A preparing method of a monodisperse phenolic resin carbon microbead

A technology of phenolic resin and phenolic resin liquid is applied in the field of preparation of monodisperse phenolic resin carbon microspheres, which can solve the problems of difficulty in precise control of product particle size, high drying temperature and curing temperature, poor sphericity of microspheres, etc. The use of chemical reagents, the reduction of production costs, and the effect of easy adjustment of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of monodisperse phenolic resin carbon microsphere provided by the invention can comprise the following steps:

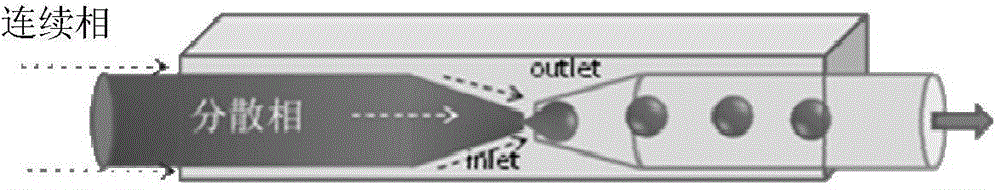

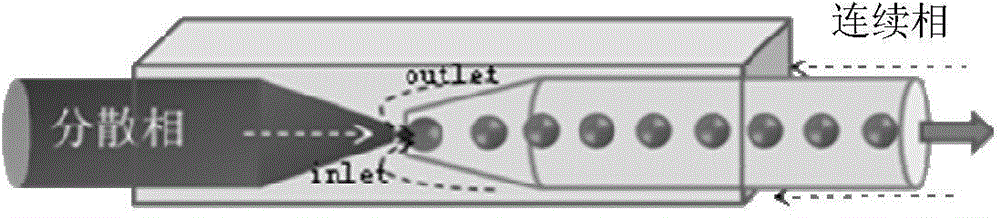

[0047] (1) the water-soluble phenolic resin that the viscosity is 5-1000mp s, solid content is 30-60% is used as dispersed phase solution; Surfactant is mixed with difficult volatile oil, is mixed with surfactant mass percentage concentration is 1%-10% organic solution is used as the continuous phase solution; the dispersed phase solution and the continuous phase solution are respectively loaded into syringes, the syringes are respectively placed on micro-injection pumps, and the syringes are connected to microchannels for reaction device, and then respectively inject the dispersed phase solution and the continuous phase solution into the microchannel reactor through the micro-injection pump, so that the dispersed phase solution and the continuous phase solution flow into the microchannel reactor, and the dispersed phase solution and the ...

Embodiment 1

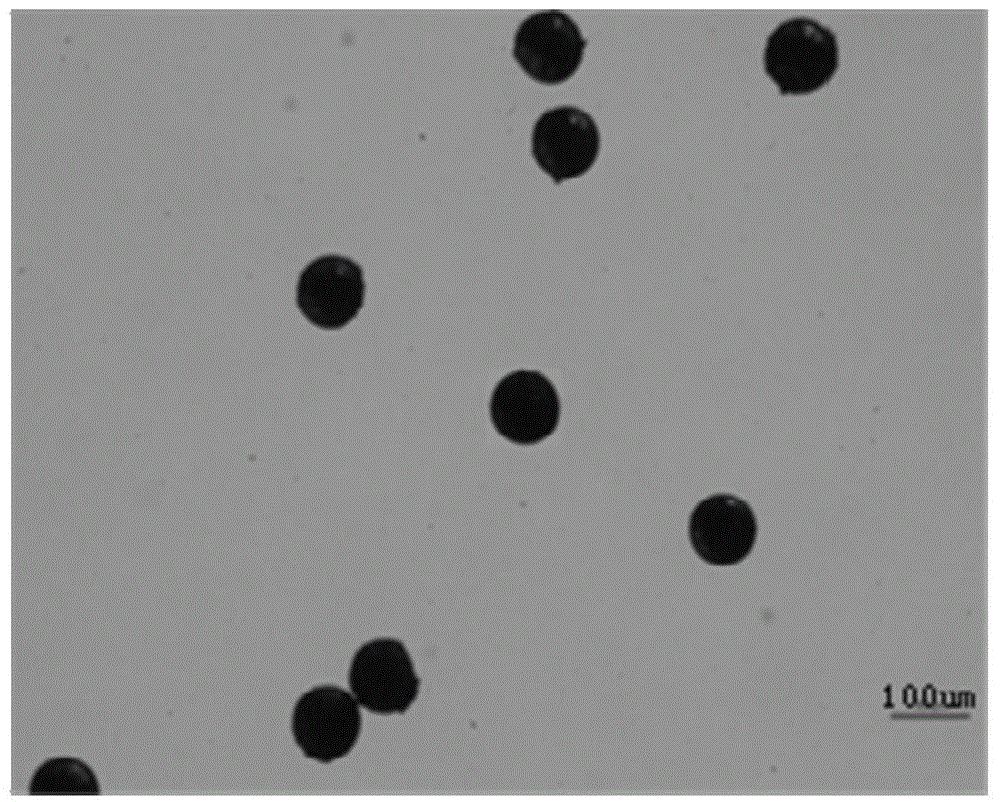

[0053] Weigh 2.0g EM90 and add it into a beaker containing 100mL mineral oil, stir slowly with a magnet, and filter to obtain a continuous phase solution; commercially available water-soluble phenolic resin with a viscosity of 60mp s and a solid content of 47% is filtered, A dispersed phase solution is obtained. The two solutions were respectively loaded into 20mL syringes, placed on a micro-injection pump, and connected to a microchannel reactor. The flow direction of the phase solution is reversed (such as Figure 1b shown), and set the flow rate of the dispersed phase solution to be 0.5mL / h, and the flow rate of the continuous phase solution to be 5mL / h, so that the two phases meet at the nozzle of the collection tube in the microchannel reactor, and continuously generate uniform phenolic resin liquid drop. Use a collector equipped with liquid paraffin to collect the generated droplets, put them in an oven for temperature-programmed solidification, keep at 70°C for 1.5h, ...

Embodiment 2

[0055] The paraffin wax solution containing EM90 with a mass percent concentration of 2% is used as the continuous phase solution, and the water-soluble phenolic resin with a viscosity of 15mp·s and a solid content of 47% is used as the dispersed phase solution. The inlet diameter of the microchannel reactor used is 160 μm, and the outlet diameter is 200 μm. Reverse the flow direction of the dispersed phase solution and the continuous phase solution (such as Figure 1b shown). The flow rate of the dispersed phase solution was controlled to be 0.5 mL / h, and the flow rate of the continuous phase solution was 3 mL / h. Other steps and parameters are the same as in Example 1. The phenolic resin droplets with a particle diameter of about 180 μm were obtained. The particle size of the obtained monodisperse phenolic resin microspheres is 115 μm, the particle size deviation CV<3%, and the particle size is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com