Multidirectional combined type circulating upsetting device and upsetting method

A compound and upsetting technology, applied in the field of plastic forming, can solve the problems of small deformation, high processing temperature, and material side cracking, and achieve the effects of large deformation, improved ultra-fine degree, and sufficient flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

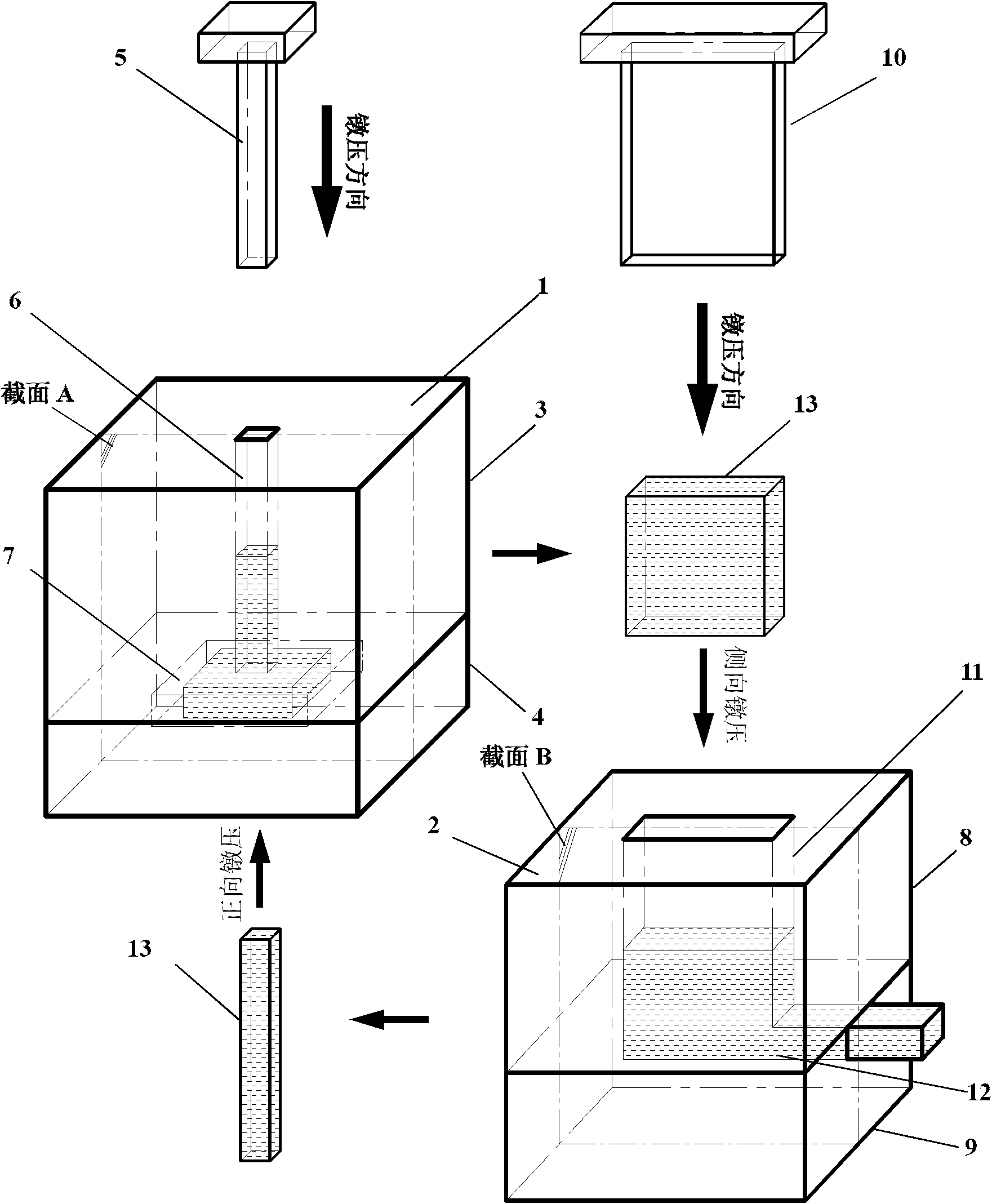

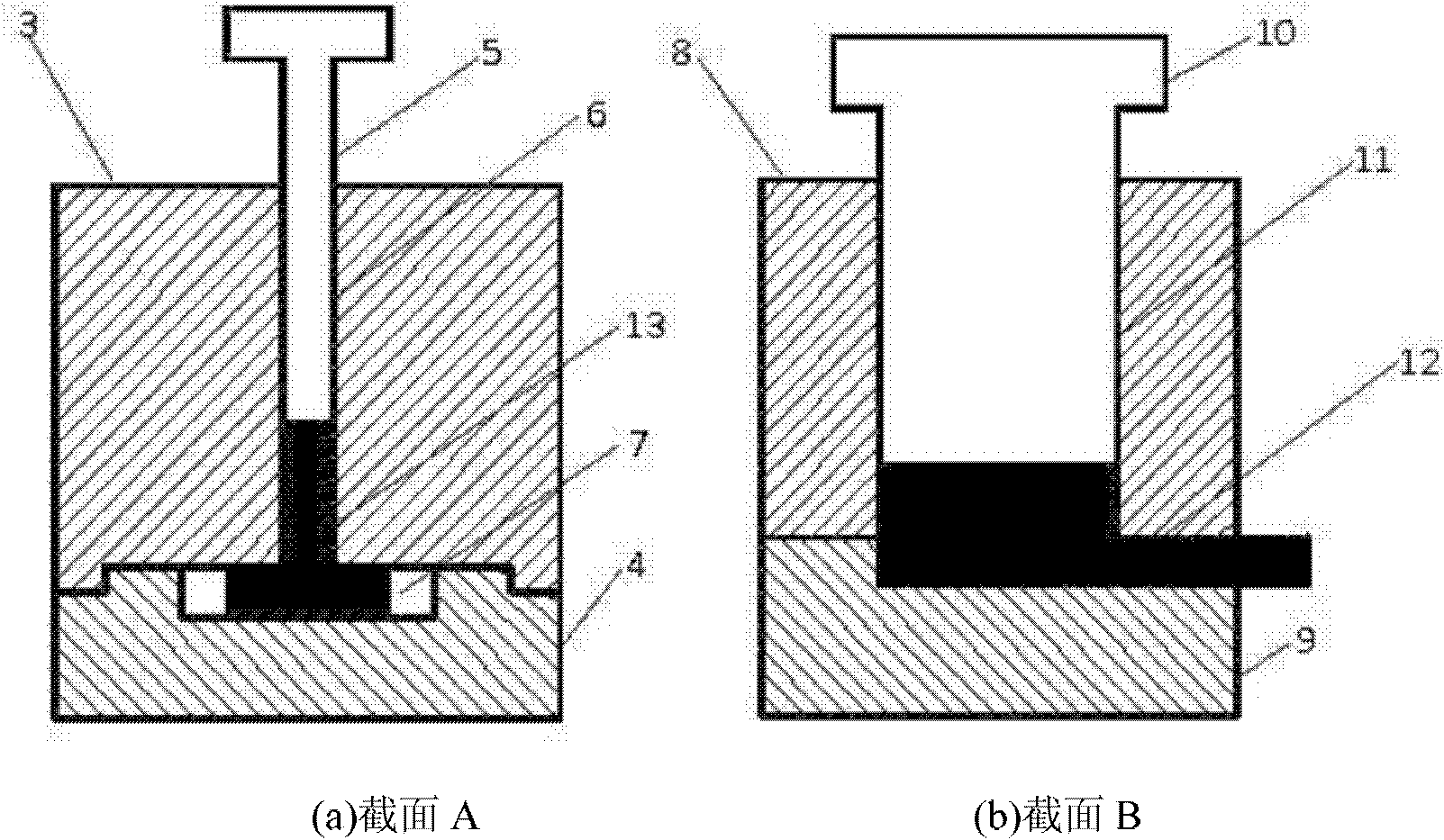

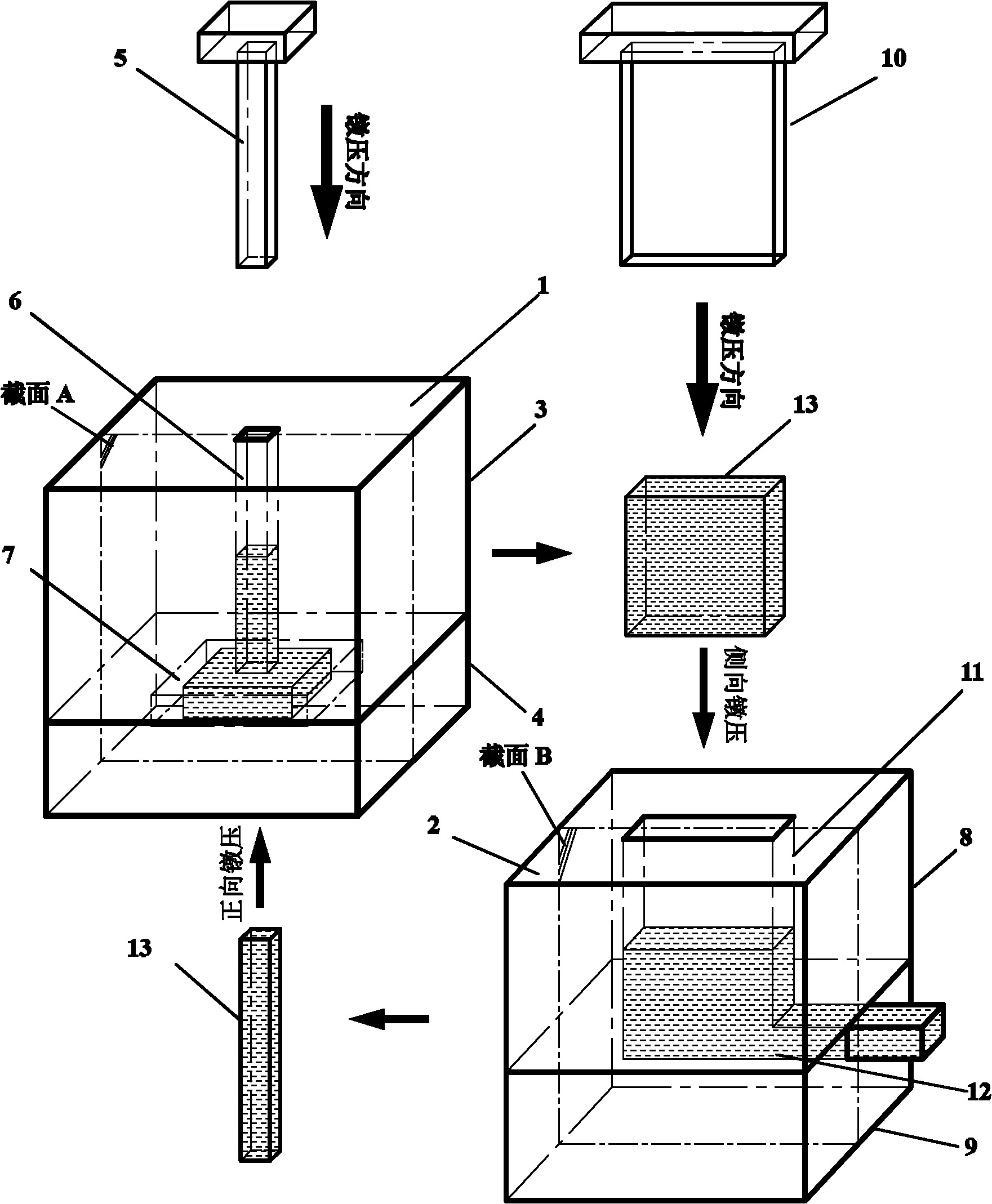

[0028] Such as figure 1 As shown, the upsetting device involved in the following embodiments includes: a forward upsetting device 1 and a side upsetting device 2, wherein:

[0029] The positive upsetting device 1 includes: a positive upper die 3, a positive lower die 4 and a forward punch 5, wherein: the positive upper die 3 and the positive lower die 4 arranged up and down are in contact, and the cross section of the forward punch 5 The size matches the section of the positive model cavity 6;

[0030] The central axis of the positive mold 3 is provided with a positive mold cavity 6 from top to bottom, and the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com