Tropsch synthesis method of fixed bed

A Fischer-Tropsch synthesis and fixed-bed technology, which is used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the production of hydrocarbons from carbon oxides. and other problems to achieve the effect of reducing reaction hot spots, improving mass transfer and heat transfer performance, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

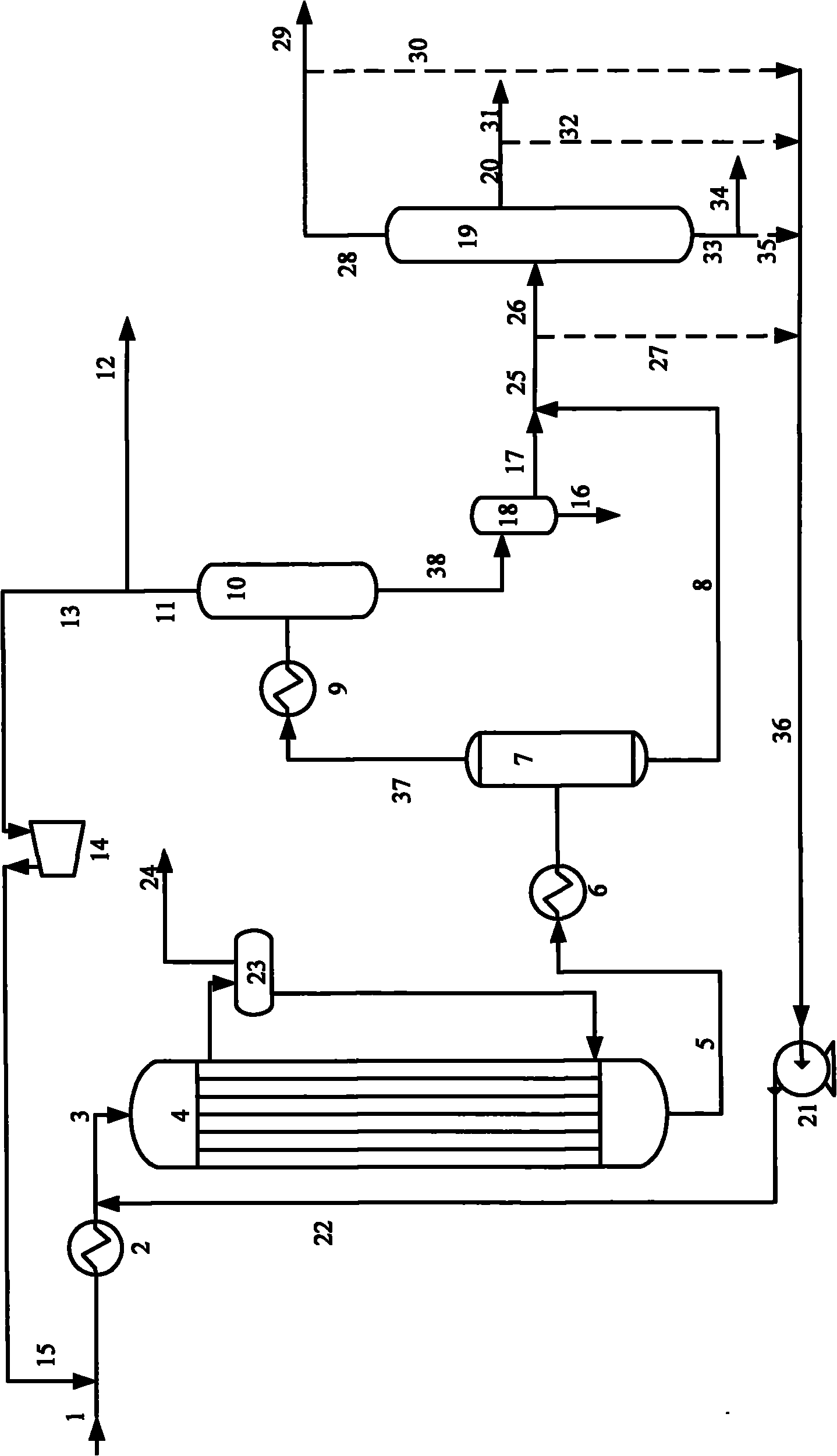

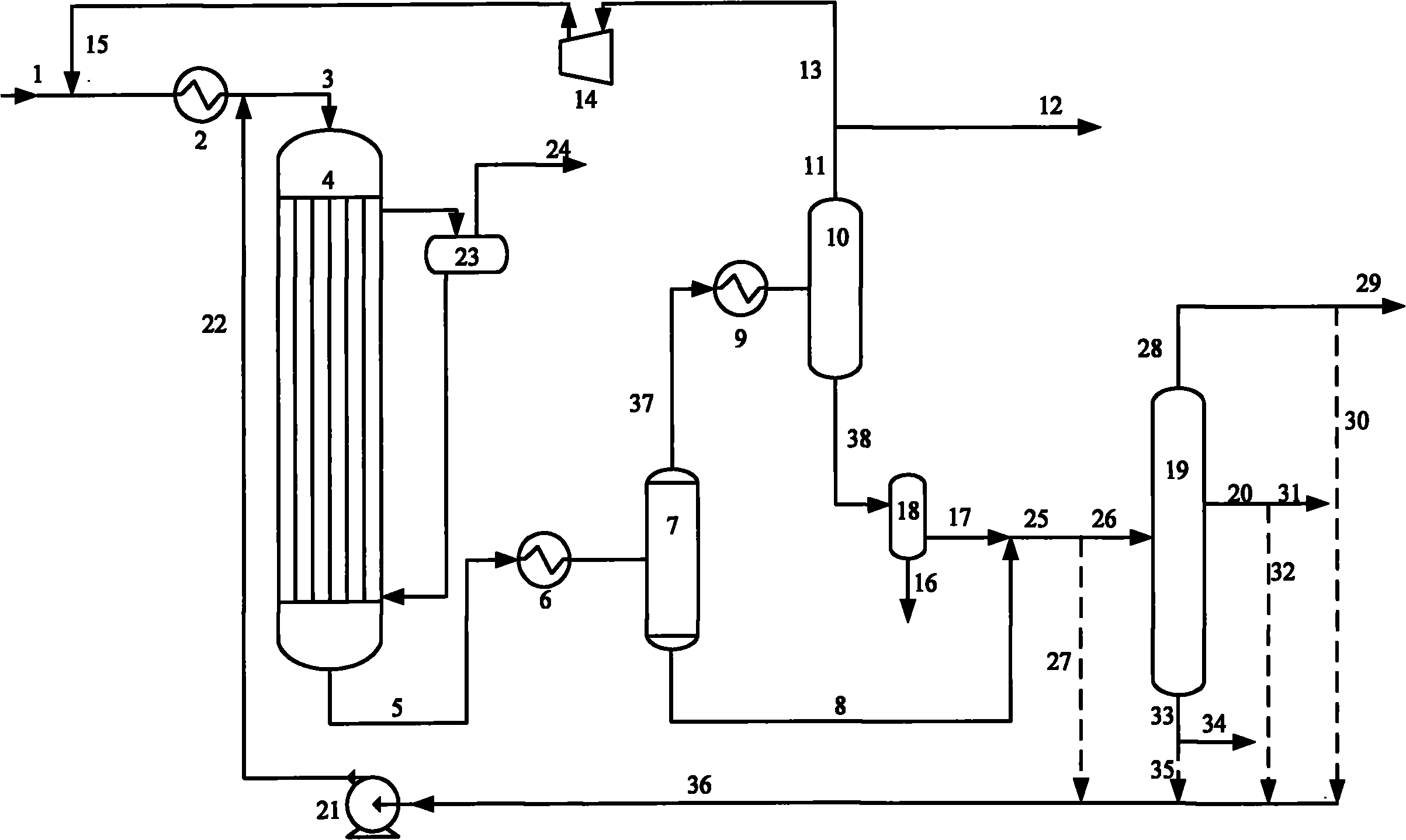

[0039] This embodiment adopts cobalt-based Fischer-Tropsch synthesis catalyst, figure 1 in the process flow. The catalyst adopts a conventional preparation method, and the solution containing cobalt nitrate is impregnated on the alumina carrier, and the catalyst is obtained after drying and roasting. The content of metal cobalt in the finished catalyst is 20%, and the addition amount of noble metal additive Pd is 0.1%. The catalyst is filled in each reaction tube, and the pressure drop of each reaction tube is as close as possible. Before the introduction of syngas, the catalyst needs to pass through H 2 Reduction, reduction reaction conditions: the pressure is 0.5MPa, and the reaction temperature is 400°C. After reduction, it is lowered to 150°C to introduce fresh raw material synthesis gas. H of purified raw syngas 2 The / CO ratio was 2.0.

[0040] The fresh raw material synthesis gas enters the fixed-bed Fischer-Tropsch synthesis reactor, and carries out the Fischer-T...

Embodiment 2

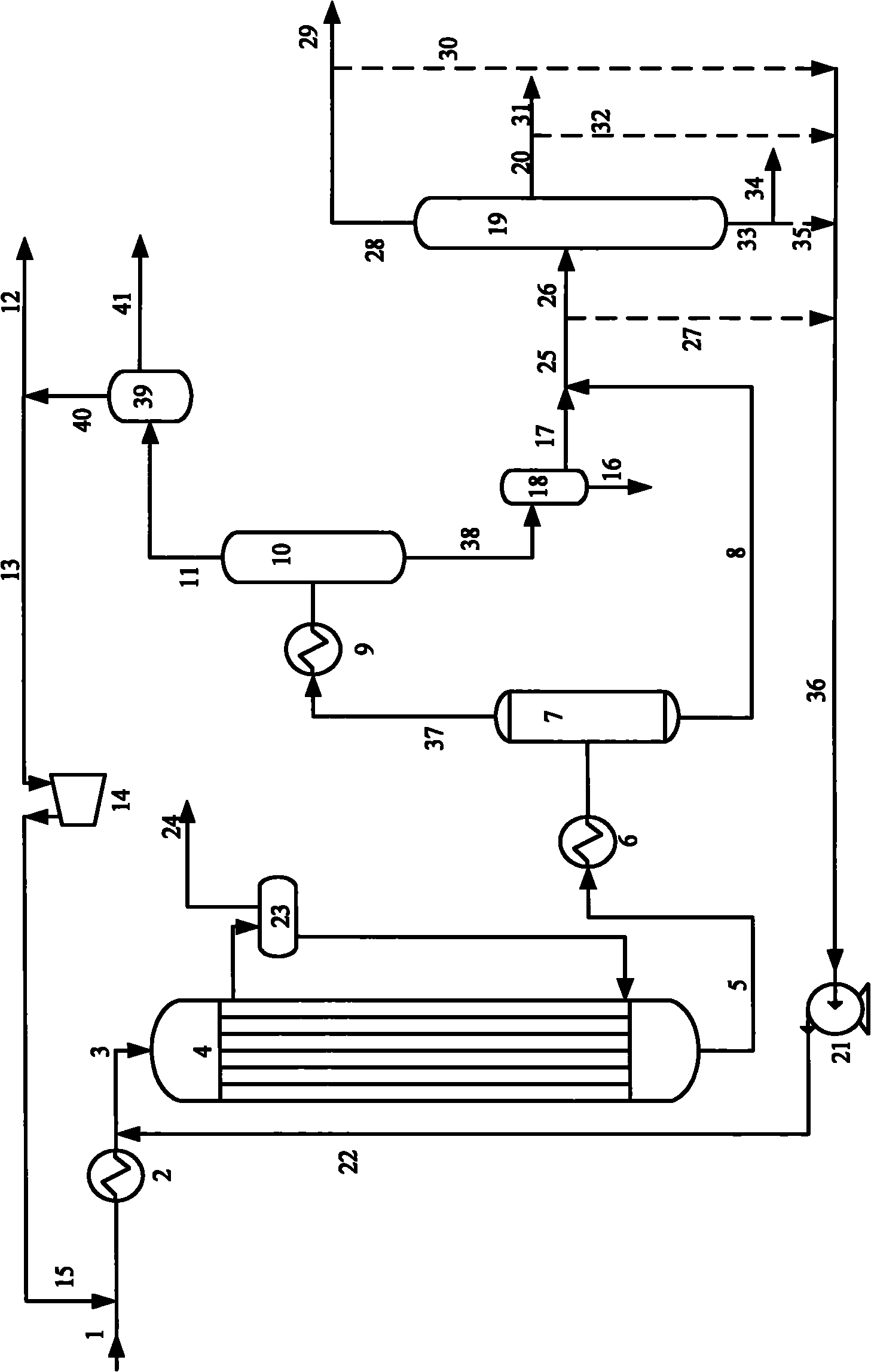

[0048] This embodiment adopts iron-based Fischer-Tropsch synthesis catalyst, figure 2 in the process flow. The catalyst is prepared by the precipitation method, and the main components are Fe, Cu, alkaline earth metals, K and SiO 2 , The catalyst weight composition is 100Fe:5Cu:5K:25SiO2. The catalyst needs to be reduced by syngas before introducing the raw material synthesis gas. Reduction reaction conditions: the pressure is 0.5MPa, and the reaction temperature is 300°C. After reduction, it is lowered to 150°C to introduce fresh raw material synthesis gas. H of purified raw syngas 2 The / CO ratio was 1.5.

[0049] The fresh raw material synthesis gas enters the fixed-bed Fischer-Tropsch synthesis reactor, and carries out the Fischer-Tropsch synthesis reaction under the action of an iron-based Fischer-Tropsch synthesis catalyst, and the reaction effluent is separated to obtain gaseous hydrocarbon products, liquid hydrocarbon products and water; The liquid hydrocarbon pr...

Embodiment 3

[0058] This embodiment adopts cobalt-based Fischer-Tropsch synthesis catalyst, figure 1 in the process flow. The catalyst adopts a conventional preparation method, impregnating a solution containing cobalt nitrate and zirconium nitrate on a silica carrier, drying and calcining to obtain the catalyst. The content of metal cobalt in the finished catalyst is 22%, and the addition amount of auxiliary agent zirconium is 2.5%. The catalyst is filled in each reaction tube, and the pressure drop of each reaction tube is as close as possible. Before the introduction of syngas, the catalyst needs to pass through H 2 Reduction, reduction reaction conditions: the pressure is 0.5MPa, and the reaction temperature is 400°C. After reduction, it is lowered to 150°C to introduce fresh raw material synthesis gas. H of purified raw syngas 2 The / CO ratio was 2.0.

[0059] The fresh raw material synthesis gas enters the fixed-bed Fischer-Tropsch synthesis reactor, and the Fischer-Tropsch syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com