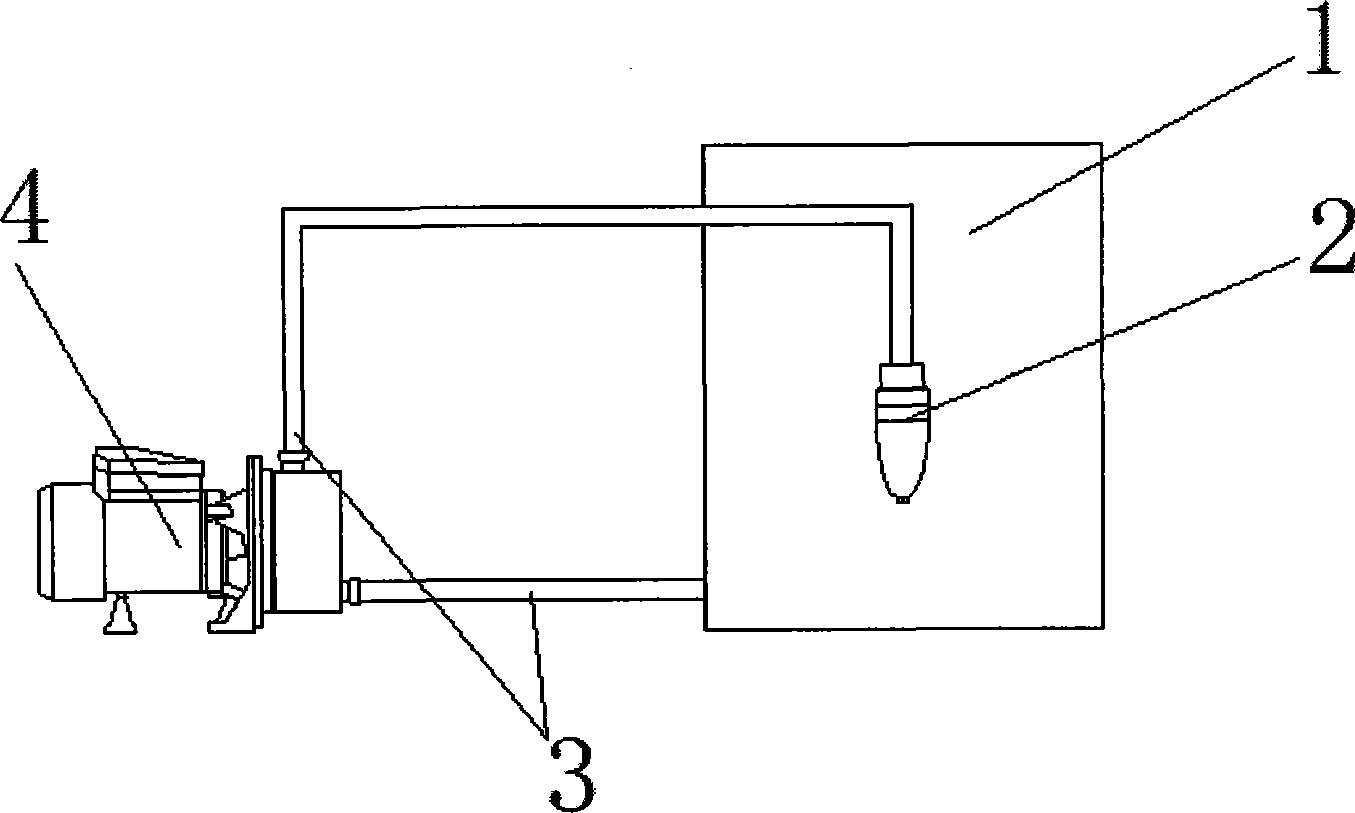

Novel swirl dispersing device

A dispersing device and swirl technology, which is applied in the field of swirl technology and new devices, can solve the problems of low processing capacity, rapid fall into the bottom of the tower or adhesion to the tower wall, and small airflow resistance, so as to avoid temperature and concentration fluctuations. Uniformity, avoiding the sinking of solid materials, and reducing the effect of liquid film resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The heat transfer effect comparison of gas swirl or not in embodiment 1 spray tower

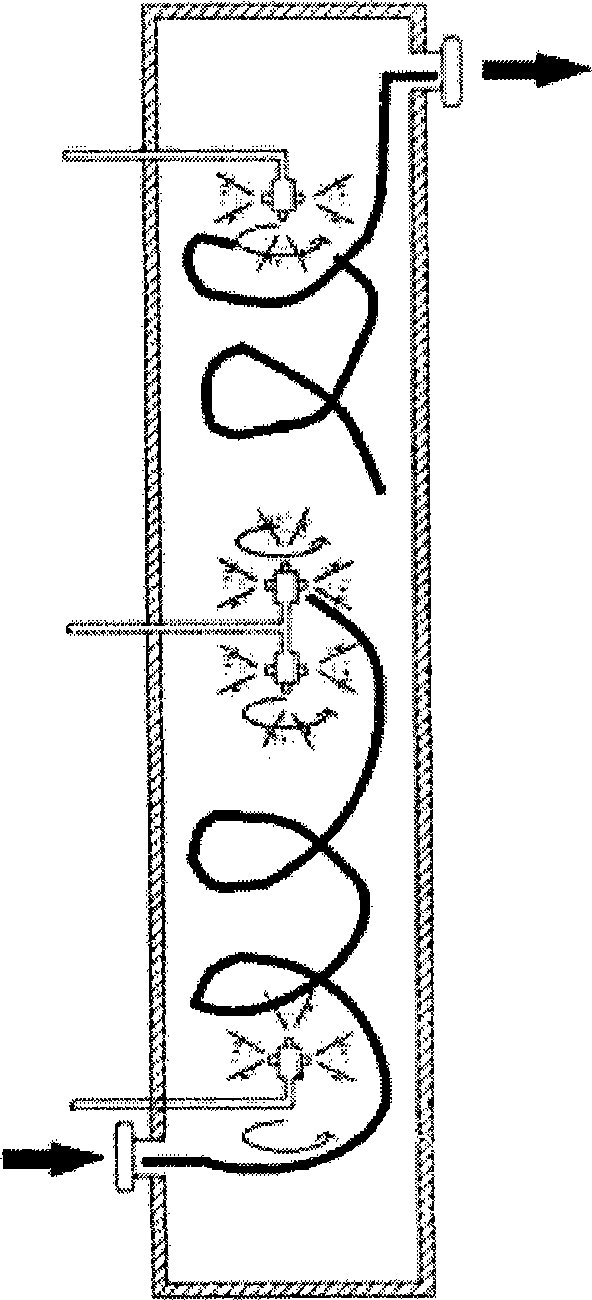

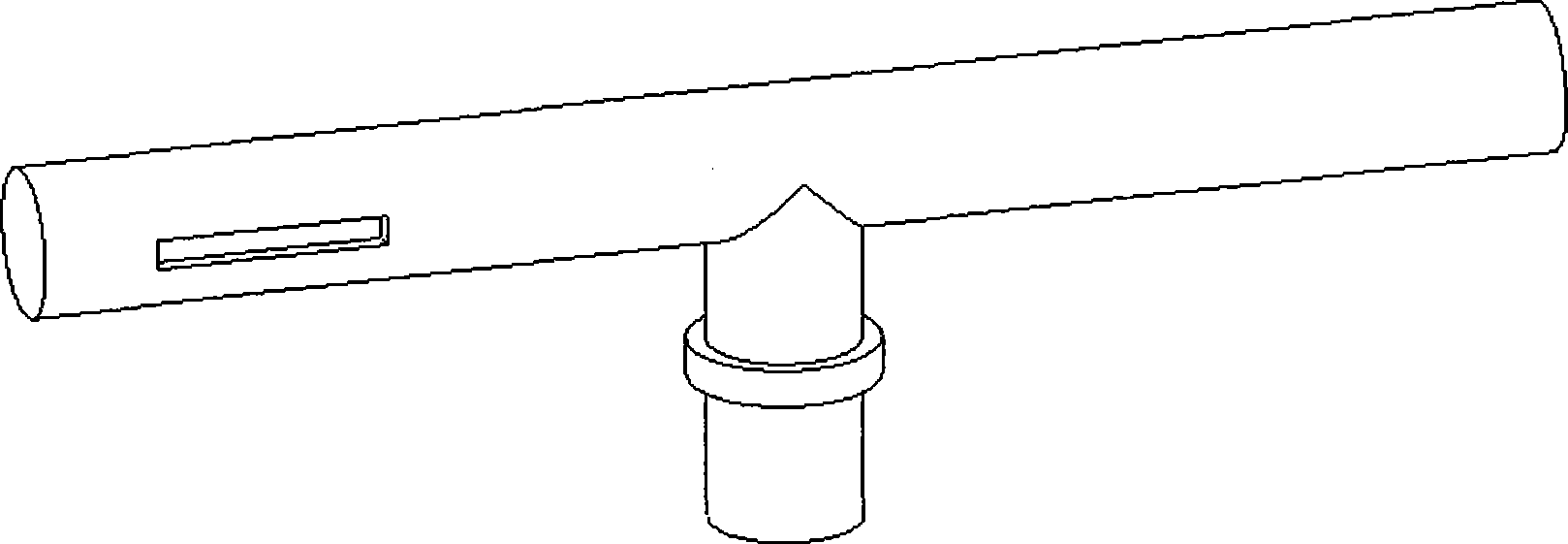

[0056] In a tower with a diameter of 300mm and a height of 1000mm, use hot water with a flow rate of 200L / h and 61°C to spray from the top of the tower, 60m 3 / h The air is ejected from opposite directions at both ends of the movable air duct at the bottom of the tower, and the reaction force of the gas causes the nozzle to rotate to form a gas swirl. For details of the simple swirl device, see Image 6 .

[0057] Use hot water of the same temperature to atomize and spray from the top of the tower, and through the temperature difference of the liquid collected at the top and bottom of the tower, the tendency of the surface of the atomized water droplets to vaporize into the gas phase can be judged, and the heat transfer effect can be evaluated.

[0058] Such as Figure 7 As shown, the temperature drop trend in the case of mixed cyclone flow is significantly greater than that in the c...

Embodiment 2

[0059] The mass transfer effect comparison of gas swirl in embodiment 2 spray tower

[0060] In a tower with a diameter of 300mm and a height of 1000mm, use 0.1% NaOH solution with a flow rate of 200L / h to spray from the top of the tower, CO 2 (2%)~The air mixture is sprayed from opposite directions at both ends of the movable air guide pipe at the bottom of the tower. The reaction force of the gas causes the nozzle to rotate and form a gas swirl. See Image 6 .

[0061] Use NaOH solution with the same concentration and the same initial conductance value to atomize and spray from the top of the tower, and measure the conductance value change of the liquid collected at the bottom of the tower, according to the CO with gas swirl and gas without swirl 2 (2%)~The change in the conductance value of the reaction between the air mixture and the alkali can judge whether the gas swirl is under the condition of liquid film control to improve the mass transfer effect.

[0062] as attac...

Embodiment 3

[0063] Embodiment 3 stirring performance effect evaluation

[0064] Put 500L of clean water in a container with a diameter of 1500mm and a height of 1000mm. The rotary nozzle is connected to the outlet pipe of the pump and placed in the solution. The inlet pipe of the pump is placed in the solution to allow material circulation. The pressure and flow of the pump can be changed. The rotation speed and the spraying distance of the rotating nozzle optimize the mixing effect. The mechanical stirrer in the comparative experiment was installed on the top of the container, and the three-blade propeller-type stirring paddle was placed in the same position in the solution through the stirring shaft.

[0065] By adding NaCl solution with the same solubility from the upper part or inside the nozzle in the same volume of water, and measuring the change trend of the conductance value and the equilibrium time at any point, the mixing effect under various comparison conditions can be well ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com