Visual gas hydrate experimental device

A gas hydrate and experimental device technology, applied in measurement devices, chemical method analysis, instruments, etc., can solve problems such as small visual range and small reaction volume, and achieve the goal of overcoming short bubble travel, increasing gas-liquid contact area, and increasing The effect of gas solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

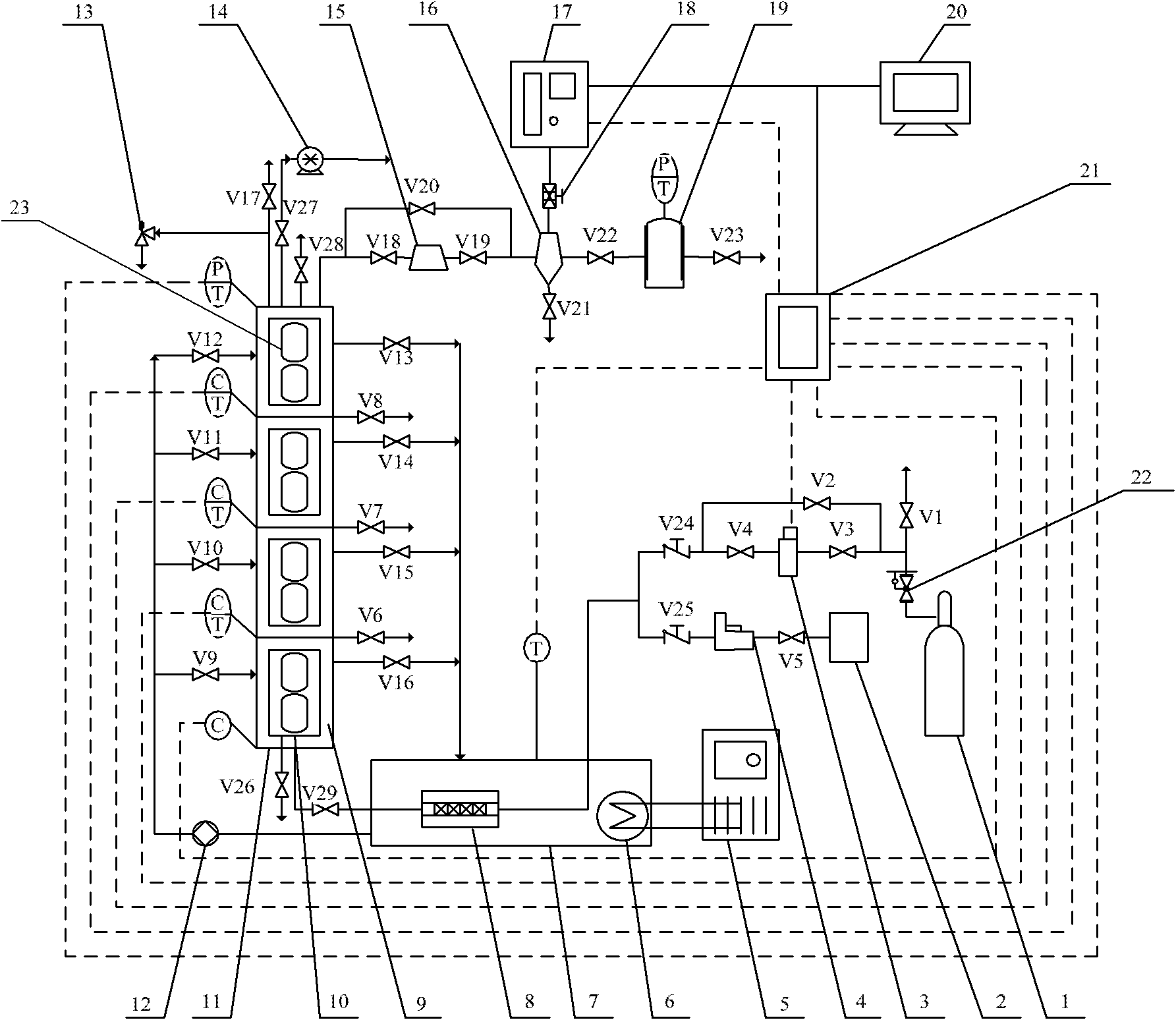

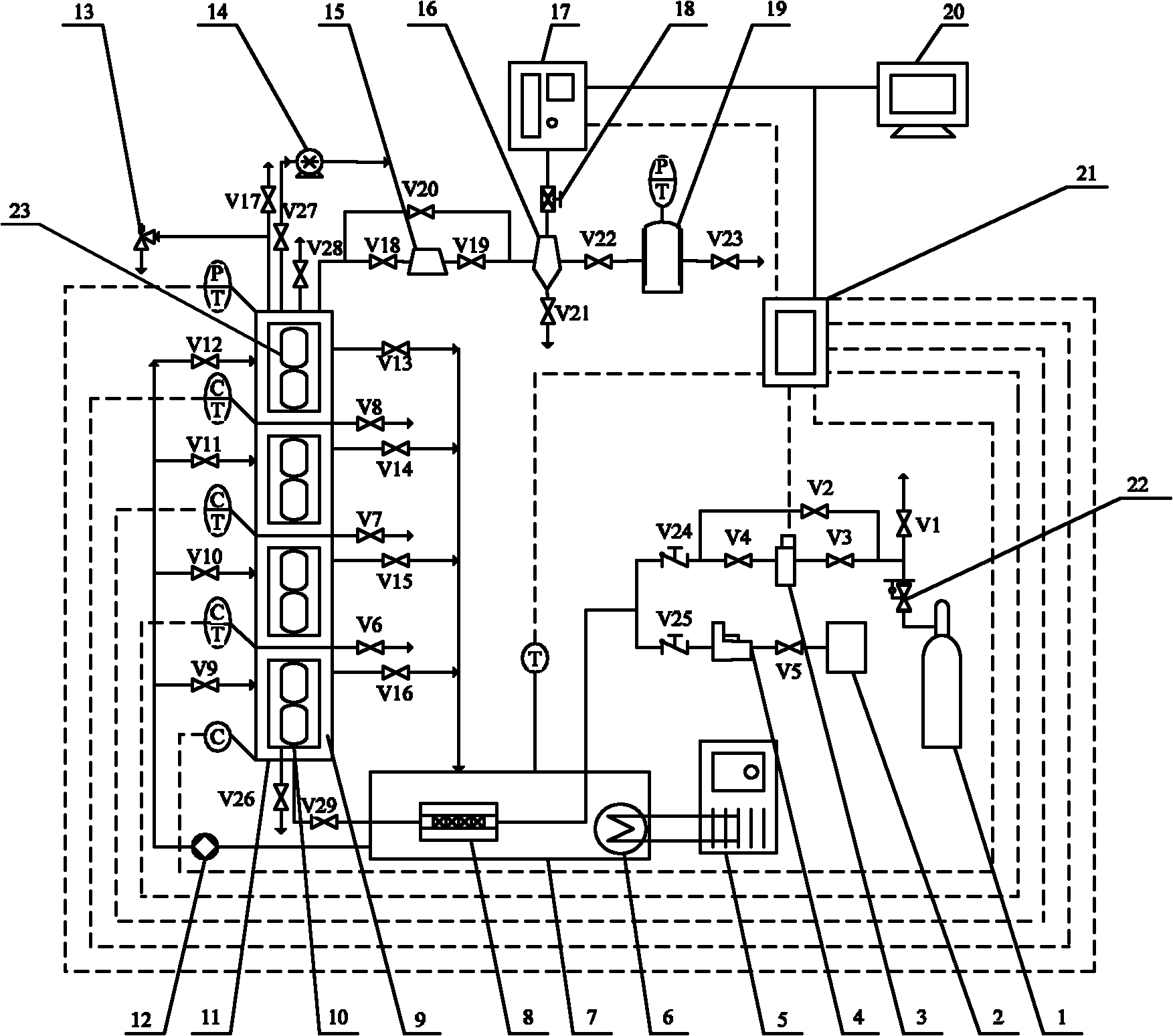

[0025] attached figure 1 The marks in each are: 1. Gas cylinder, 2. Liquid tank, 3. Mass flow controller and integrator, 4. Metering pump, 5. Refrigeration system, 6. Heat exchanger, 7. Constant temperature water tank, 8. Static mixing Device, 9, water jacket, 10, distributor, 11, reactor, 12, pressurized water pump, 13, safety valve, 14, vacuum pump, 15, PID pressure regulating valve, 16, gas-liquid separator, 17, gas phase Chromatograph, 18, automatic gas sampler, 19, gas cylinder, 20, computer, 21, data acquisition card, 22, pressure reducing valve, 23, window. V1~V29 are all valves, except check valve V24 and check valve V25, the rest are stop valves.

[0026] Such as figure 1 As shown, the visualized gas hydrate experimental device of the present invention includes a visualized hydrate reactor, a steady flow gas supply, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com