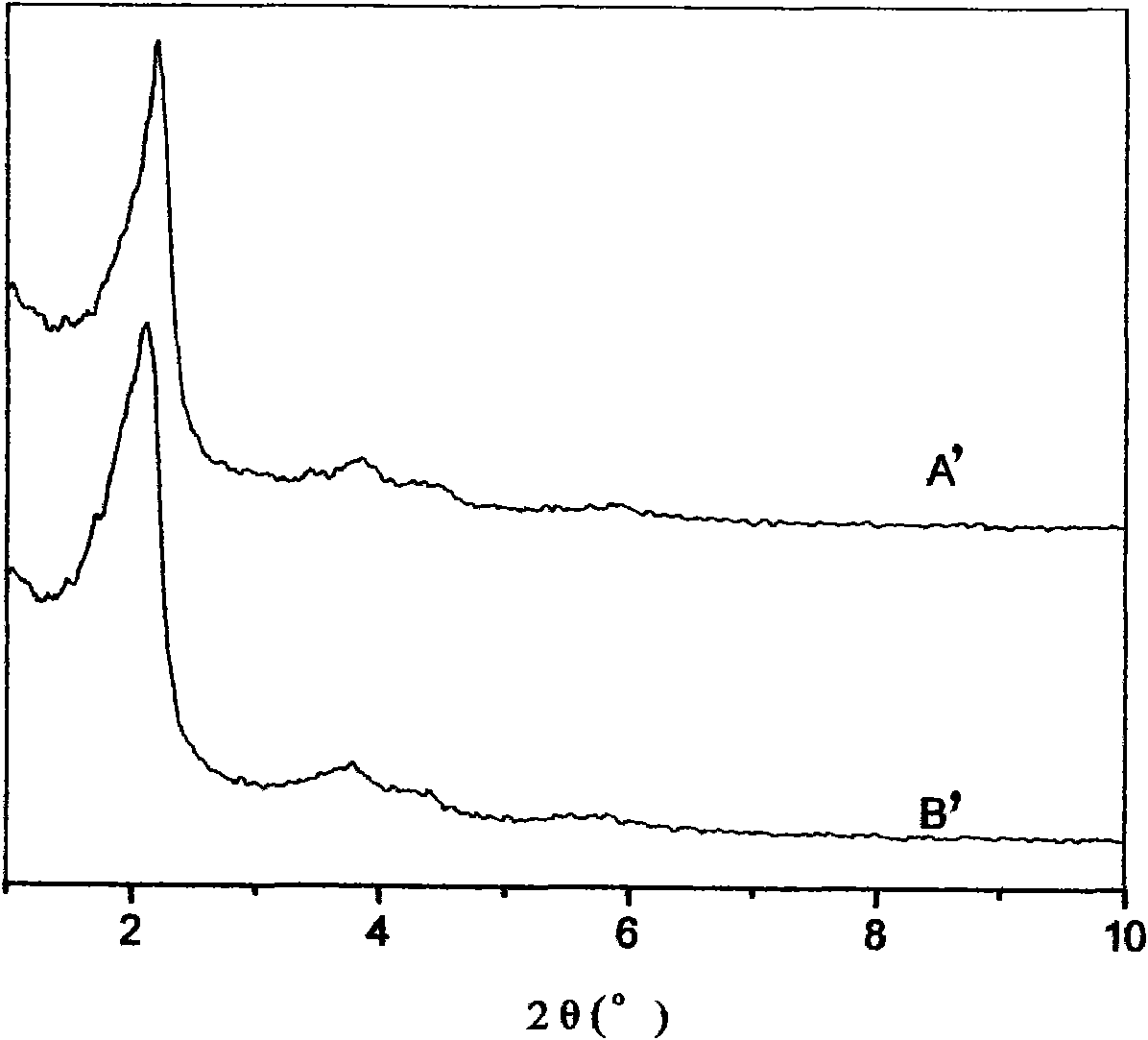

[0024] Proportion by mass ZSM-5(SiO 2 / Al 2 o 3 =50):tetradecyltrimethylammonium bromide:NaOH:H 2 O=1:2.3:4:95 Mix the materials to obtain a suspension, then place the obtained suspension in an oil bath environment, stir at 100°C for 6 hours, and adjust it with 2 mol / liter aqueous hydrochloric acid solution after cooling to room temperature. To pH=7, then stirred at room temperature for 12 hours, finally after washing and drying, the X-ray diffraction pattern (XRD) of the obtained sample is shown in figure 2 A'.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com