Horizontal solid-liquid mixer

A solid-liquid mixing, horizontal technology, used in mixers, mixers with rotary stirring devices, dissolution and other directions, can solve the problems of increasing the dispersion time, prolonging the mixing time, and not solving the problems, and achieves prolonging the mixing time and mixing efficiency. High, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

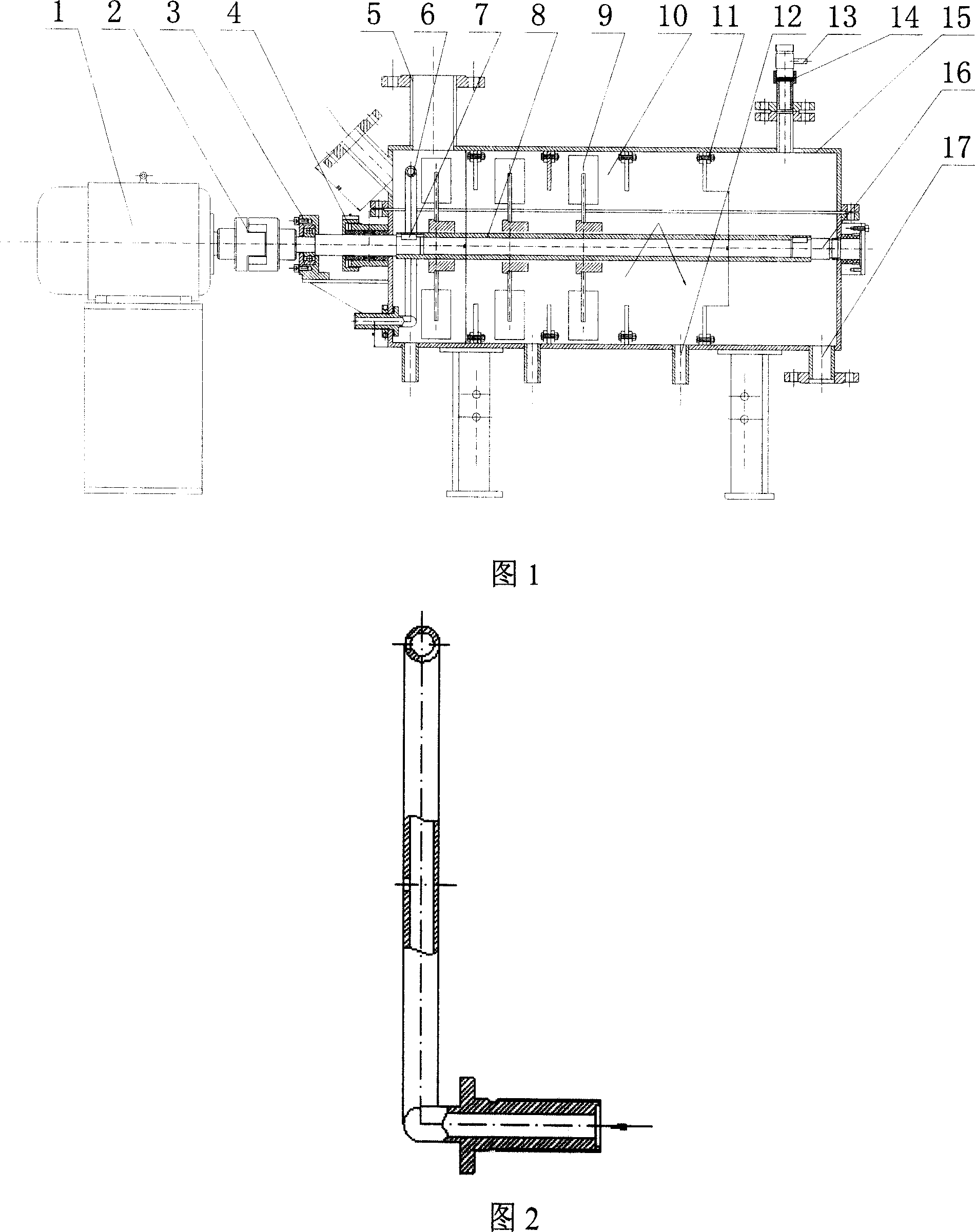

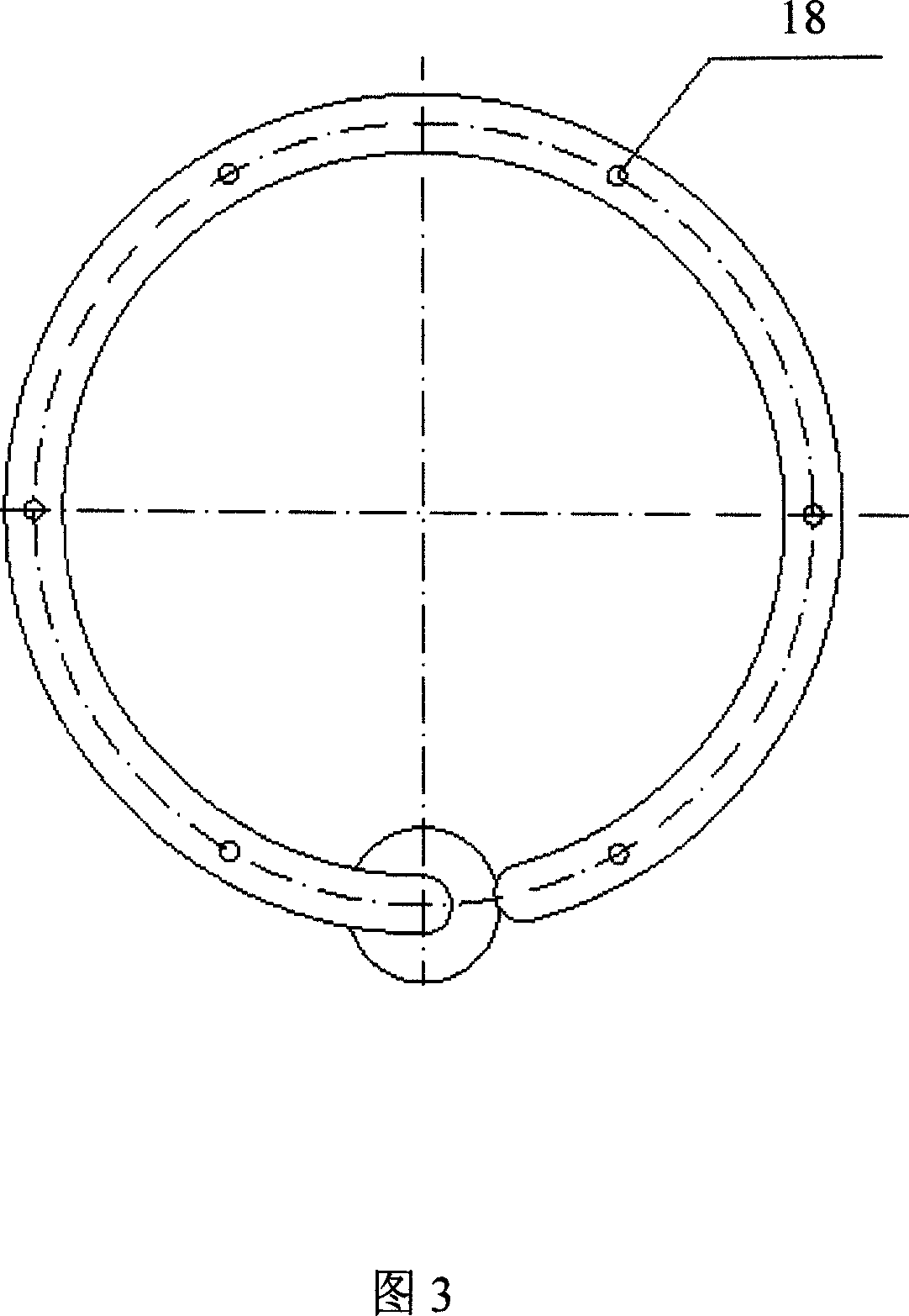

[0022] As shown in Figures 1, 2 and 3, the horizontal solid-liquid mixing device of the present invention mainly includes a mixing chamber 10 surrounded by a cylinder 15, on which a solid feed port 5, a liquid feed pipe 6, a Material port 17, exhaust port 13, cleaning port 12, cylinder body 15 center has stirring shaft 8. The rotating shaft 7 is sealed by the stuffing box 4 . The shaft of the horizontal solid-liquid mixing device is composed of a rotating shaft 7, a stirring shaft 8 and a stirring paddle 9, which can be easily disassembled. The liquid feed pipe 6 is provided with 4 to 20 holes of 0.5 to 5 mm. In this embodiment, 6 small holes with a diameter of 4 mm are uniformly distributed. Change the number and position of the holes to prevent the powder from flying when the powder material is added. The stirring paddle 9 is fixed on the stirring shaft 8, the distance between the outer edge of the stirring paddle 8 and the inner wall of the cylinder body 15 is 5.5mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com