Patents

Literature

61results about How to "No sedimentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing solution for hard disk magnetic head and preparation method thereof

ActiveCN102174294AImprove suspension stabilityImprove dispersion uniformityOther chemical processesPolishing compositions with abrasivesHydrocarbon solventsMachined surface

The invention discloses polishing solution for a hard disk magnetic head and a preparation method thereof. The polishing solution is mainly prepared from diamond abrasive particles, a dispersing agent, a corrosion inhibitor, a phase transfer solvent, an oil phase medium regulator and a hydrocarbon solvent, wherein the average particle size of the diamond abrasive particles is 30 to 150nm, the particle size distribution of the particles is 20 to 300nm, and the length-diameter ratio of the particles is 1.0 to 2.0. The preparation method comprises the following steps of: mixing diamond powder and a surface modifier, grinding, removing impurities, and grading to obtain suspension slurry; adding the phase transfer solvent into the suspension slurry, and stirring and dispersing the system; removing fine particles and coarse particles in the phase transfer solvent system by grading to ensure that the particle size distribution and concentration of the diamond abrasive particles meet the requirements; and transferring to the hydrocarbon solvent, adding the oil phase medium regulator, the dispersing agent and the corrosion inhibitor, and uniformly stirring to obtain the polishing solution for the hard disk magnetic head. The polishing solution prepared by the method has high suspension stability and dispersion uniformity, and high polishing efficiency during polishing, and a machined surface has high quality.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Lithium ion battery anode slurry and preparation method thereof

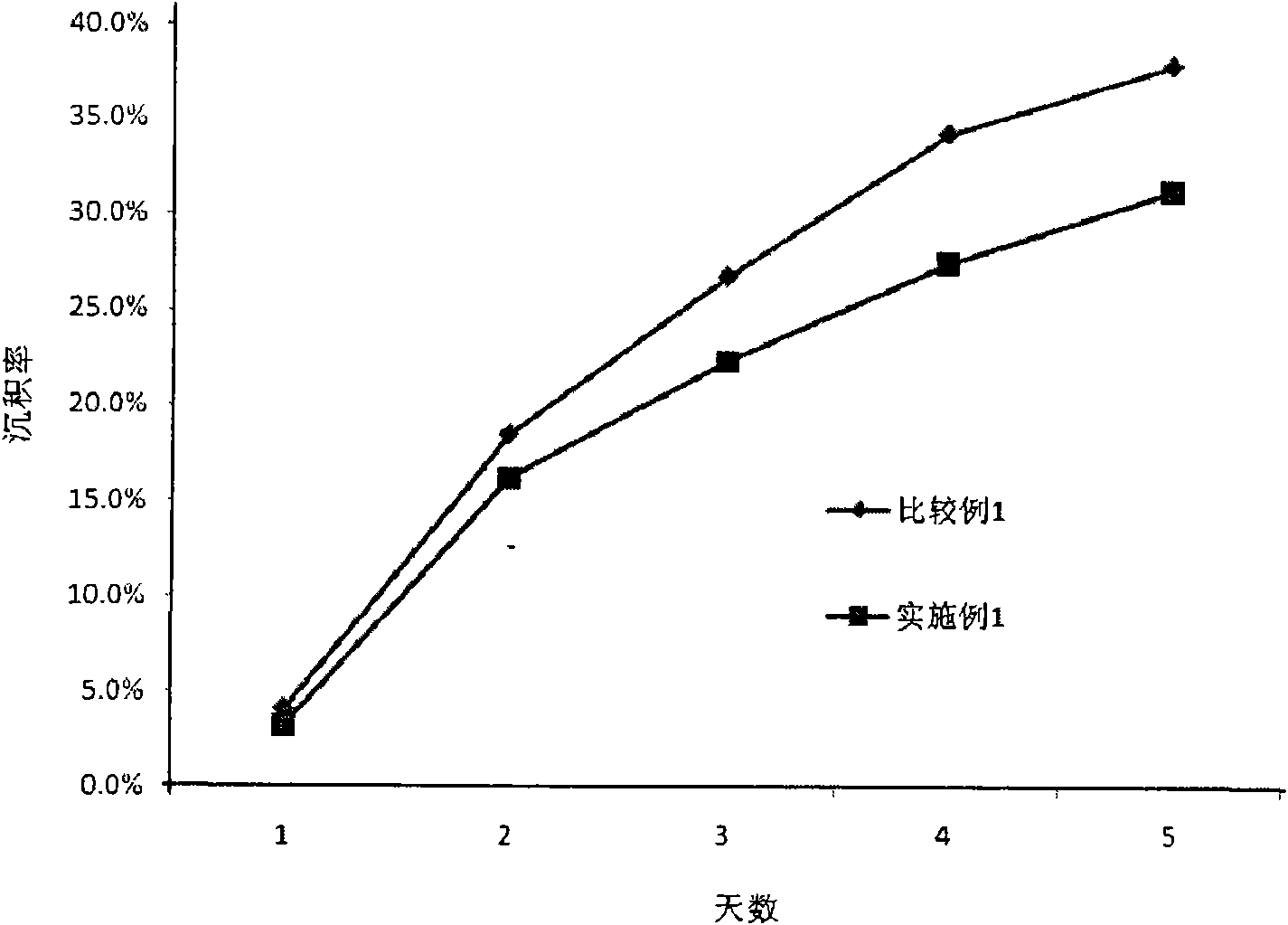

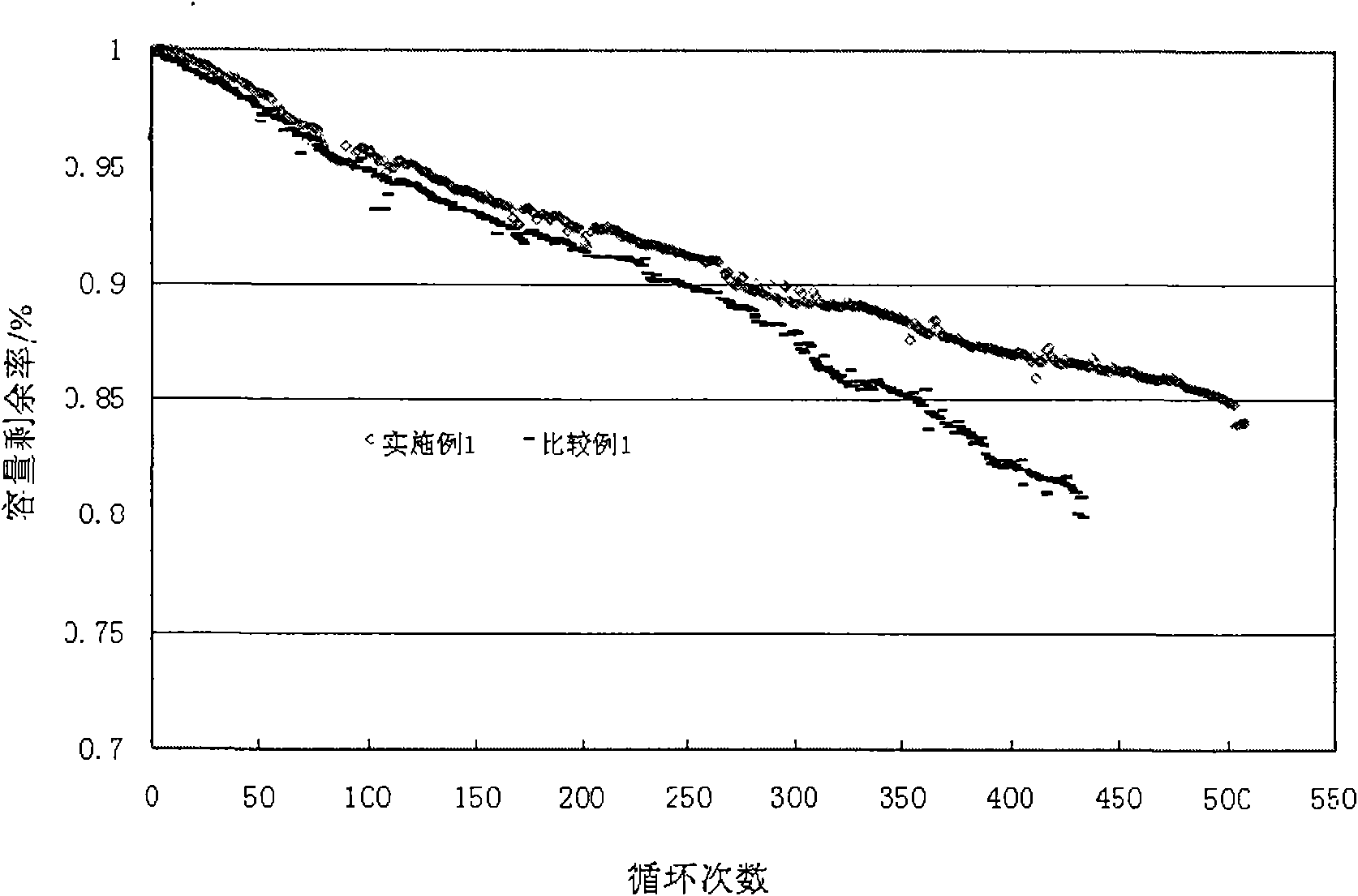

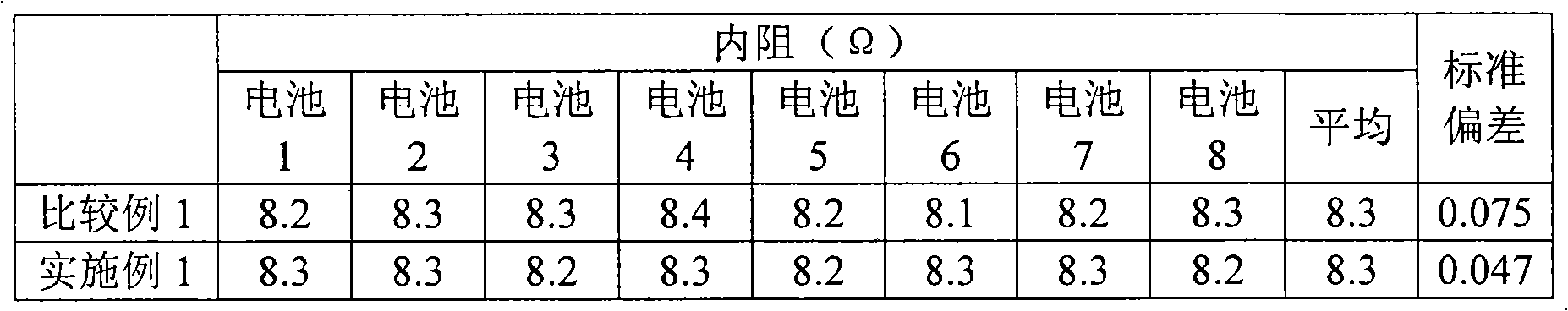

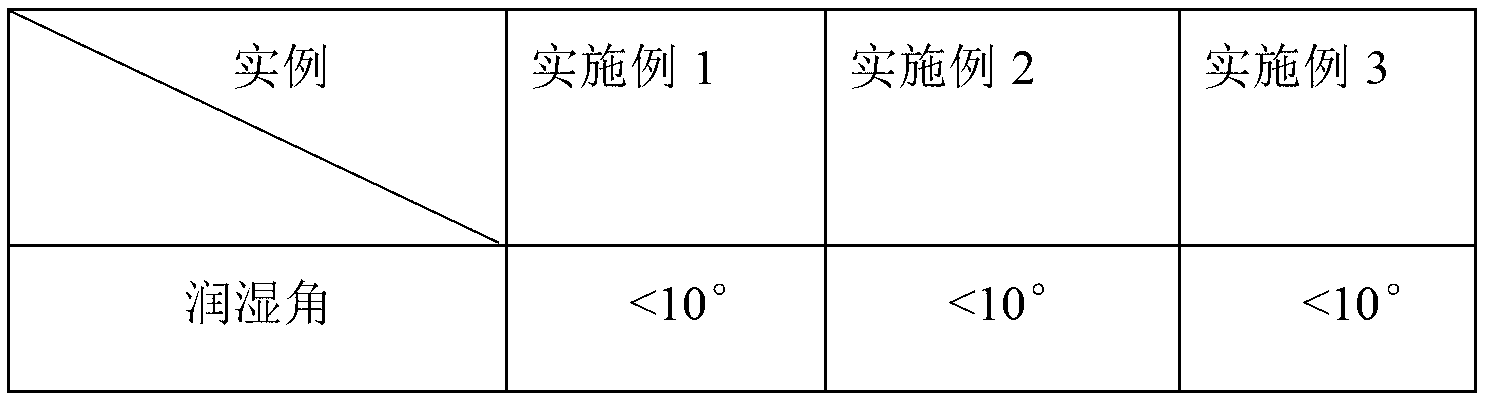

InactiveCN101609881ALow viscosityImprove stabilityElectrode manufacturing processesSecondary cellsSolventCurrent collector

The invention belongs to the field of lithium batteries and discloses lithium ion battery anode slurry and a preparation method thereof. The formula of the slurry adopts the following components according to parts by weight: 63-89 parts of lithium manganate, 1.8-3.6 parts of conductive agent, 2.5-4.8 parts of binding agent, 2-15 parts of dispersant and 58-80 parts of solvent. As the dispersant is added in the slurry, the viscosity of the slurry is reduced, the stability of the slurry is improved, and the phenomenon of slurry deposition is avoided in the coating process of pole pieces, therefore, the consistency of the slurry and the consistency of the distribution of the slurry on a current collector aluminum foil are improved, and the consistency and the cycling capability of the battery can be improved.

Owner:JIANGSU FRONT NEW ENERGY

Solder paste for soft brazing of aluminum and aluminum alloy and preparation method thereof

InactiveCN103317260AHigh silver contentAlleviate electrode potential differenceWelding/cutting media/materialsSoldering mediaElectrode potentialPolyol

The invention relates to a solder paste for soft brazing of aluminum and aluminum alloy and a preparation method thereof. The solder paste consists of two parts, i.e., braze alloy powder and a flux, wherein the composition of the braze alloy powder comprises the following components in percentage by weight: 15-30 percent of tin, 1-3 percent of silver and the balance of lead; the composition of the flux comprises the following components in percentage by weight: 5-15 percent of heavy metal fluoride, 65-75 percent of hydrofluoride of aminopolyether polyol and 10-25 percent of ethylene glycol. According to the solder paste and the preparation method thereof, the tin-lead-silver alloy is used as a braze for brazing the aluminum; during brazing, the silver and the aluminum in the braze react, a layer of silver-aluminum solid solution is formed on a boundary surface of the braze and the aluminum, the electrode potential difference between the aluminum and the braze is relieved, and the corrosion resistance of a brazed joint is greatly improved.

Owner:天津市恒固科技有限公司

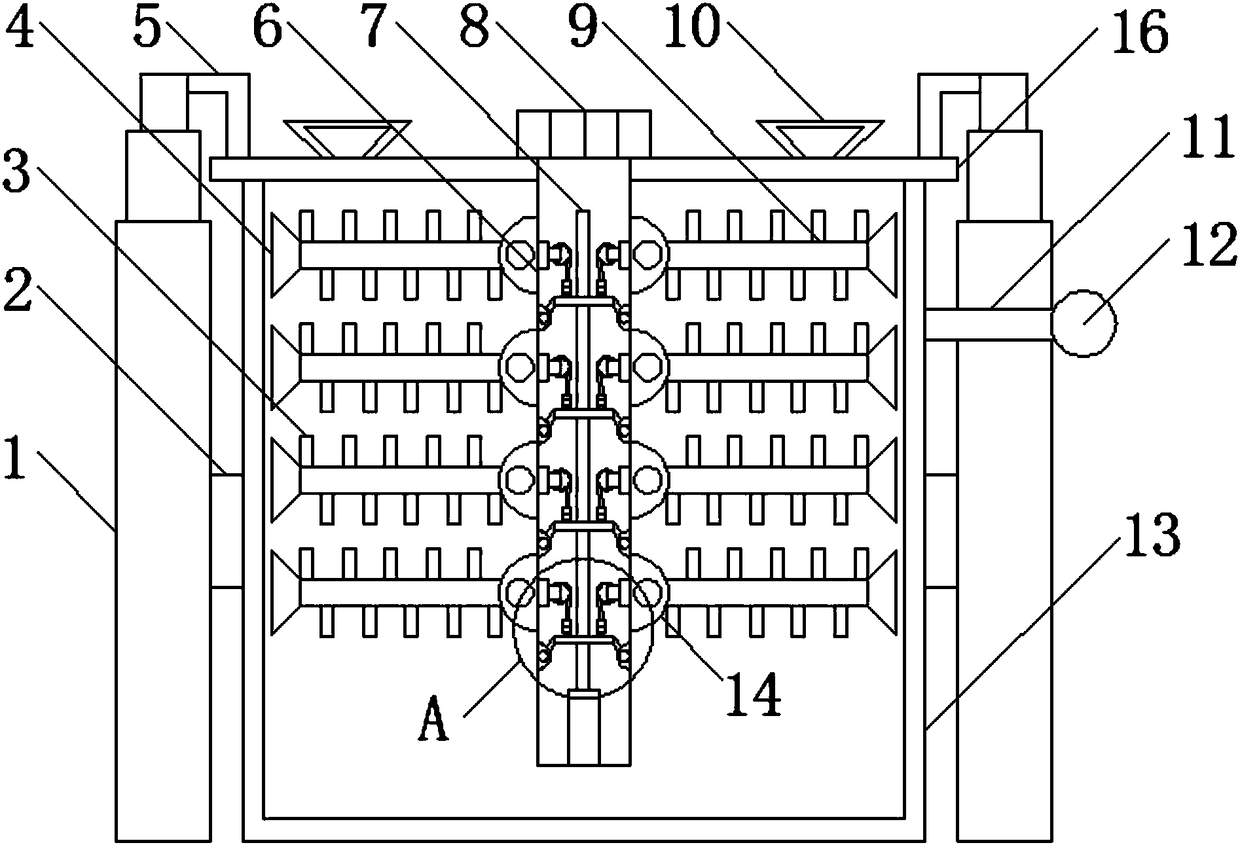

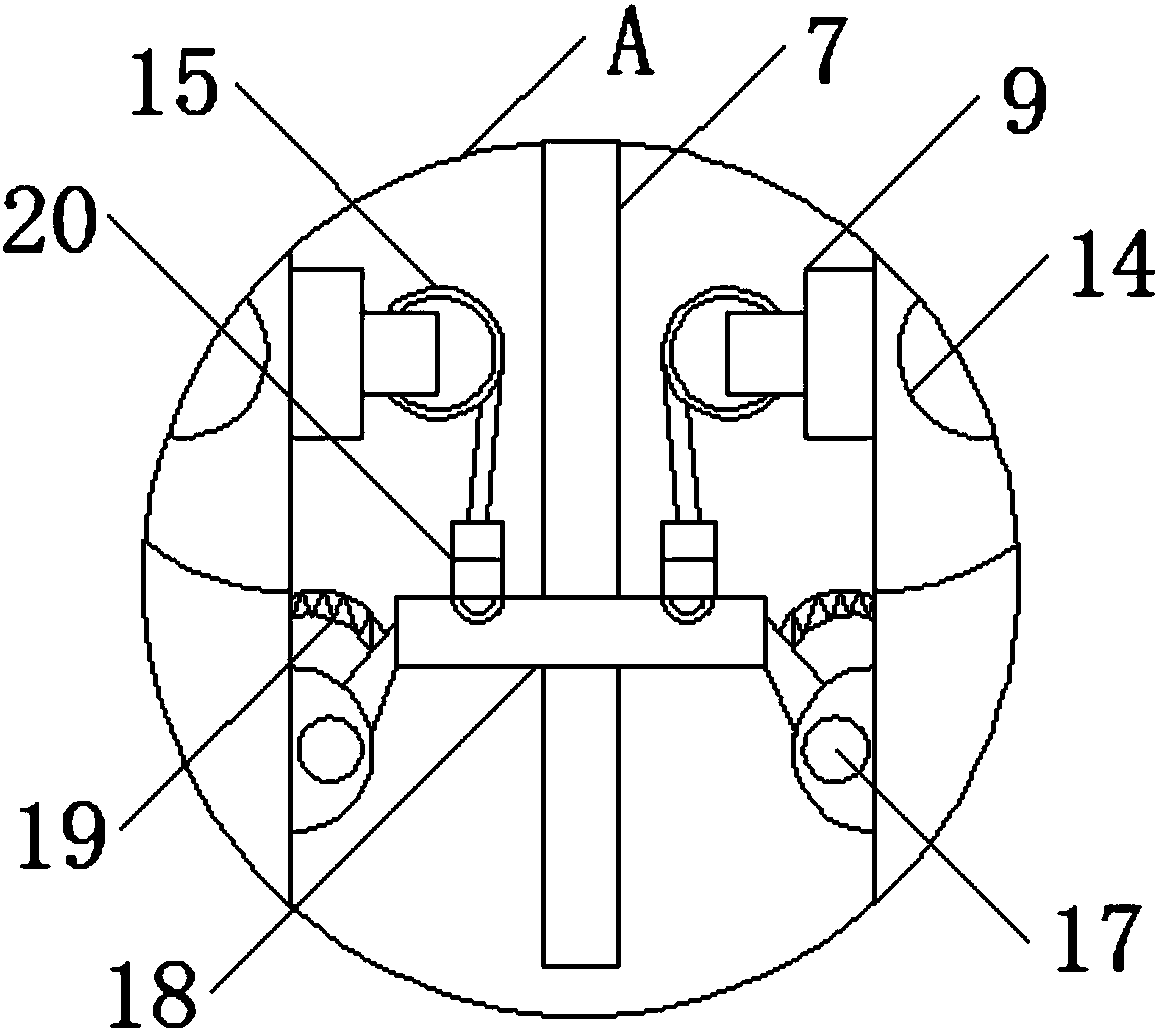

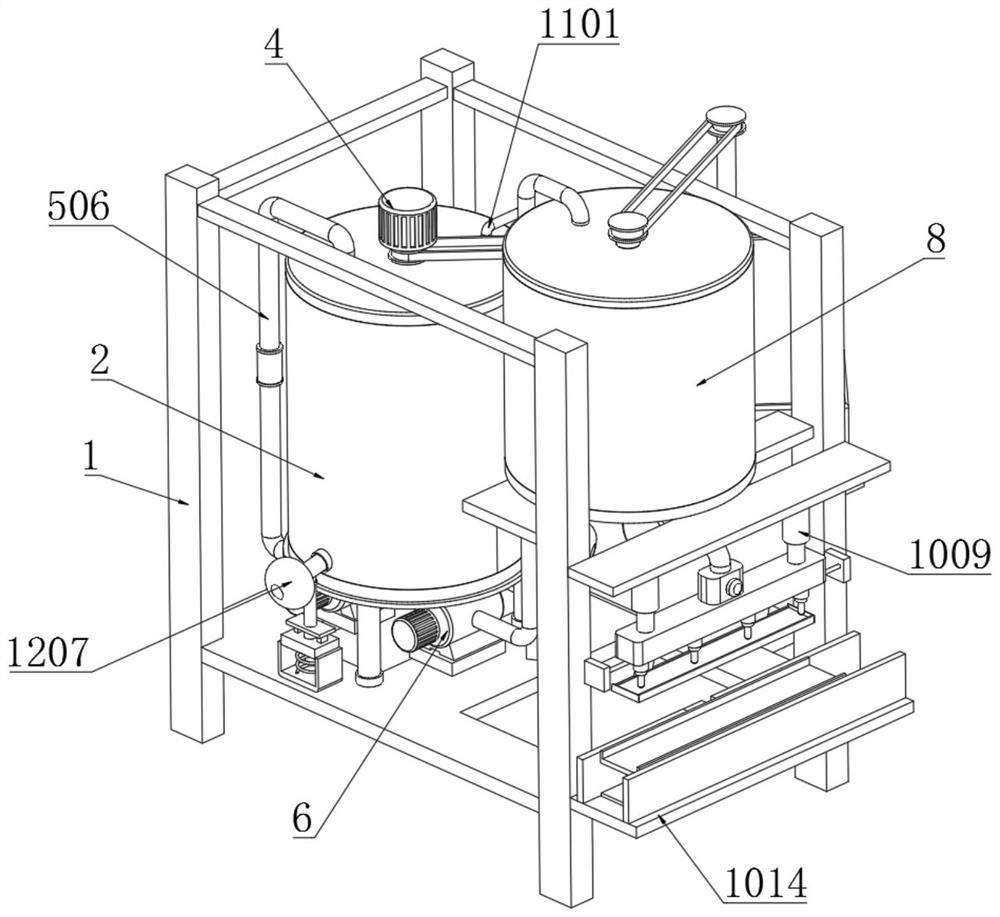

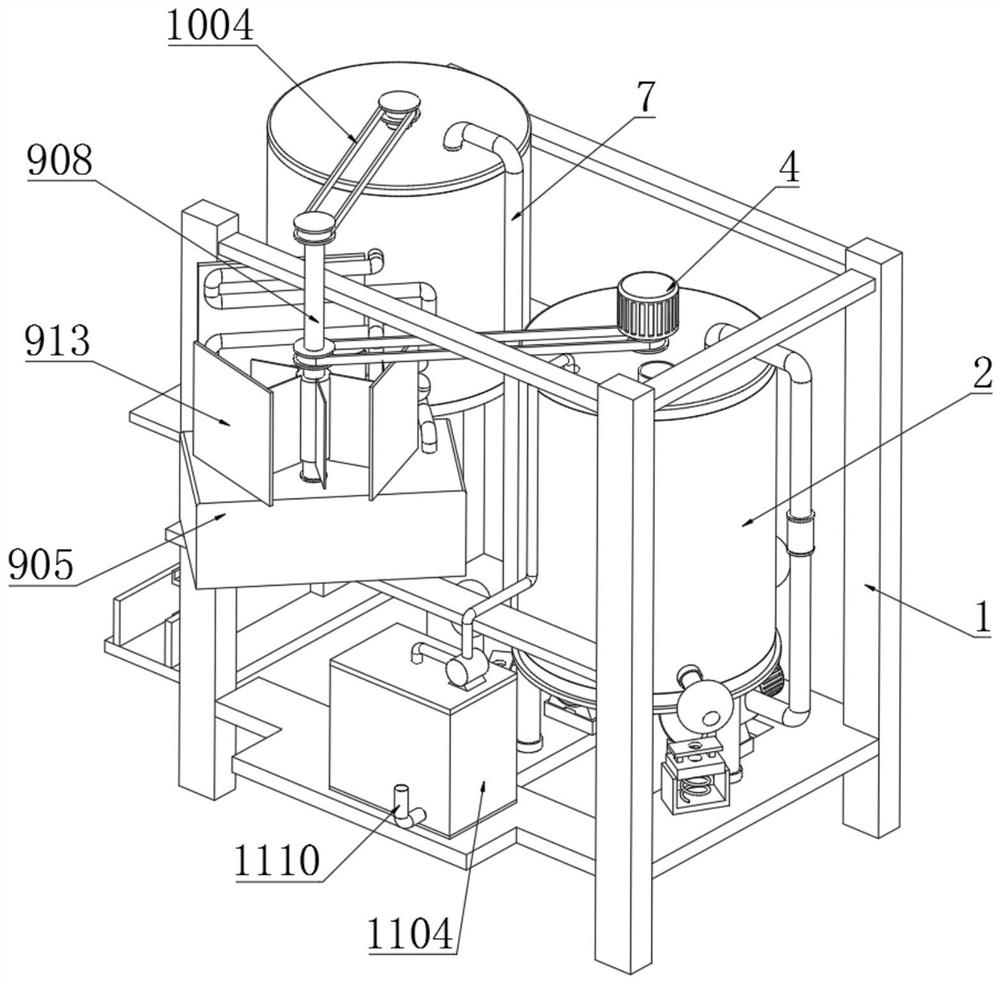

Uniformly mixing vacuum homogenization emulsifying machine

InactiveCN108246136AEasy to cleanStir wellTransportation and packagingMixing methodsEngineeringVacuum pump

The invention discloses a uniformly mixing vacuum homogenization emulsifying machine in the technical field of emulsifying machine. The uniformly mixing vacuum homogenization emulsifying machine comprises two groups of telescopic brackets, wherein opposite ends of the two groups of telescopic brackets are connected with an emulsifying pot by connecting shafts; tops of the telescopic brackets are connected with sealing covers by fixing rods; motors are arranged at the tops of the sealing covers; output ends of the motors are connected with rotating shafts; feeding ports are formed in the tops of the sealing covers; outer walls of the rotating shafts are connected with stirring rods by rotating shaft bases; stirring bars are uniformly arranged on outer walls of the stirring rods; a scrapingplate is arranged at one end of each stirring rod close to an inner wall of the emulsifying pot; second rotating bases are connected with a left end and a right end of a bearing plate; an air suctionpipe is arranged on a right outer wall of the emulsifying pot; and the other end of the air suction pipe is connected with a vacuum pump. The uniformly mixing vacuum homogenization emulsifying machinenot only can stir more uniformly, but also enables the scraping plate to better clean materials on the inner wall of the emulsifying pot, more rapidly takes out the materials, has no material deposition phenomenon, and is simple in structure and convenient to use.

Owner:扬州市钰翔轻工机械设备厂

Dynamic bottom aeration system and aeration method thereof

PendingCN106517498AEliminate oxygenation blind spotsEvenly oxygenatedSustainable biological treatmentBiological water/sewage treatmentAeration systemNozzle

The invention provides a dynamic bottom aeration system and an aeration method. The system comprises two trusses, a truss moving unit, an aeration component, a scraper, a fan, a blow-brushing unit and a second driving device, wherein a bridge is arranged between the two trusses; the truss moving unit comprises a guide rail, truss rollers, a first driving device and limiting devices; the first driving device drives the truss to move on the guide rail; the aeration component comprises an aeration air supply pipe, aeration air supply branch pipes, a fixed support and aerators; the aeration air supply branch pipes are radially connected on the aeration air supply pipe; the aerators are communicated with the aeration air supply branch pipes; the scraper is arranged below the fixed support; the fan is communicated with the aeration air supply pipe and a blow-brushing air supply pipe; the blow-brushing unit comprises the blow-brushing air supply pipe, a blow-brushing air supply branch pipe and air nozzles; the blow-brushing air supply pipe and the aeration air supply branch pipes are concentric; one end of the blow-brushing air supply pipe is communicated with an air outlet of the fan and the other end is connected with the blow-brushing air supply branch pipe; the blow-brushing air supply branch pipe is installed on the fixed support; the air nozzles are arranged on the blow-brushing air supply branch pipe; the second driving device drives the aeration component and the blow-brushing unit to rotate. The system has the advantage of no blind area and dead center dynamic aeration oxygenation.

Owner:HUATIAN ENG & TECH CORP MCC

Method of detecting shell waterproof performance and spraying device of implementing same

InactiveCN105738042AEasy to cleanAffect aestheticsDetection of fluid at leakage pointEngineeringWater spray

The present invention relates to a method of detecting shell waterproof performance and a spraying device of implementing the same. A colored liquid having chromatic aberration with the inner wall of a shell is used as a water spraying experiment liquid, if the waterproof grade of the shell does not accord with the requirement, the colored liquid which has the chromatic aberration with the inner wall of the shell and is easy to observe infiltrates through the shell from the corresponding gaps, so that the inner wall infiltration situation and the infiltration points can be observed conveniently after the experiment is ended to open the shell. Meanwhile, the colored liquid used in the present invention can be cleaned, so that the residual colored liquid inside and outside the shell can be cleaned conveniently after the water spraying experiment, and the situation that the corresponding color deposits on the shell to influence the beautiful outlook of the shell is avoided.

Owner:HENAN PINGGAO ELECTRIC +2

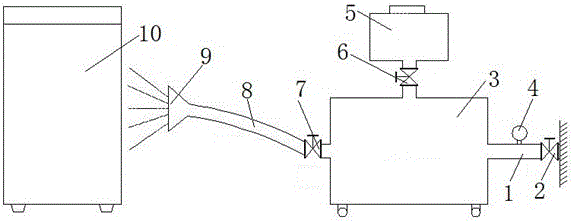

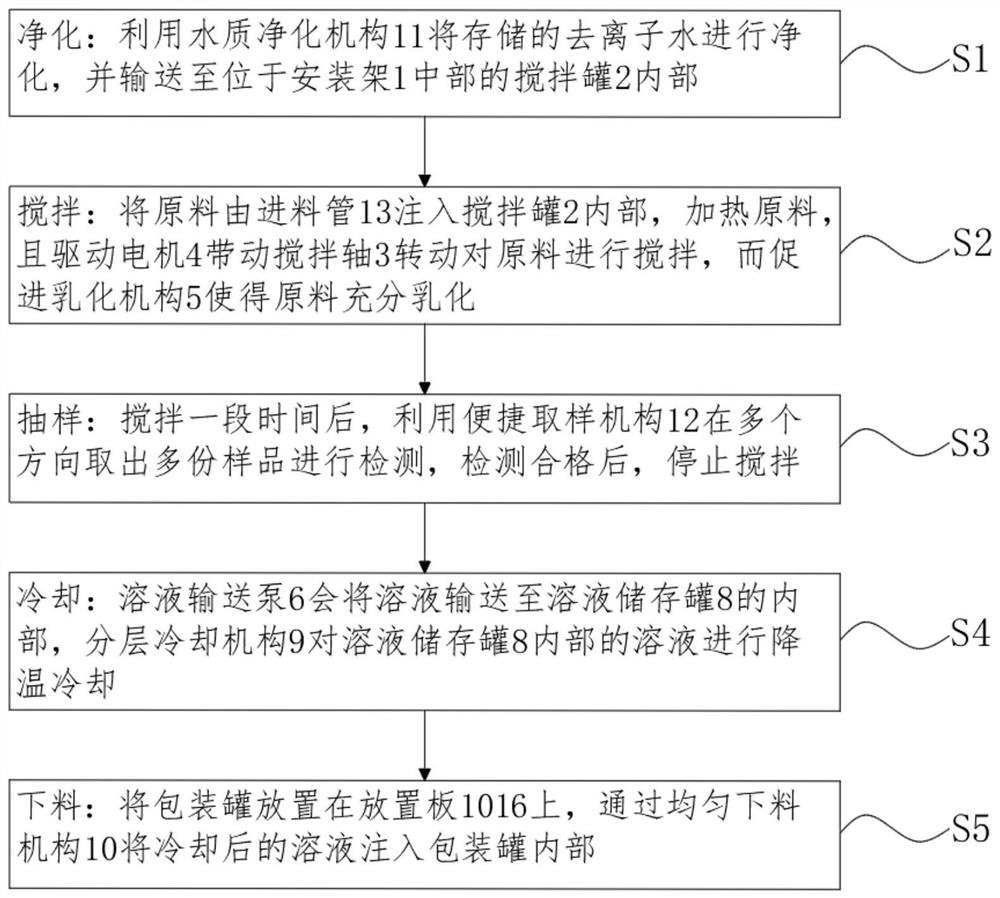

Preparation method of decontamination type laundry detergent

InactiveCN112169610AStir wellWell mixedWater/sewage treatment by irradiationFlow mixersProcess engineeringDrive motor

The invention discloses a preparation method of a decontamination type laundry detergent. The method comprises the following steps of: purification: purifying stored deionized water by using a water quality purification mechanism, conveying the purified deionized water into a stirring tank in the middle of a mounting frame; stirring: injecting raw materials into the stirring tank through a feedingpipe, heating the raw materials, and driving a stirring shaft to rotate by a driving motor so as to stir the raw materials, and fully stirring the raw materials through an emulsification promoting mechanism. The raw materials in the stirring tank can be fully mixed through the emulsification promoting mechanism, the raw materials can be fully mixed, and the situation that the quality of the prepared laundry detergent is unqualified due to uneven mixing of the raw materials is avoided, and meanwhile, through cooperative use of a circulating pump and a circulating conveying pipe, the mixed solution at the bottom of the stirring tank is pumped out and then re-injected into the stirring tank, the problem that the solution is deposited at the bottom of the stirring tank and cannot be fully mixed is avoided, raw materials are fully emulsified, raw material mixing is promoted, and the activity of the raw materials can be improved.

Owner:周燕芳

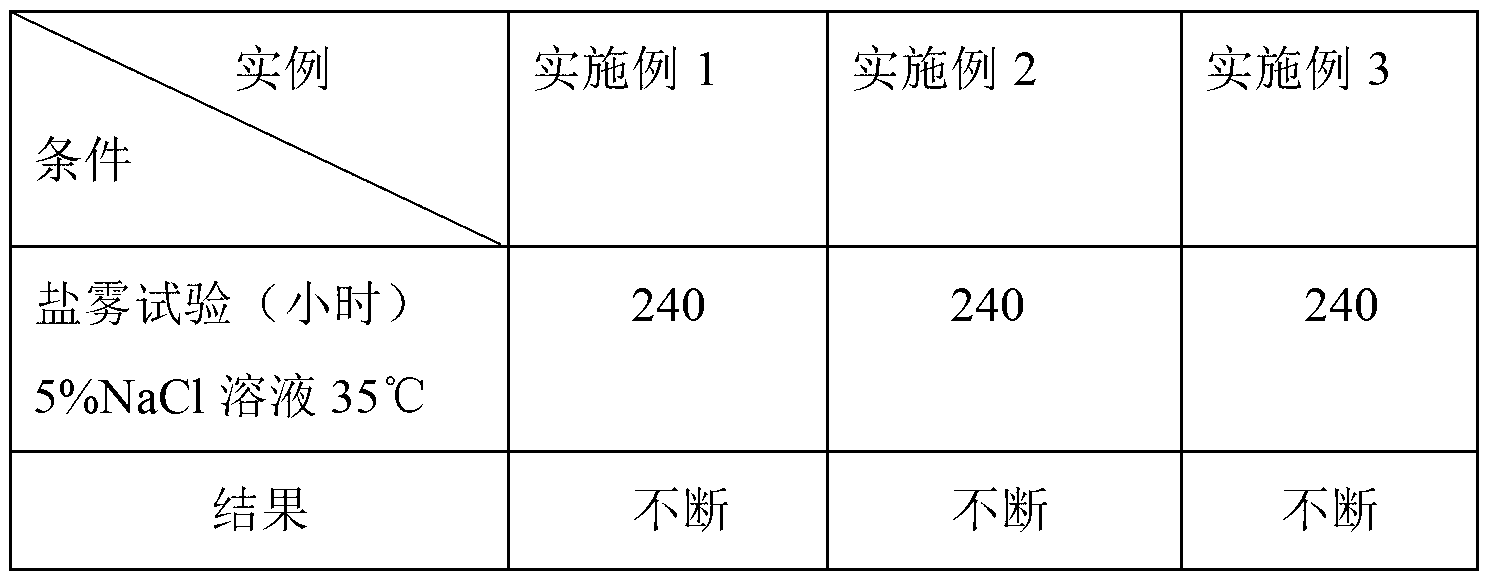

Processing method of ultrafine grinding wires

InactiveCN109176332ASave production spaceReduce preparation timeGrinding devicesPelletizingMelt spinning

The invention discloses a processing method of ultrafine grinding wires. The processing method comprises the following steps of preparation of a treatment solution; preparation of a master batch; andmelt spinning. In the processing method, without using absolute alcohol, the risk that the absolute alcohol is inflammable and explosive is solved; the ultrafine grinding wires do not need to be laidand aired, so that the production space is greatly saved; without tedious programs including manual pelletizing, sieving and drying, the production efficiency is improved; and with a simple and convenient technology, the loss of diamond micropowder is reduced, and the cost is effectively lowered. In addition, for the ultrafine grinding wires produced by the processing method, the content of the diamond micropowder is full in content and uniform in distribution, so that the rigidity and the abrasion resistance of brush wires are improved, and the service life of the brush wires is prolonged; inthe use process, the fine polishing effect of the surface of a workpiece can be better; the diameter can be from 0.08mm to 0.149mm, and the blank of a product in the domestic and foreign markets is filled.

Owner:赵明余

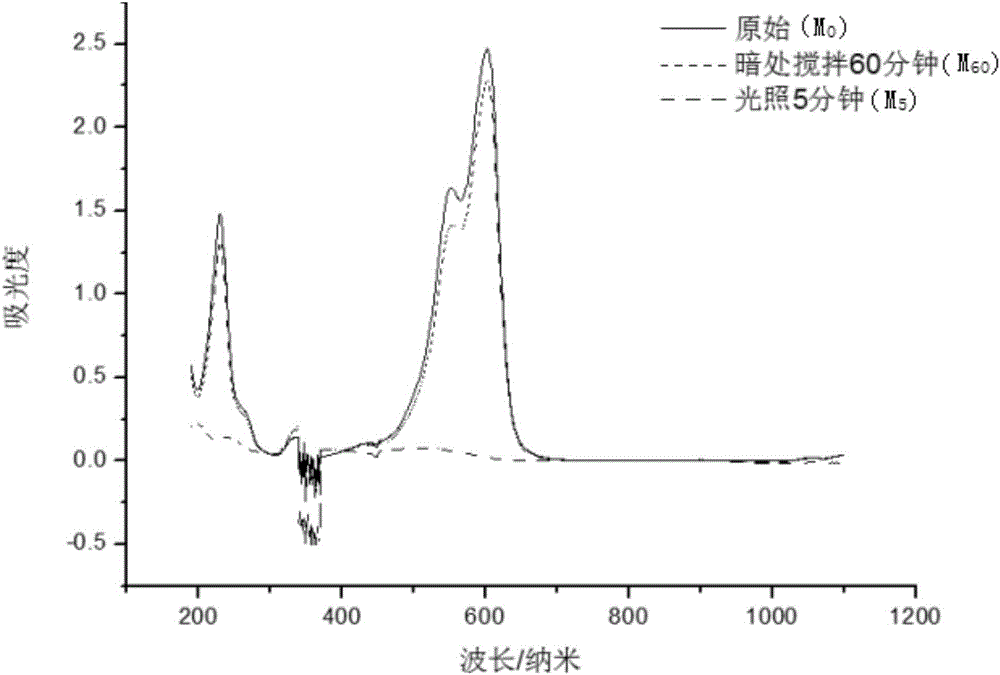

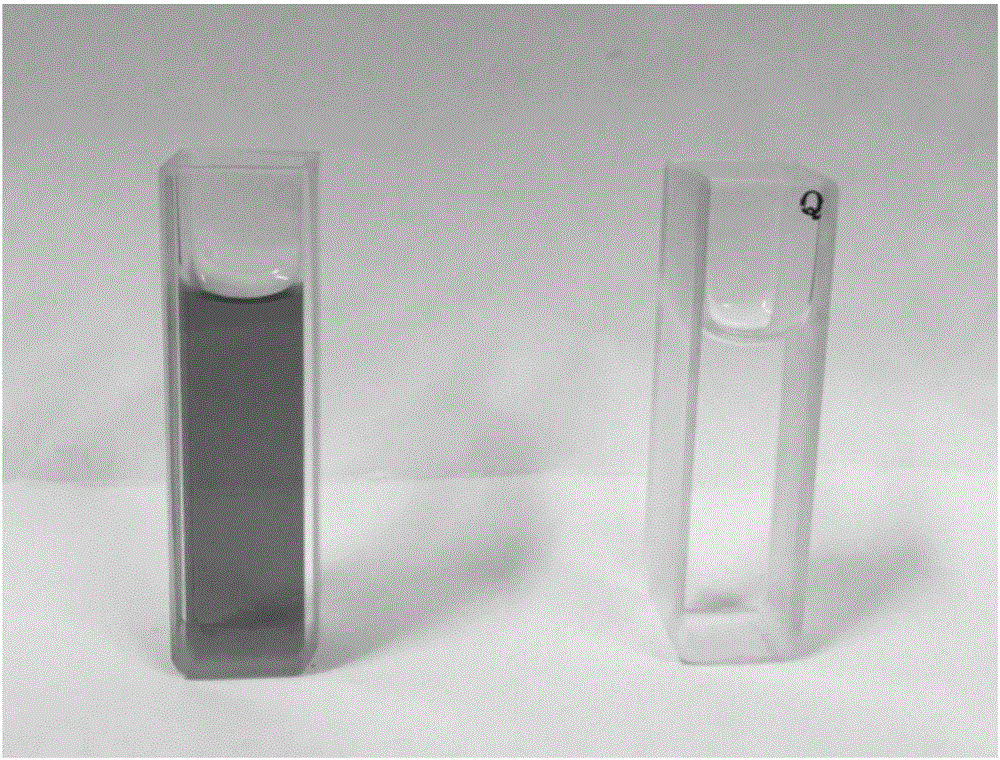

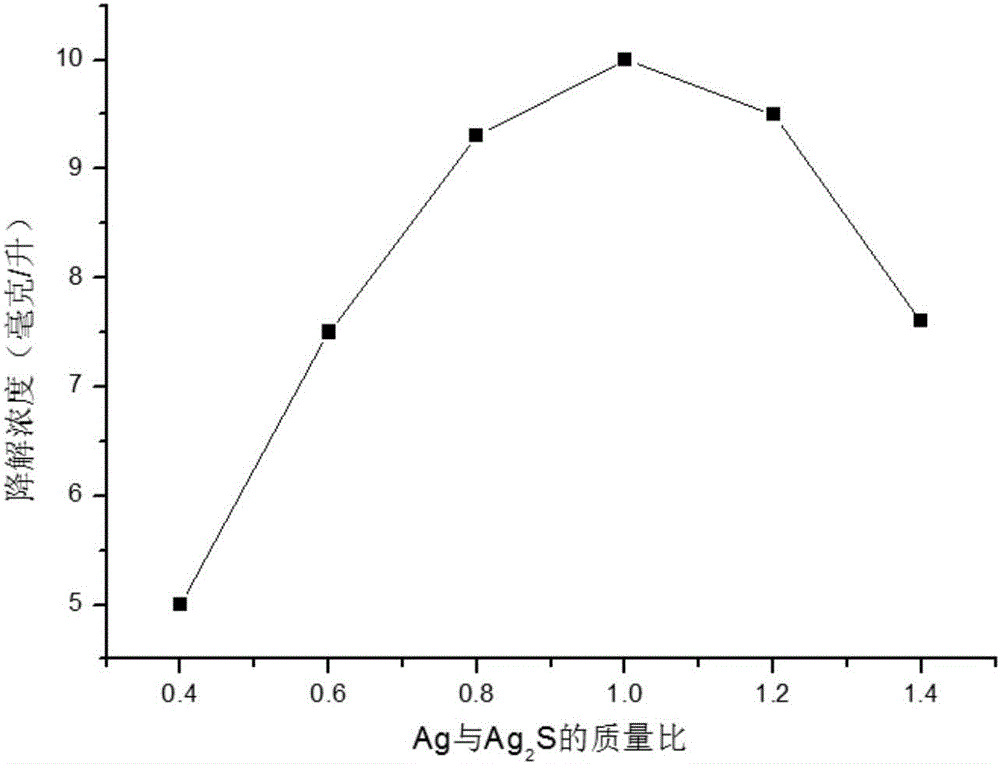

Preparation method of laser induced mono-disperse Ag-Ag2S nano-particle photocatalyst

InactiveCN106475038ASimple methodImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationMethyl blueLaser beams

The invention discloses a preparation method of a laser induced mono-disperse Ag-Ag2S nano-particle photocatalyst. The preparation method comprises the following steps: (1) adding an aqueous solution containing thioacetamide and hexadecyl trimethyl ammonium bromide into a rotary container as a reaction solution; (2) immerging a polished Ag sheet in the reaction solution, and performing rotation; (3) focusing laser beams on the Ag sheet in the rotary container by virtue of a quartz lens; and (4) taking the Ag sheet after laser radiation out of the rotary container, rinsing a product collected on the surface of the Ag sheet after laser radiation by using distilled water, performing centrifugation, and drying a deposited product to obtain the photocatalyst. The preparation method disclosed by the invention is simple, and the Ag-Ag2S nano-particle photocatalyst prepared by the method shows the superior performance of removing methyl blue (MB) in wastewater, and the MB removal rate within 5min in visible light can reach 99.83%; and after absorption and degradation of organic matters, settling separation of a nano material without external force is achieved.

Owner:TIANJIN UNIV

Sweet potato beverage and manufacturing method thereof

The invention provides a sweet potato beverage. The beverage consists of sweet potato beverage juice and anticoagulant, wherein the sweet potato beverage juice is filtrate which is prepared by mixing and fermenting sweet potato, amylase and water; and the anticoagulant is filtrate which is prepared by mixing and stirring fresh climbing fig, fresh giantarum, fresh yam and water. The manufacturing method of the sweet potato beverage comprises the following steps of: preparing the sweet potato beverage juice, preparing the anticoagulant and preparing the sweet potato beverage. Natural anticoagulant is added into the sweet potato beverage juice, a suspending hydrophilic group in a natural anticoagulant molecule inhibits generation of precipitates in the beverage, the problem that sand feel often occurs in the sweet potato beverage can be completely solved, so that the preservation period of the beverage is effectively prolonged, and the beverage tastes smoothly. The beverage has the advantages of reasonable component proportion, good taste and long preservation period, is easy to manufacture, and ensures that precipitate or dimixing cannot occur when the prepared beverage is stored for long time, and no sand feel exists when the beverage is drunk. The scale industrial production of the sweet potato beverage can be realized.

Owner:黎福根 +1

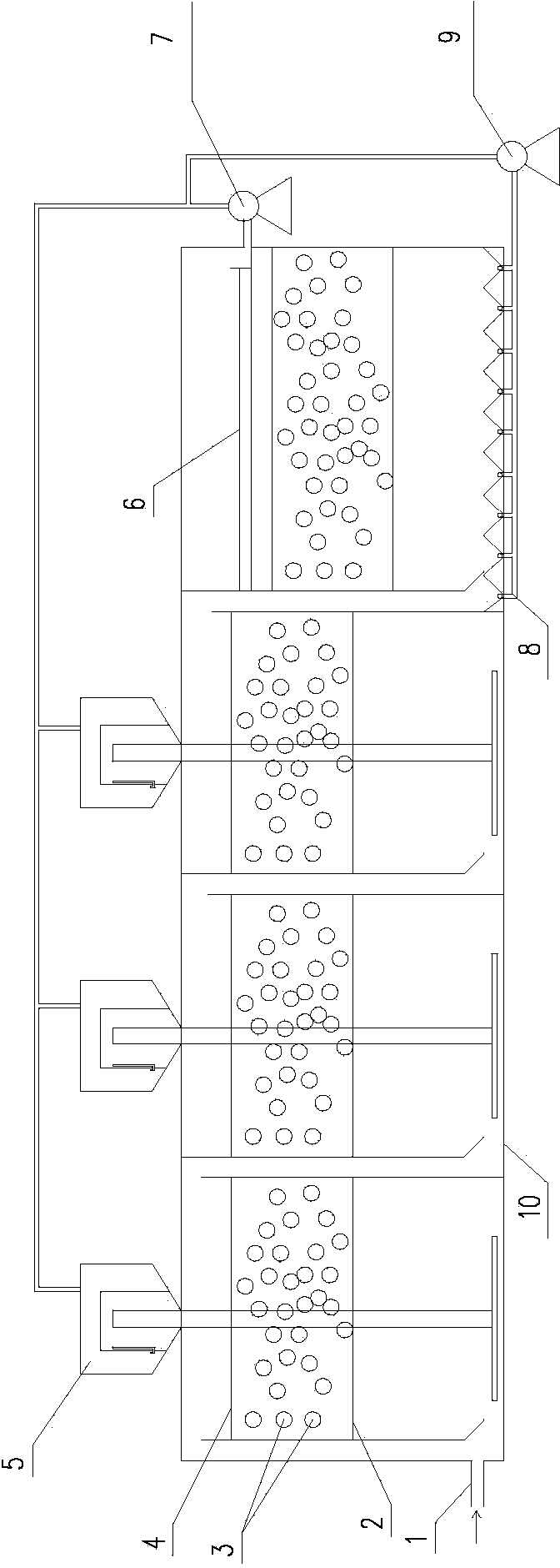

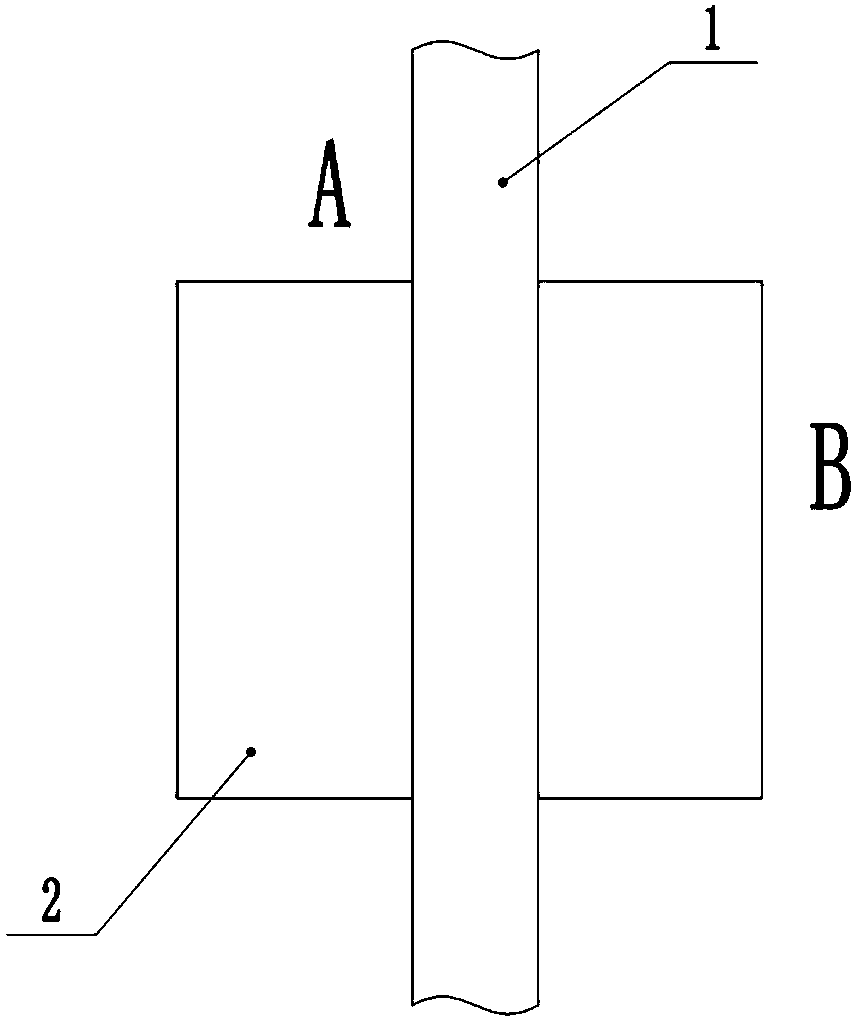

Novel efficient anaerobic bioreactor

ActiveCN103896397AIncreased shock load resistanceNo sedimentationTreatment with anaerobic digestion processesNuclear engineeringEngineering

The invention discloses a novel efficient anaerobic bioreactor which is characterized by comprising a reactor body (10), wherein a lateral inflow water distributor (1) is arranged on one side of the reactor body (10); a lower supporting bed (2) is arranged at the lower part of each baffled reactor in the reactor body (10); flowing biological stuffing layers (3) are formed between upper limiting layers (4) and lower supporting beds (2); a pulse water distributor (5) is arranged at the top of each baffled reactor in the reactor body (10); and the water outlet of an effluent weir (6) of the reactor is connected with the pulse water distributors (5) through a backflow water pump (7). The novel efficient anaerobic bioreactor has the advantages of convenience in running and maintenance, small maintenance amount and high processing capability. The hydraulic stirring in each reaction chamber can be changed by adjusting the water inflow of pulse water distribution in each reactor, so that a hydraulic environment needed by each stage of reaction of an anaerobic reaction can be better created.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

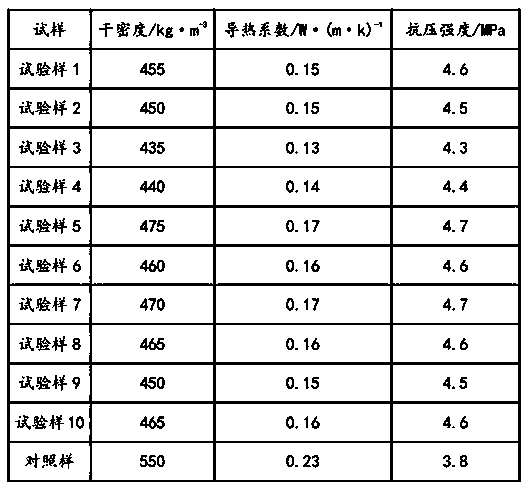

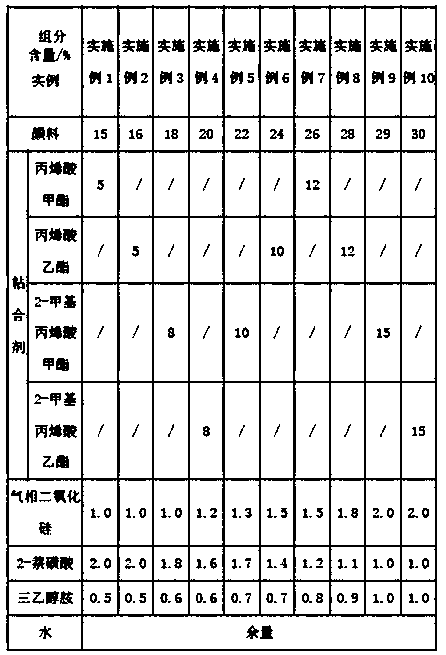

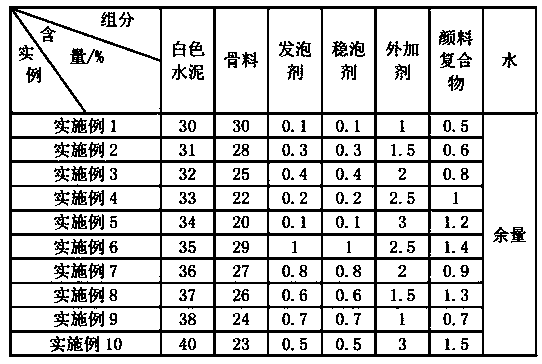

Colorful foam concrete

ActiveCN108640600AImprove color fixation effectGood light fastnessCeramicwareFoam concreteFoaming agent

The invention discloses a colorful foam concrete, relates to the field of concrete and aims to solve the problem that in the prior art, coloring is performed with a coloring base material attached tothe surface of a concrete base material, the coloring effect is poor, and mottling, color change or even color stripping likely appears. According to the technical scheme, the colorful foam concrete is characterized by being prepared from, by mass, 30%-40% of white cement, 20%-30% of aggregate, 0.1%-1% of foaming agent, 0.1%-1% of foam stabilizer, 1%-3% of additive, 0.5%-1.5% of pigment compound and the balance water. The colorful foam concrete has the advantages of being bright in color, lasting in color fixation and convenient to construct.

Owner:成都建工预筑科技有限公司

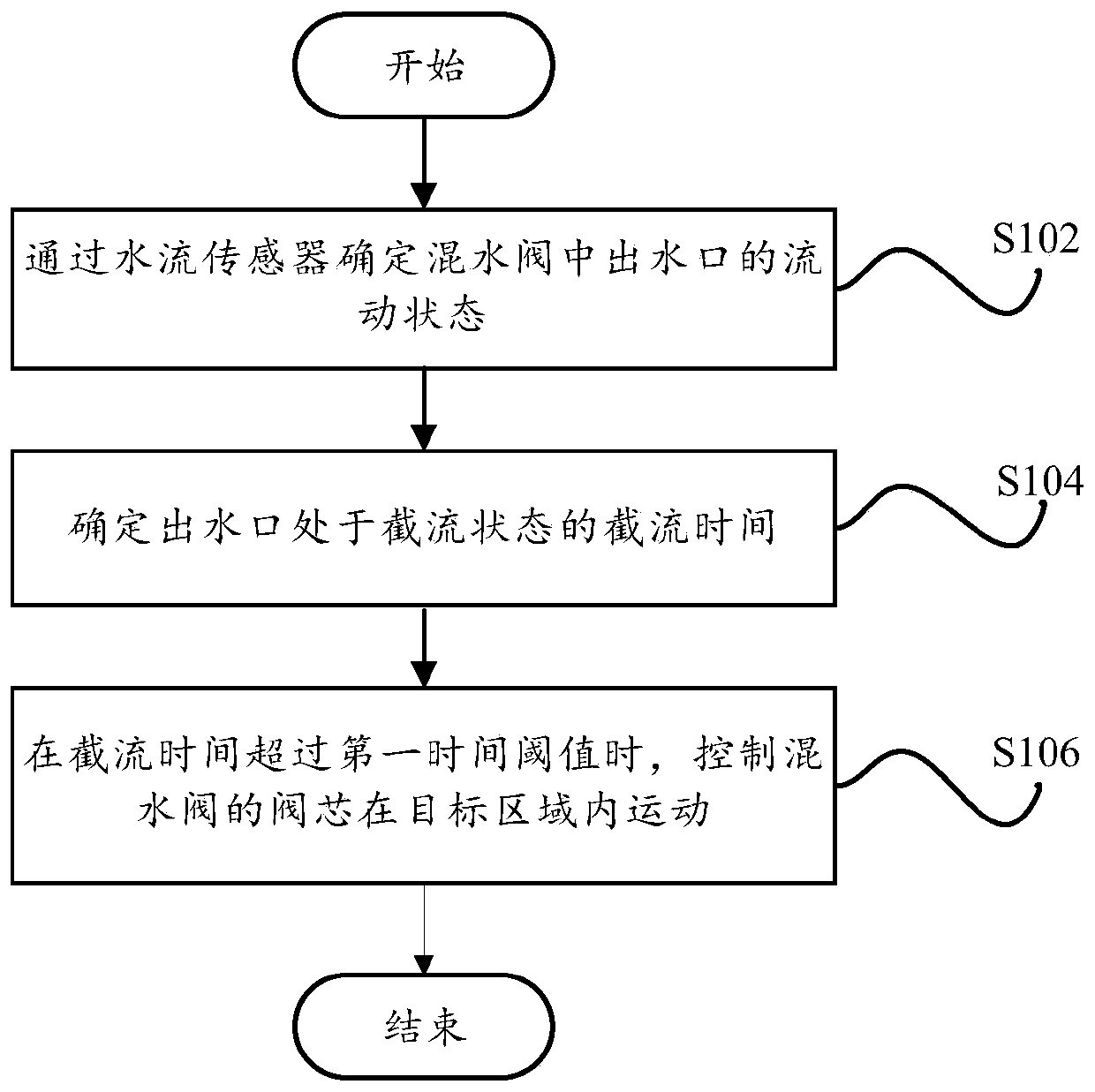

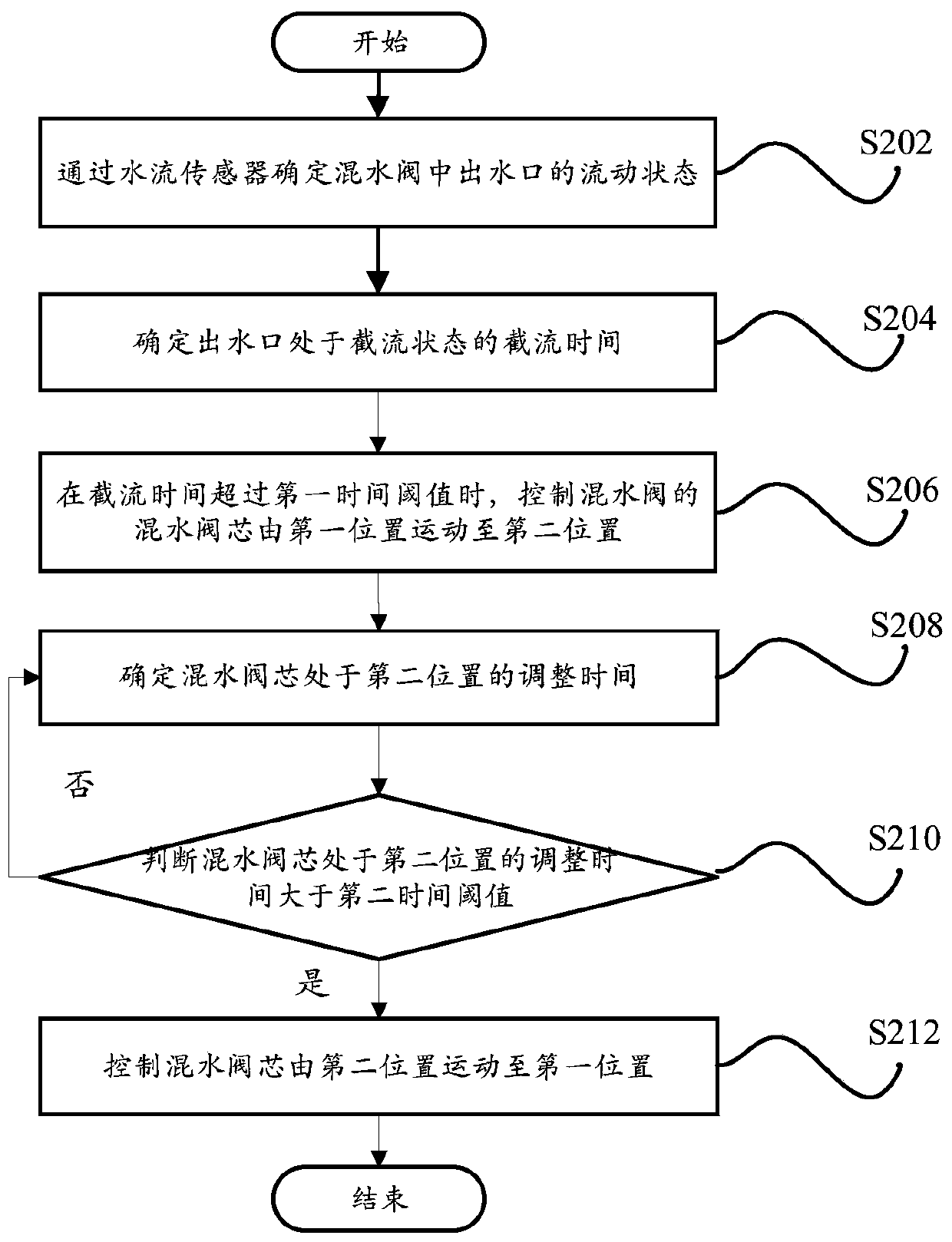

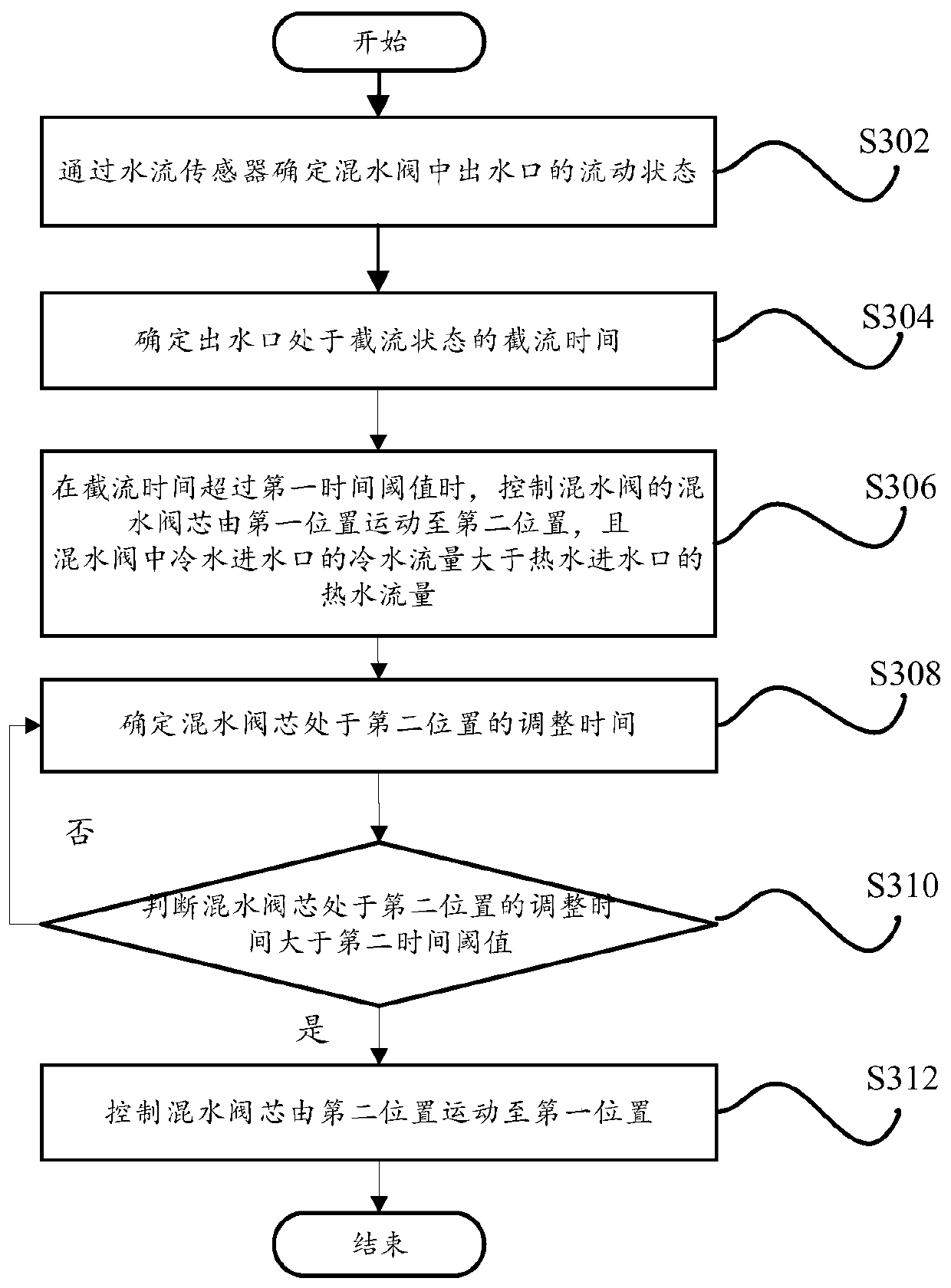

Valve core control method, water mixing valve and computer readable storage medium

ActiveCN110081206AReduce or prevent buildupNo need to change its structureOperating means/releasing devices for valvesMultiple way valvesWater flowEngineering

The invention provides a valve core control method, a water mixing valve and a computer readable storage medium. The valve core control method comprises the following steps that a flowing state of a water outlet in the water mixing valve is determined through a water flow sensor; intercepting time when the water outlet is in an intercepting state is determined; and a water mixing valve core of thewater mixing valve is controlled to move in a target area when the intercepting time exceeds a first time threshold value. According to the technical scheme, hot water of a hot water inlet can be guided to generate convection with cold water of a cold water inlet, so that dirt accumulation of the water mixing valve core can be reduced or prevented; and meanwhile, the water mixing valve core can also stir originally static water nearby through automatic moving, so that the phenomenon that dirt maintains in a static state for a long time and therefore precipitates and accumulates is avoided.

Owner:HEFEI MIDEA HEATING & VENTILATING EQUIP +1

High-efficiency environment-friendly energy-saving mixed fuel gas

The invention provides a high-efficiency environment-friendly energy-saving mixed fuel gas. The fuel gas is prepared by mixing the following substances by weight: 70 to 80 parts of liquefied petroleum gas, 15 to 20 parts of dimethyl ether, 1 to 5 parts of methanol and 5 to 10 parts of ethanol. Liquefied petroleum gas mainly contains propane and includes many substances, so a certain amount of ethanol should be added as a solvent to realize solvation and azeotropy; ethanol contains oxygen, has good combustibility and is a solvent, and a certain amount of methanol is added to supplement oxygen; thus, oxygen content in liquefied petroleum gas is increased, which is beneficial for combustion. Emission during combustion is reduced by 40%; thermal efficiency is increased by more than 20%; the volume of methanol and dimethyl ether is 3%; complex substances in liquefied petroleum gas are fused by ethanol into dimethyl ether and methanol, then an obtained mixture is dissolved in liquefied petroleum gas, no deposition and layering occur, and no corrosion is posed.

Owner:HEBI BAOFA ENERGY SCI & TECH

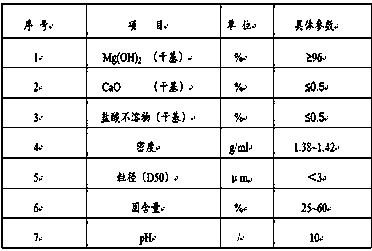

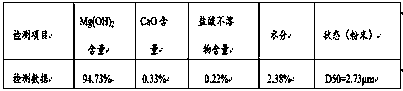

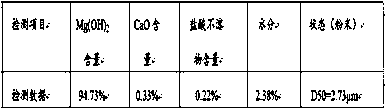

Production process and application of magnesium hydroxide suspension with high solid content

ActiveCN111453749AEasy to operateShort preparation timeGas treatmentTransportation and packagingEmission standardSlurry

The invention provides a production process of a magnesium hydroxide suspension with high solid content. The production process comprises a crushing step and a pulping and blending step. The inventionalso provides application of the magnesium hydroxide suspension with high solid content. The magnesium hydroxide suspension is used for treatment of flue gas discharged by ships. The invention has the beneficial effects that the magnesium hydroxide suspension is good in suspension performance, low in viscosity and stable and uniform in quality, and has a viscosity in a range of 139.8 mPa.s to 1571.2 mPa.s; under the condition of standing for 7 days, the solid content change of slurry at an upper layer, a middle layer and a lower layer of the suspension is not more than 1.8%, the maximum solidcontent difference among all layers is not more than 2.45%, and the phenomena of deposition and scaling at the bottom of a container are avoided; when the magnesium hydroxide suspension is used for desulfurization of ship flue gas, good desulfurization effect is obtained, and the strictest emission standard requirements on sulfur oxide in ship flue gas can be met; i.e., the emission effects thatan S / C value in ship exhaust gas detection is less than 4.3 and the S content in fuel oil is less than 0.1% are achieved.

Owner:山东格润德环保科技有限公司

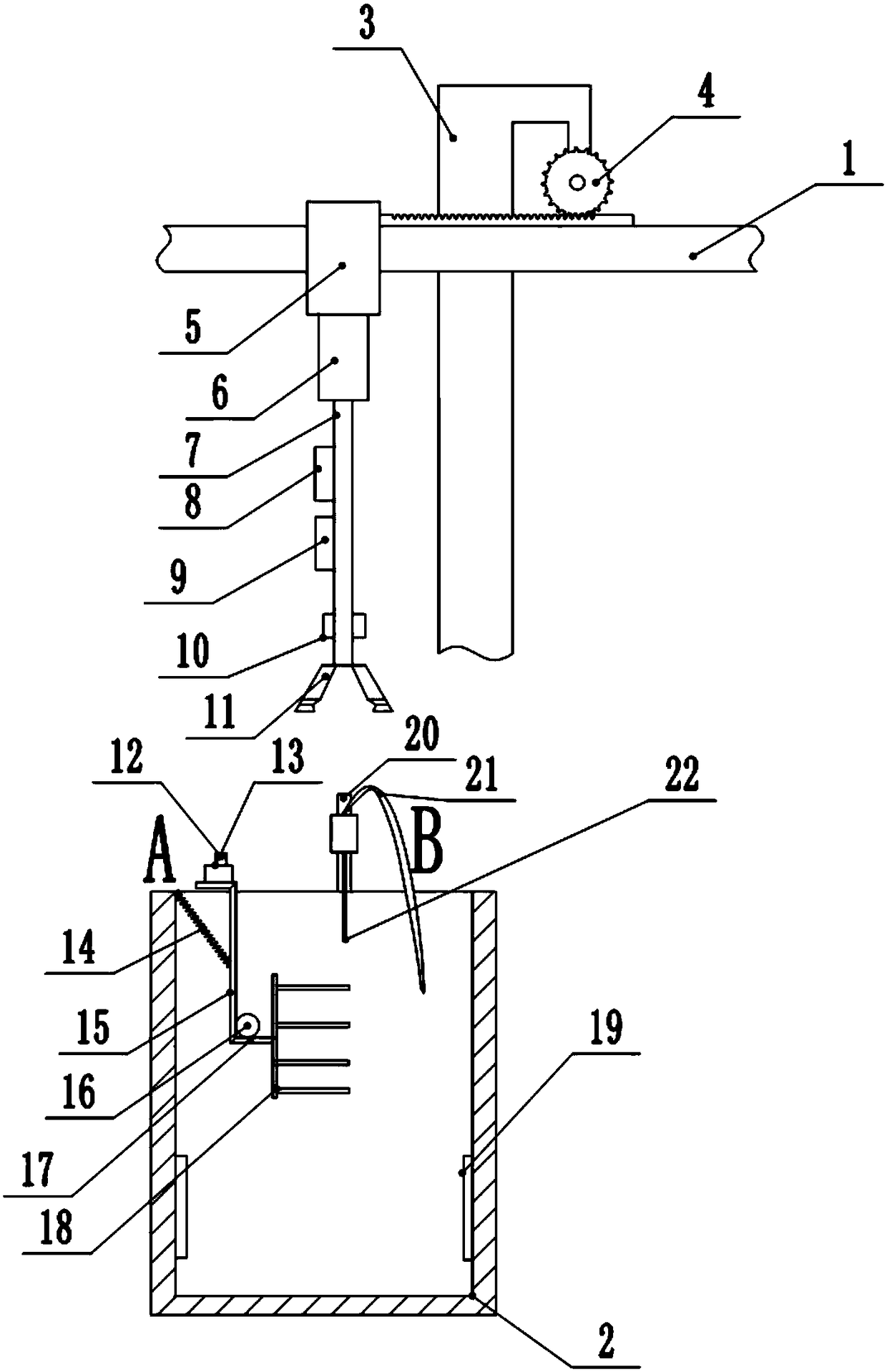

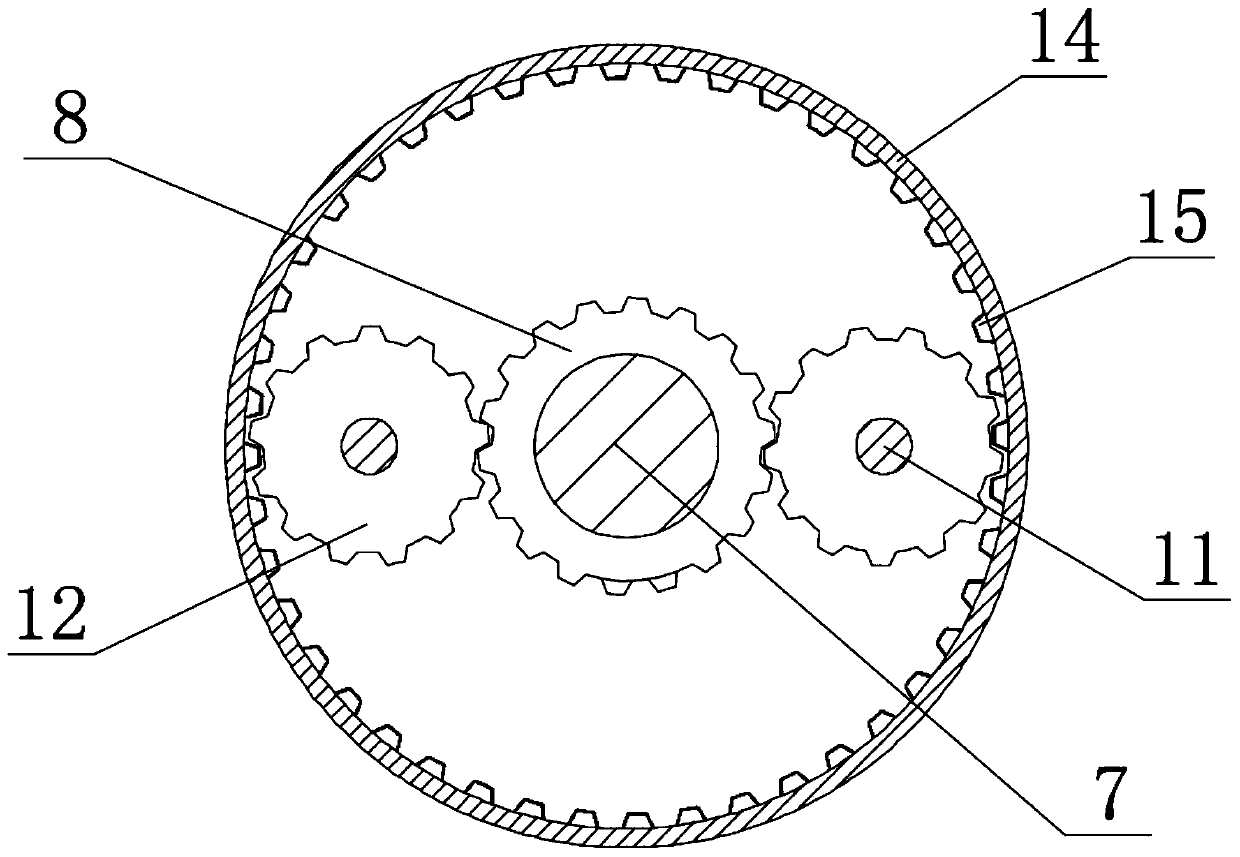

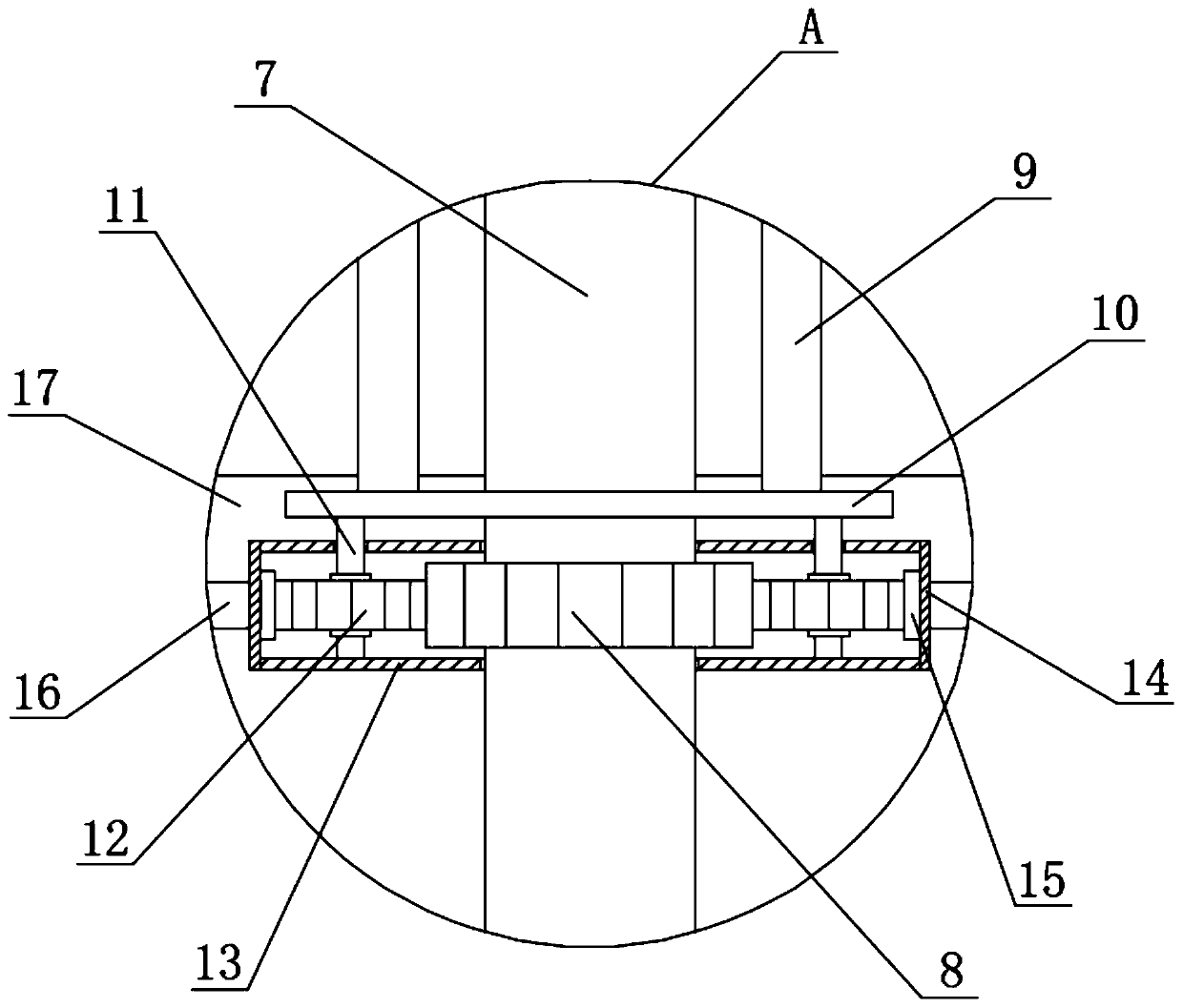

Oil immersion device for gears

ActiveCN108525938ARealize mechanized controlImprove work efficiencyLiquid surface applicatorsCoatingsGear wheelFuel tank

The invention relates to the technical field of gear machining, in particular to an oil immersion device for gears. The oil immersion device comprises a support, a power mechanism, a mechanical arm and an oil immersion tank and is characterized in that a rack conveying rack for conveying the mechanical arm and a gear meshing with the rack conveying rack are connected to the support, the mechanicalarm sequentially comprise an air cylinder, an air pressure rod and a mechanical gripper, the mechanical arm is detachably connected with a connecting block through the air cylinder, the air pressurerod is provided with a first magnet and a second magnet, a heating part for heating immersion oil is mounted in the oil immersion tank, a rotary shaft is rotatably mounted in the middle of the inner lateral side of the oil immersion tank, a first rotary rod is movably vertically mounted at one end of the rotary shaft, and a second rotary rod is movably horizontally mounted at the other end of therotary shaft. By the oil immersion device, the problems that the immersion oil in the middle of the oil immersion tank cannot be heated, the immersion oil is unevenly heated, the immersion oil in themiddle of the oil immersion tank cannot be completely dissolved, and the oil immersion effect of the gears is affected are solved.

Owner:重庆新锐科技服务有限公司

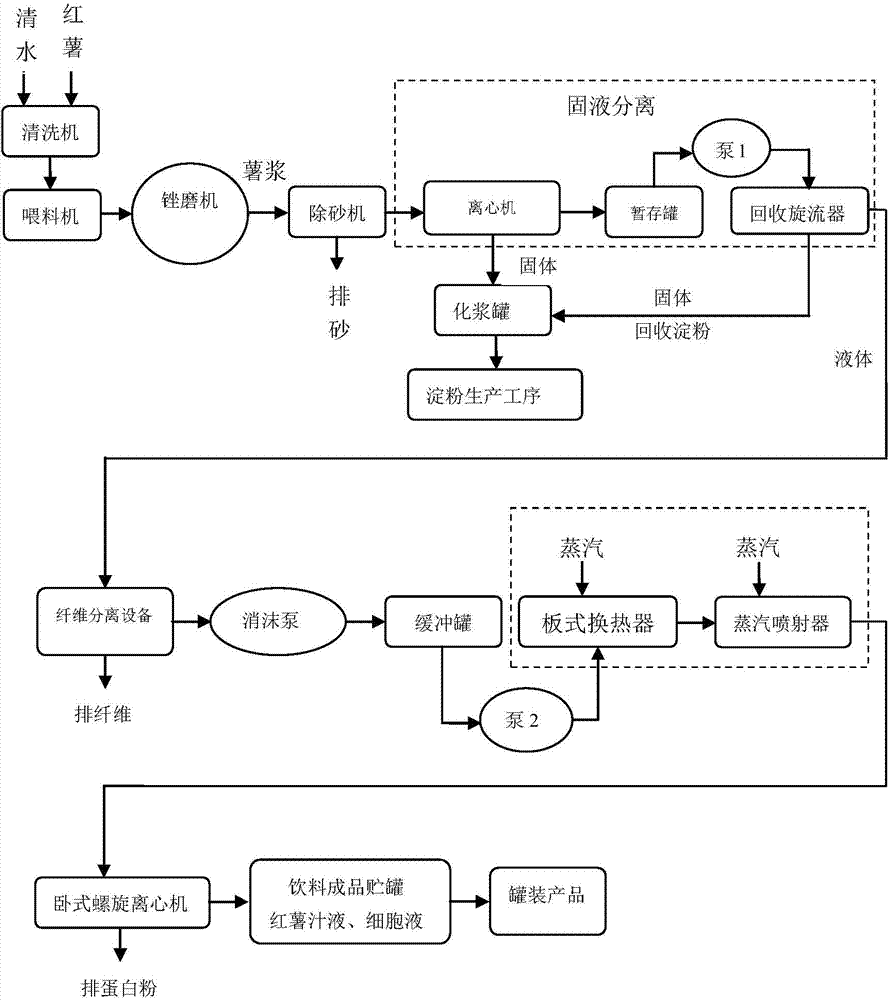

Preparation method of potato type juice and cell sap beverage

The invention provides a preparation method of potato type juice and a cell sap beverage. The preparation method comprises the following steps: crushing potatoes evenly in a rasping machine and breaking cell membranes of the potatoes to release cell sap; removing fine sand grains by a sand remover; separating solids from liquid in the pulp, sending the separated solids into a pulping tank for pulping, and entering the starch production working procedure; sending the separated liquid into a fiber separating device, and removing potato fibers out of the potato type juice and cell sap by the fiber separating device; removing protein out of the liquid in a hot flocculation combining mode; and acquiring a potato type juice and cell sap finished product so as to prepare the true potato type beverage. A physical method is adopted in the whole production without adding any additive, so that the potato type juice and cell sap beverage is relatively safe to take; different constituents of the potatoes are classified and extracted so as to prepare different products; the pollution is reduced, and the product value is enhanced.

Owner:SHANGHAI FUSHEN IND & TRADE CO LTD

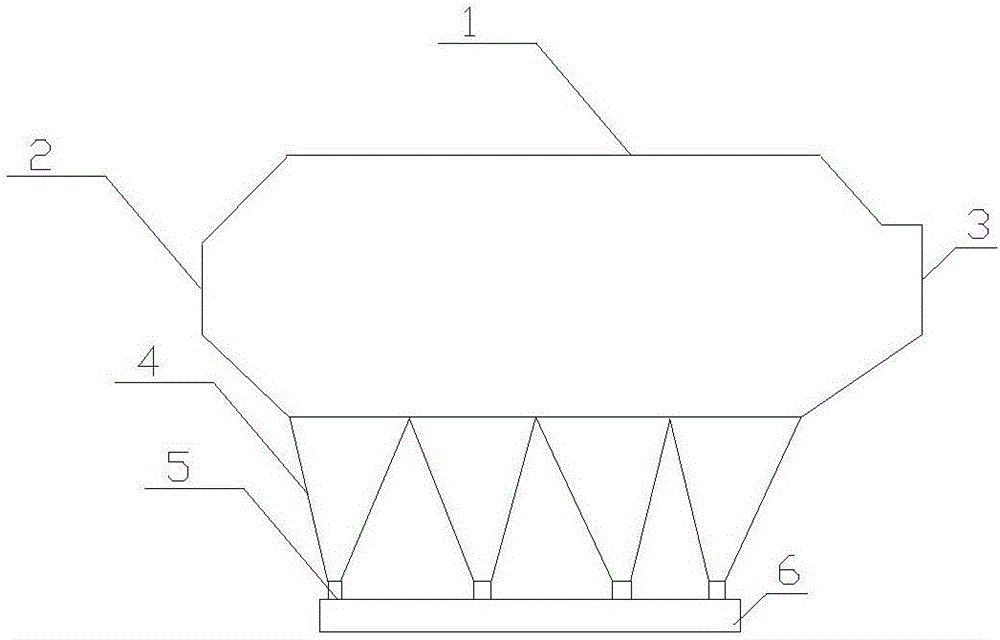

Novel electric dust remover

InactiveCN106238208AUnobstructed airflowNo dust accumulationElectrostatic separation detailsAirflowEngineering

The invention provides a novel electric dust remover and relates to the field of environmental protection equipment. The novel electric dust remover comprises a dust remover shell body. One end of the dust remover shell body is provided with an air inlet, and the other end of the dust remover shell body is provided with an air outlet. The lower end of the dust remover shell body is further provided with at least two dust storage hoppers. The air outlet of the dust remover shell body is further provided with a filter screen. The filter screen is further arranged at the air outlet of the dust remover shell body, thus, smooth airflow can be ensured, and the dust deposition phenomenon is avoided. The novel electric dust remover is low in improvement cost and can be widely applied to the technical field of environmental protection equipment.

Owner:扬州天泓科技实业有限公司

Polishing liquid for hard disk recording heads and preparation method thereof

InactiveCN103897608AImprove suspension stabilityImprove dispersion uniformityPolishing compositions with abrasivesHydrocarbon solventsActive agent

The invention discloses a polishing liquid for hard disk recording heads, which comprises the following components in parts by weight: 1-3 parts of nanoscale diamond powder, 0.5-4 parts of a FA / O non-ionic surfactant, 0.5-5 parts of a FA / O chelating agent, 90-150 parts of a hydrocarbon solvent, 0.3-2 parts of an oxidizing agent, and 0.2-0.5 part of a corrosion inhibitor. Products of the invention are applied to the polishing process of hard disk recording heads, and detections show that both the surface quality and performance of hard disk recording heads accord with the requirements on the polishing quality of recording heads, the polishing efficiency is high, the quality is good, and no failure phenomenon occurs.

Owner:杨飏 +1

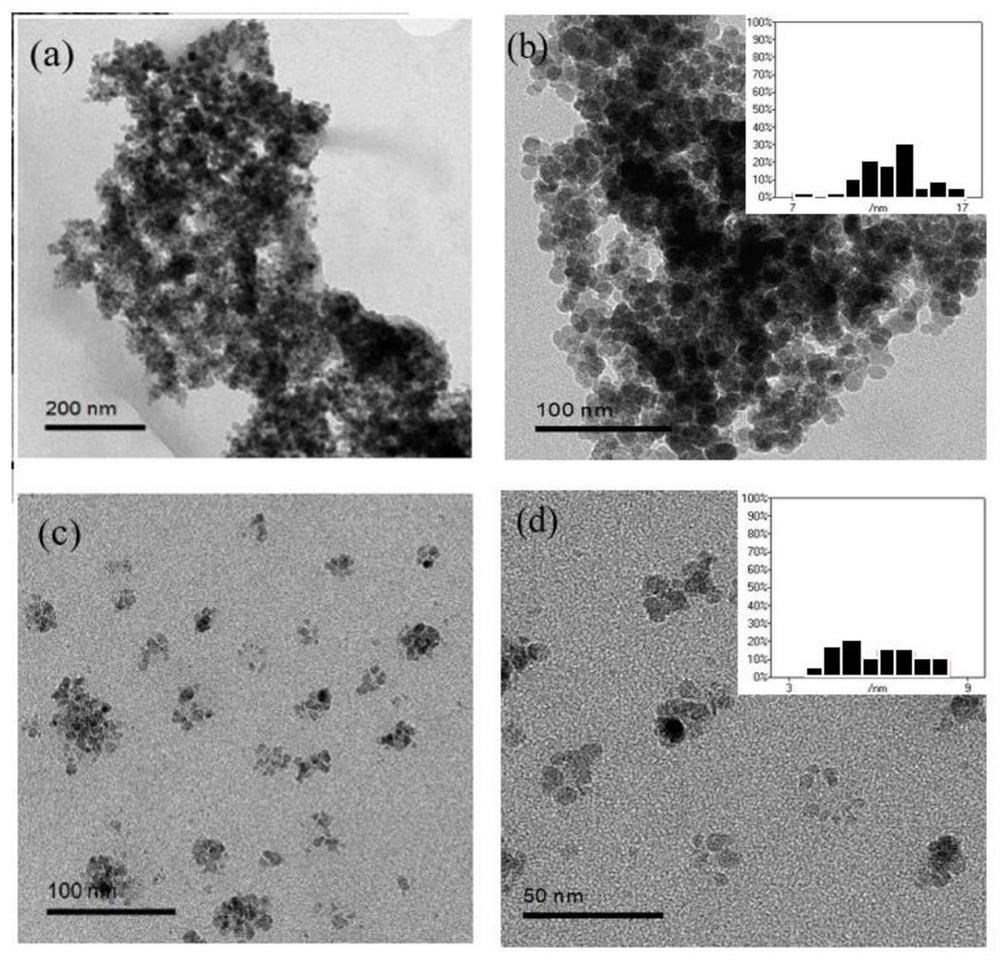

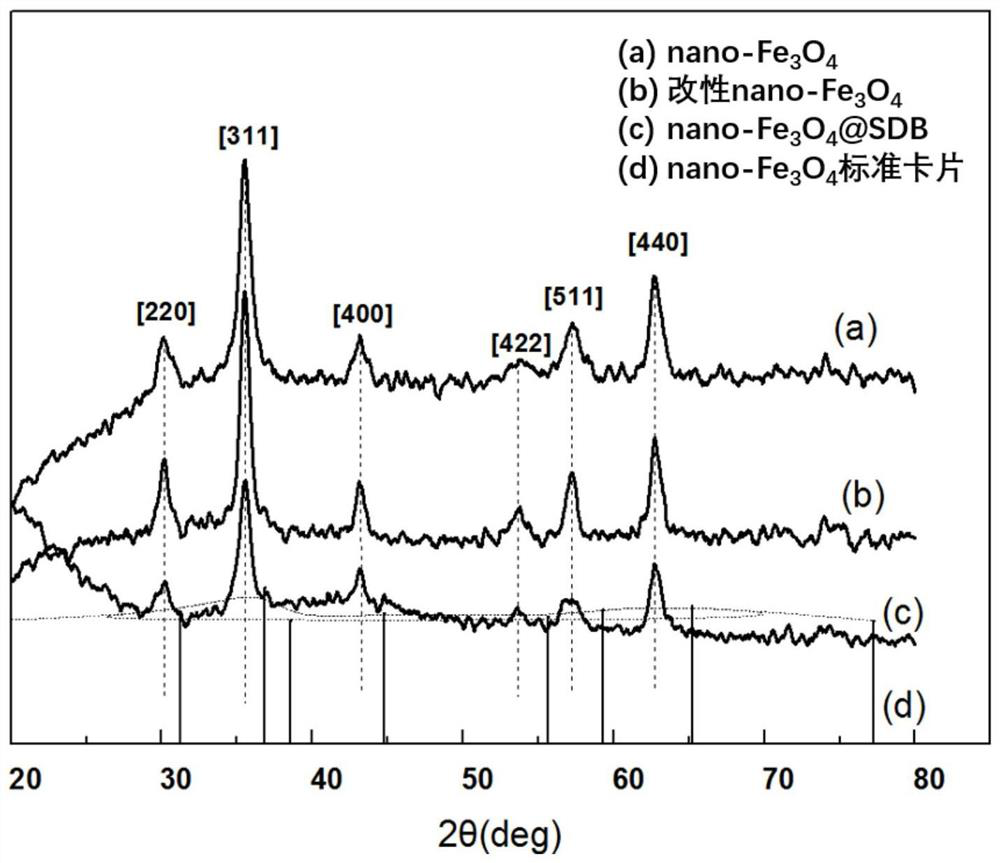

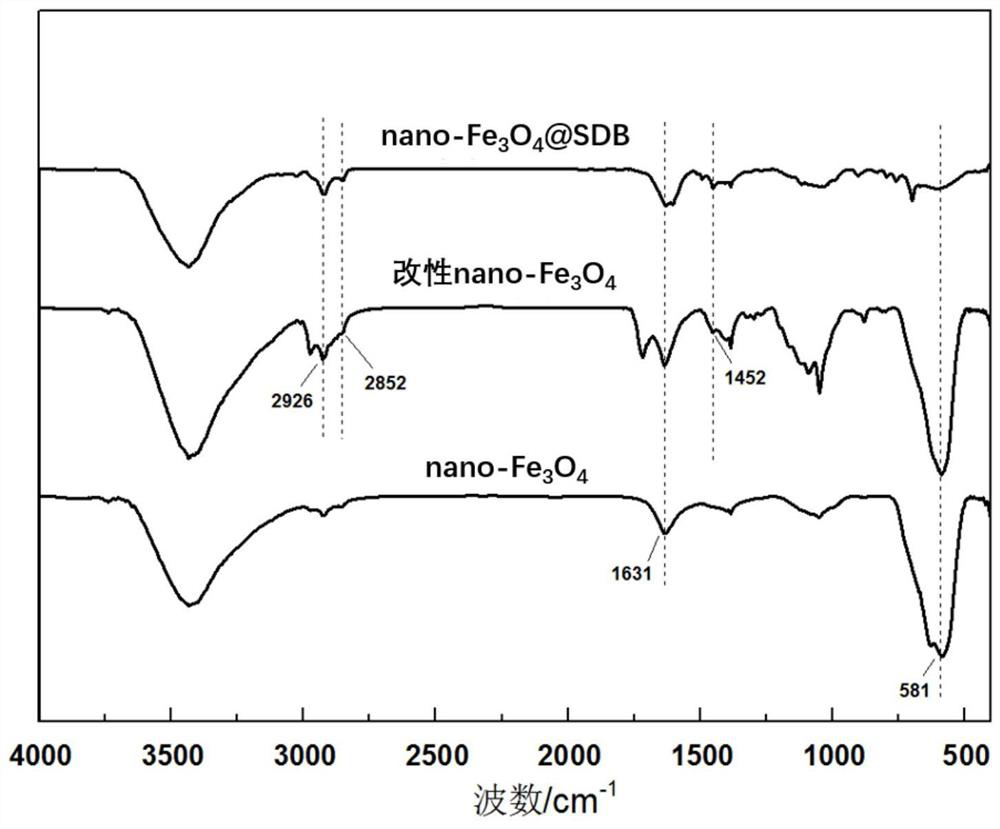

Preparation method of nano ferric oxide doped styrene-divinylbenzene copolymer hydrophobic catalyst carrier

ActiveCN107973872BIncreased dispersionEvenly dispersedCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsBenzoyl peroxidePtru catalyst

Owner:SOUTHWEAT UNIV OF SCI & TECH

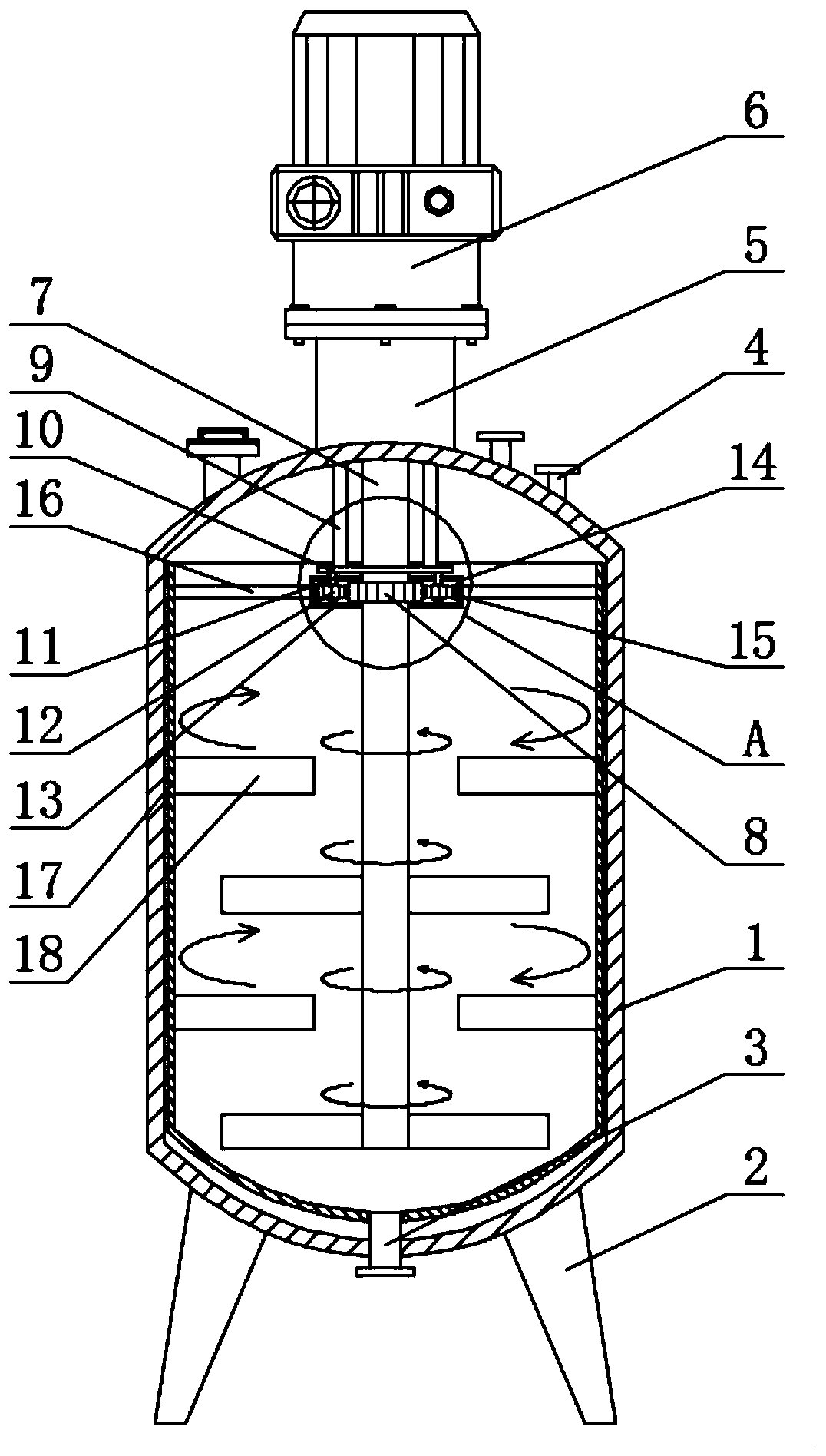

Batching device for waterproof material construction

InactiveCN110639402AImprove mixing efficiencyImprove the mixing effectRotating receptacle mixersTransportation and packagingElectric machineryManufacturing engineering

The invention relates to the technical field of waterproof material batching equipment, and further discloses a batching device for waterproof material construction. The batching device comprises a tank body; supporting legs are fixedly mounted at the bottom of the tank body; a discharge port is fixedly formed in the center of the bottom of the tank body. According to the batching device for waterproof material construction, a rotatable inner container is arranged in the inner wall of the tank body, and a traditional mode of mixing raw materials on the inner wall is changed; all the raw materials are put into the inner container, the inner container and a stirring shaft share a same motor, and the inner container rotates through a transmission structure, so the inner container can also rotate along with stirring blades while the stirring blades rotate, the inner container and the stirring blades rotate simultaneously to mix materials, the mixing efficiency in unit time can be improved,the mixing effect in the unit period is also improved, meanwhile, raw materials at the bottom of the inner container are prevented from settling and accumulating, and the quality of finished waterproof materials is guaranteed while the utilization rate of the raw materials is guaranteed.

Owner:湖南古圣砖瓦科技有限公司

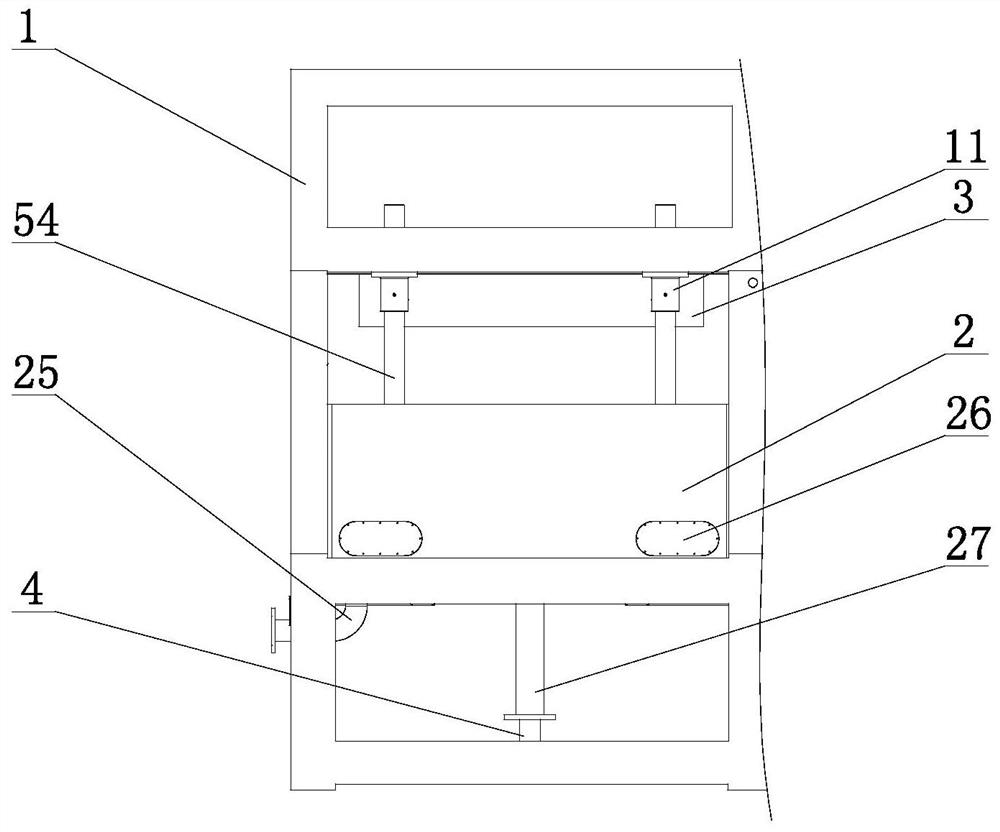

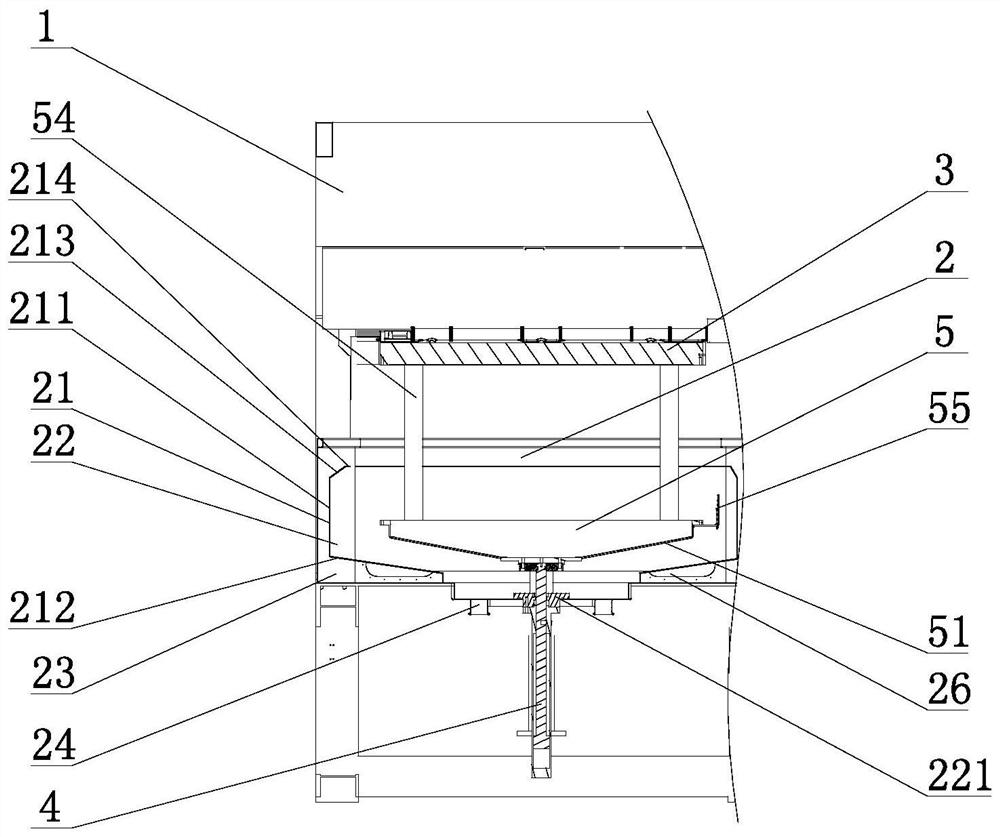

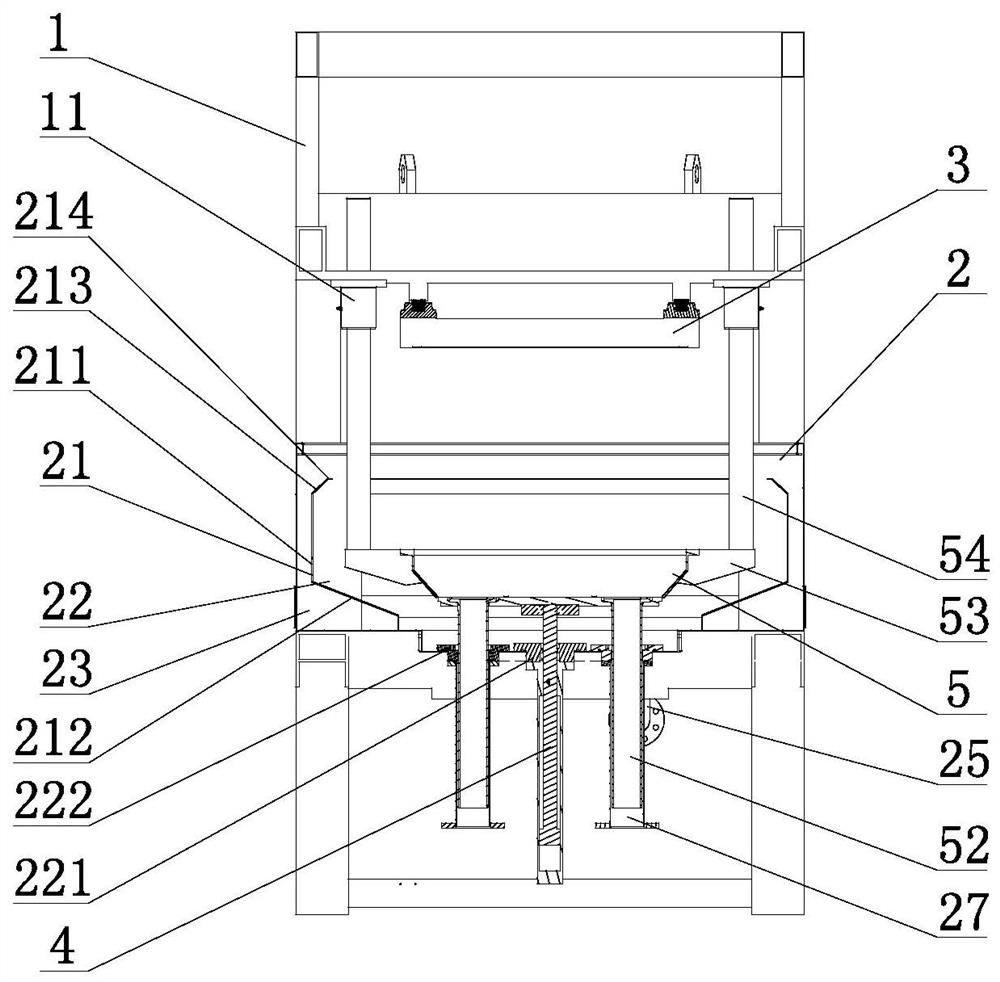

Forming mechanism of paper pulp molding equipment

PendingCN111608025AUniform concentrationNo sedimentationTextiles and paperMolded pulpMolding machine

The invention relates to a forming mechanism of paper pulp molding equipment. The forming mechanismcomprises a machine frame, wherein the machine frame is connected with a paper pulp tank; the machineframe is positioned above the paper pulp tank and is connected with an upper die; the interior of the paper pulp tank is divided into an inner cavity and an outer cavity through a partition plate. The inner cavity is connected with a slurry inlet pipe; the outer cavity is connected with an overflow pipe; the partition plate comprises a vertical section; the lower end of the vertical section is connected with a lower inclined section which is inclined downwards; the lower inclined section inclines towards the center of the paper pulp tank; the machine frame is located on the lower side of theinner cavity of the paper pulp tank and connected with a lifting driving part; the driving end of the lifting driving part extends into the inner cavity of the paper pulp tank and is connected with aforming lower die; the lower side of theforming lower die is provided with a lower inclined surface mathed with the lower incline section of the partition plate; the lower side of the forming lower die is connected with a pulp suction pipe; the pulp suction pipe passes through the paper pulp tank and extend to the lower side of the paper pulp tank. According to the forming mechanism of the paper pulp molding equipment, paper pulp concentration is uniform and sufficient, and nopulp accumulation and overflow splashing is caused.

Owner:弼伽机械科技无锡有限公司

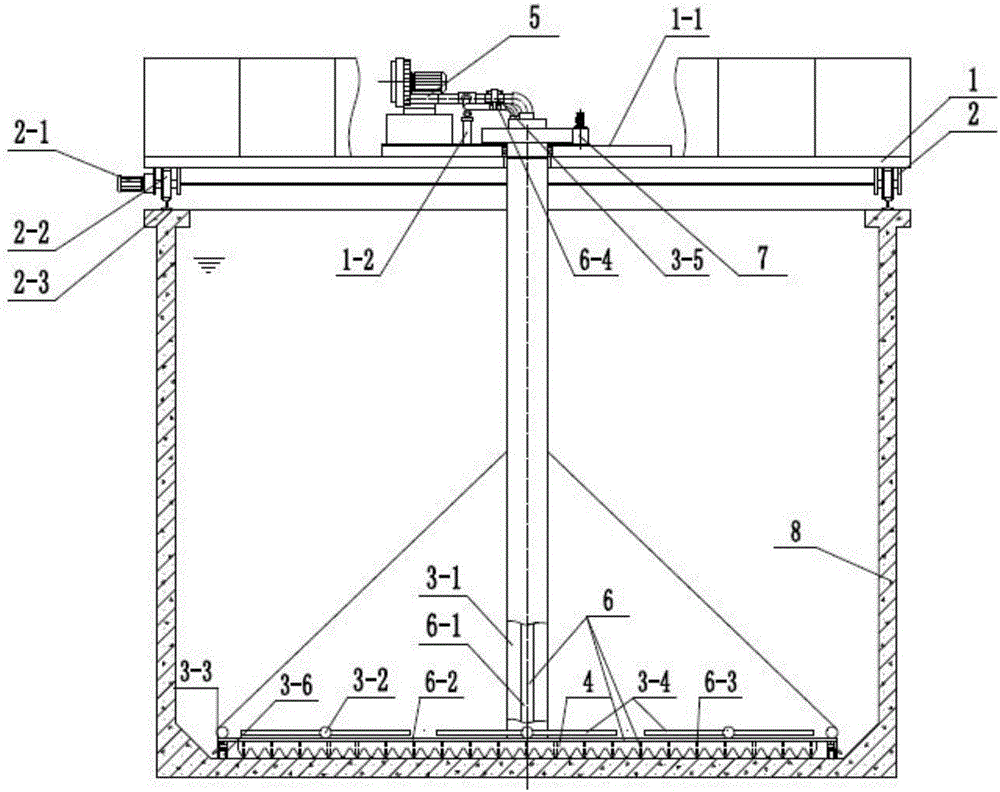

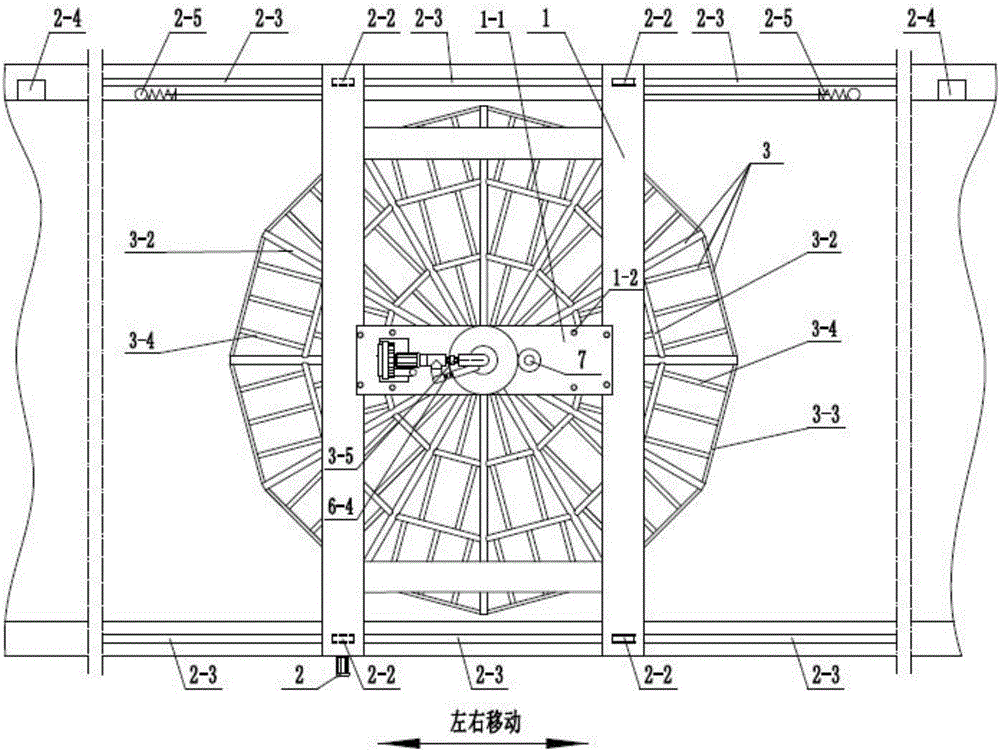

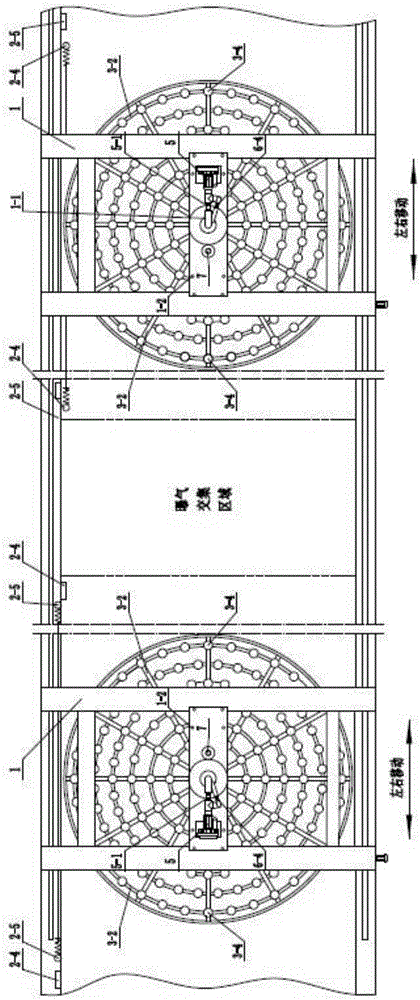

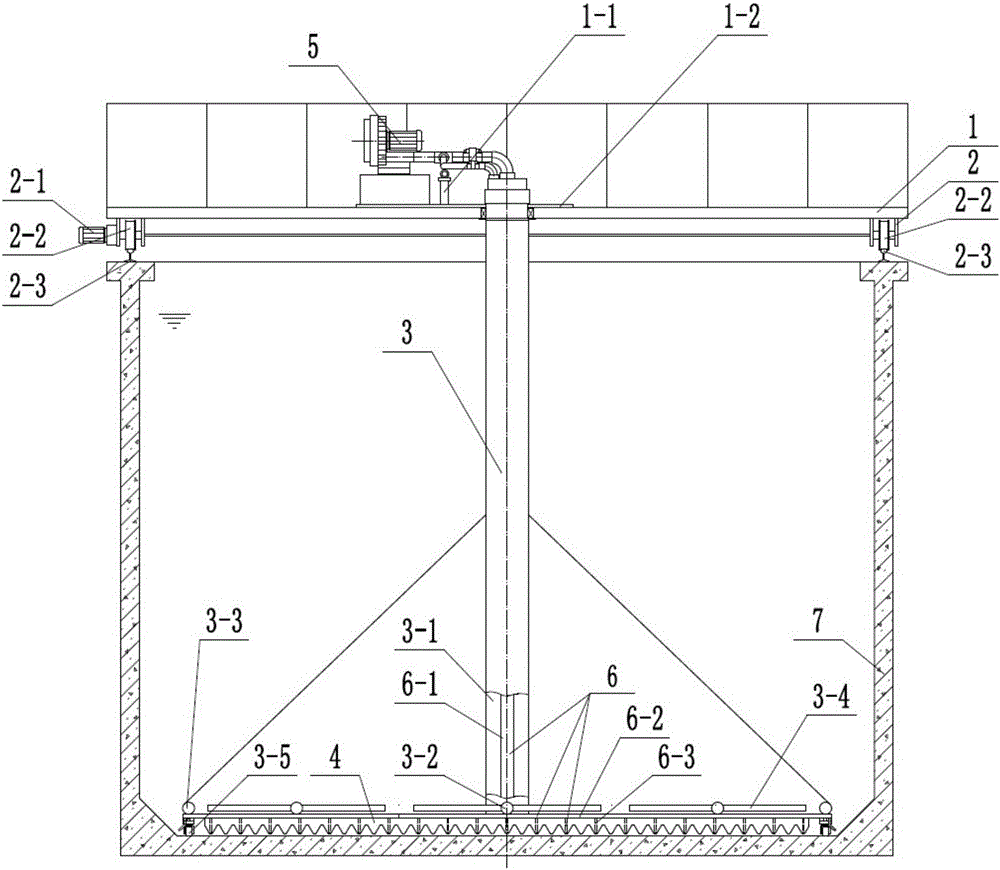

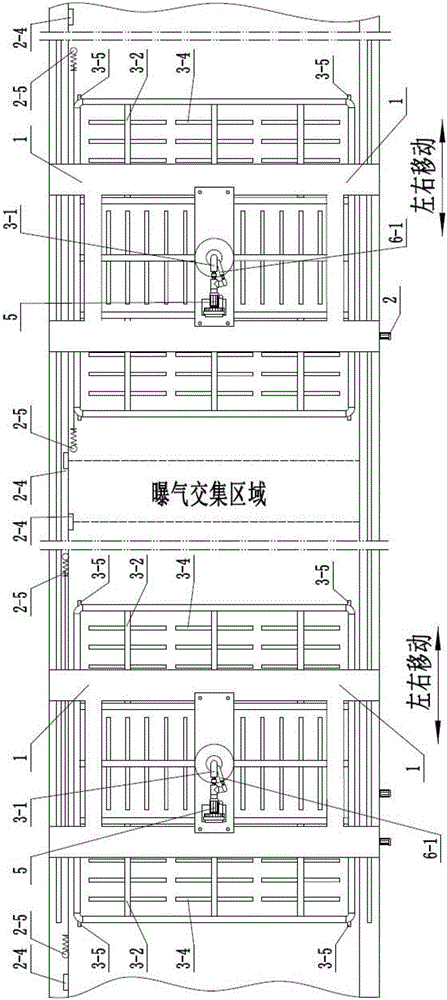

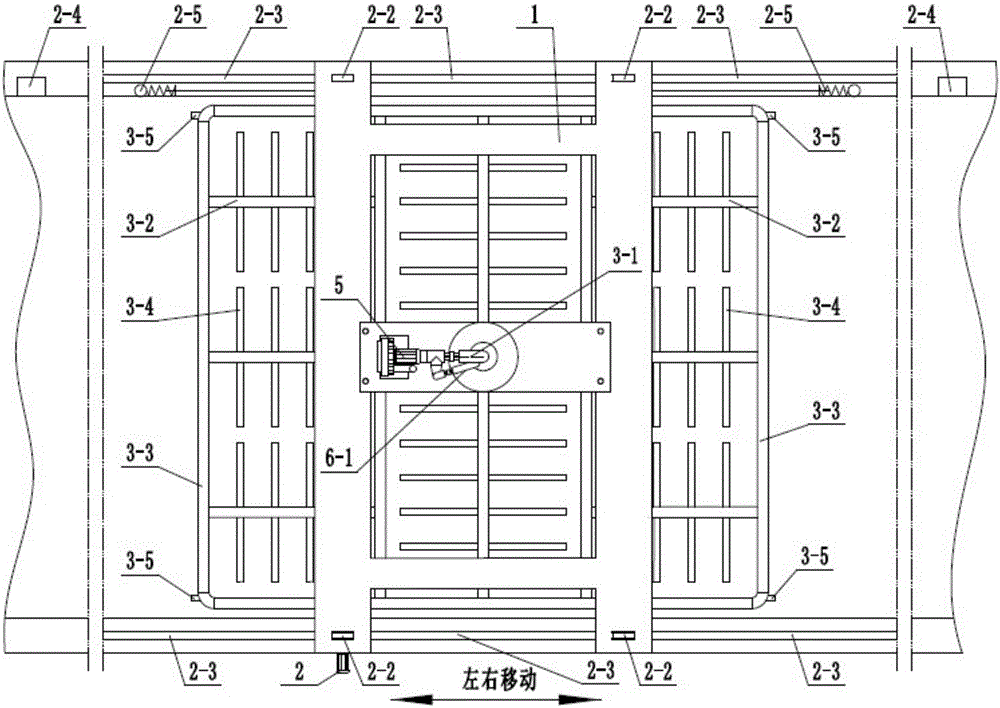

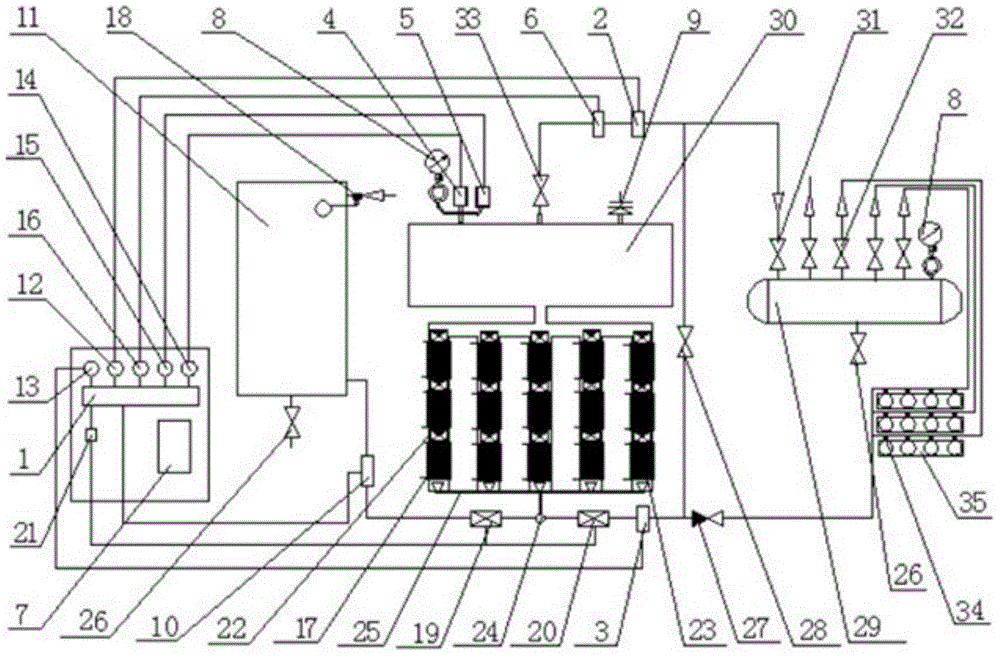

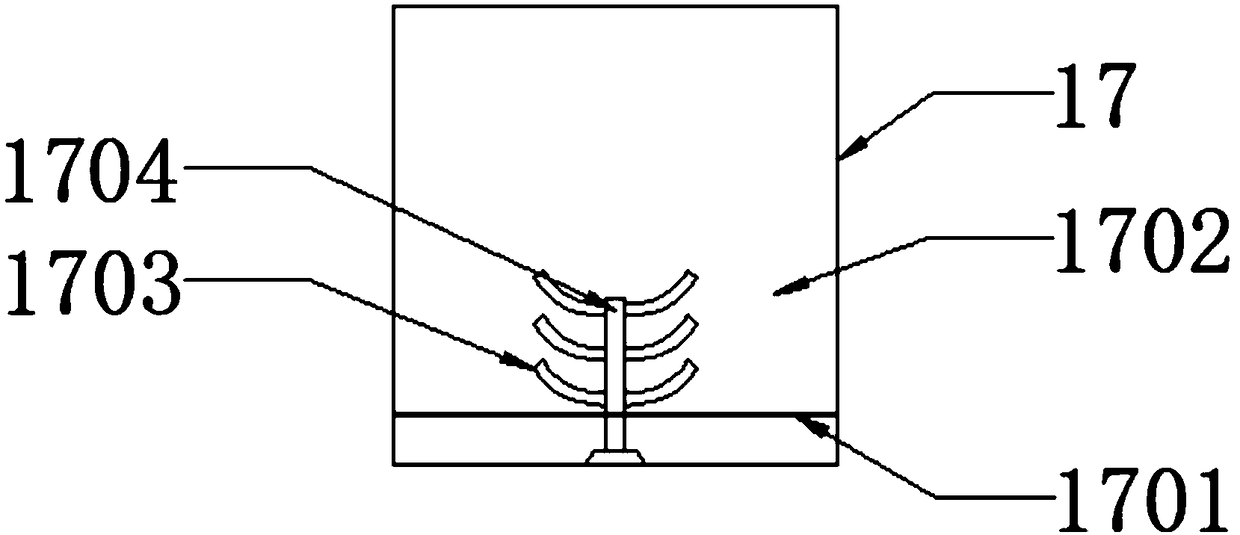

Reciprocation mobile bottom-layer aeration system and aeration method thereof

PendingCN106830299AExtend the mixing timeImprove oxygen transfer efficiencyWater treatment parameter controlSpecific water treatment objectivesAeration systemRadiation

The invention provides a reciprocation mobile bottom-layer aeration system and an aeration method thereof. The reciprocation mobile bottom-layer aeration system comprises a truss, a truss moving unit, aeration components, a scraper, a fan and a blowing unit, wherein the truss spans on an oxidation channel; the truss moving unit comprises a guide track, truss rollers, a driving device and a limiting device; the aeration components comprise an aeration air supply tube which is fixed on the truss, aeration air supply branch tubes which are connected with one end of the aeration air supply tube in a radiation manner, fixing brackets which are used for surrounding the aeration air supply branch tubes, and aerators which are arranged inside the fixing brackets and are communicated with the aeration air supply branch tubes; the scraper is arranged at the lower end of the fixing brackets; the air outlet of the fan is communicated with the aeration air supply tube; the blowing unit comprises a blowing air supply tube, blowing air supply branch tubes and air ejectors; one end of the blowing air supply tube is communicated with the air outlet of the fan; the other end of the blowing air supply tube is connected with the blowing air supply branch tubes; the blowing air supply branch tubes are mounted at the lower ends of the fixing brackets; the air ejectors are arranged on the blowing air supply branch tubes and are used for blowing the scraper. By adopting the reciprocation mobile bottom-layer aeration system, dynamic aeration and oxygenation without blind areas or dead zones can be achieved.

Owner:HUATIAN ENG & TECH CORP MCC

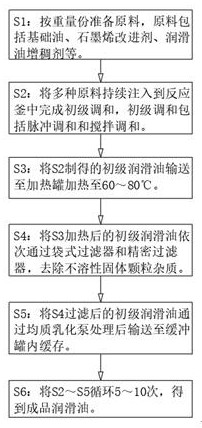

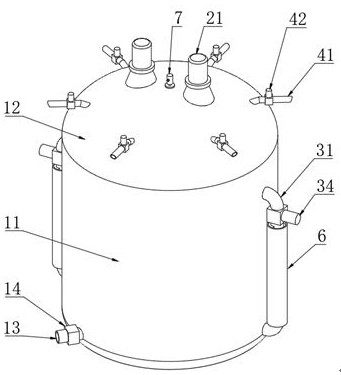

Lubricating oil blending process

ActiveCN113441044AImprove the lubrication effectImprove cold start performanceFlow mixersRotary stirring mixersEngineeringProcess engineering

The invention discloses a lubricating oil blending process which comprises the following steps: firstly, preparing the following raw materials in parts by weight: base oil, a graphene improver, a lubricating oil thickener and the like; performing primary blending on the various raw materials in a reaction kettle to obtain primary lubricating oil, wherein the primary blending comprises pulse blending and stirring blending; conveying the primary lubricating oil to a heating tank to be heated and then filtered through a bag type filter and a precision filter in sequence; treating through a homogeneous emulsification pump, and thoroughly mixing various raw materials to obtain high-grade lubricating oil; and finally replacing various raw materials with high-grade lubricating oil, and circulating the steps for multiple times to obtain the finished product lubricating oil. According to the process, multiple raw materials are firstly subjected to pulse blending and stirring blending and then are thoroughly mixed by the homogenizing and emulsifying pump so that compared with lubricating oil obtained only through stirring blending, the lubricating oil is more uniform and thorough in mixing; meanwhile, the impurity content is greatly reduced through filtration of the bag filter and the precision filter so that the quality of finished lubricating oil is improved.

Owner:兆丰(重庆)科技有限公司

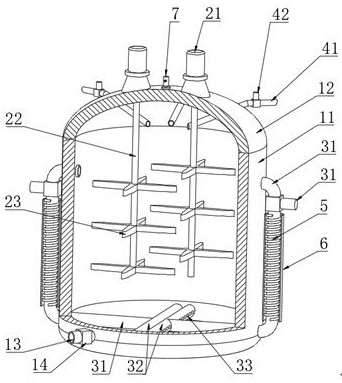

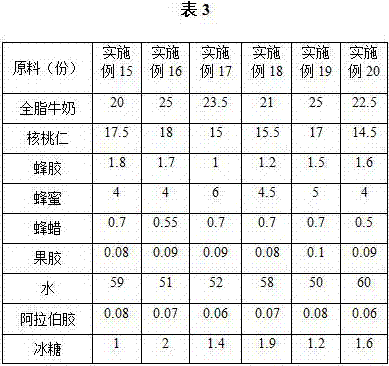

Propolis walnut milk with defecating function

The invention relates to propolis walnut milk with a defecating function. The proplis walnut milk is prepared from the following raw materials in parts by weight: 20 to 25 parts of full-grease milk, 14 to 18 parts of walnut kernels, 1 to 2 parts of propolis, 4 to 6 parts of honey, 0.5 to 0.7 part of beewax, 0.08 to 0.1 part of pectin, 50 to 60 parts of water, 0.06 to 0.08 part of Arabic gum, and 1 to 2 parts of rock candies. The propolis walnut milk provided by the invention is good in taste, stable in tissue state, remarkable in curative effect for constipation, and suitable for constipation crowd to eat for a long time.

Owner:刘国灿

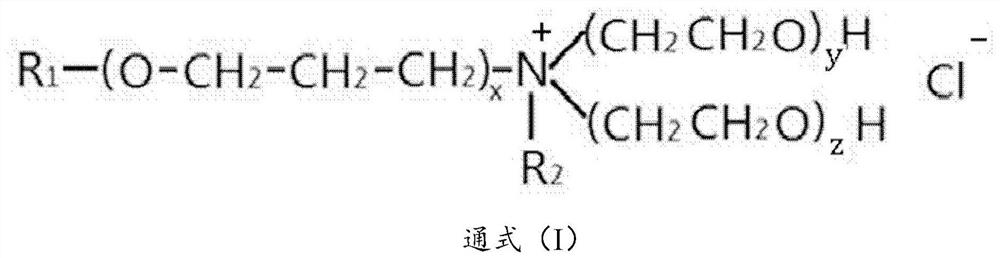

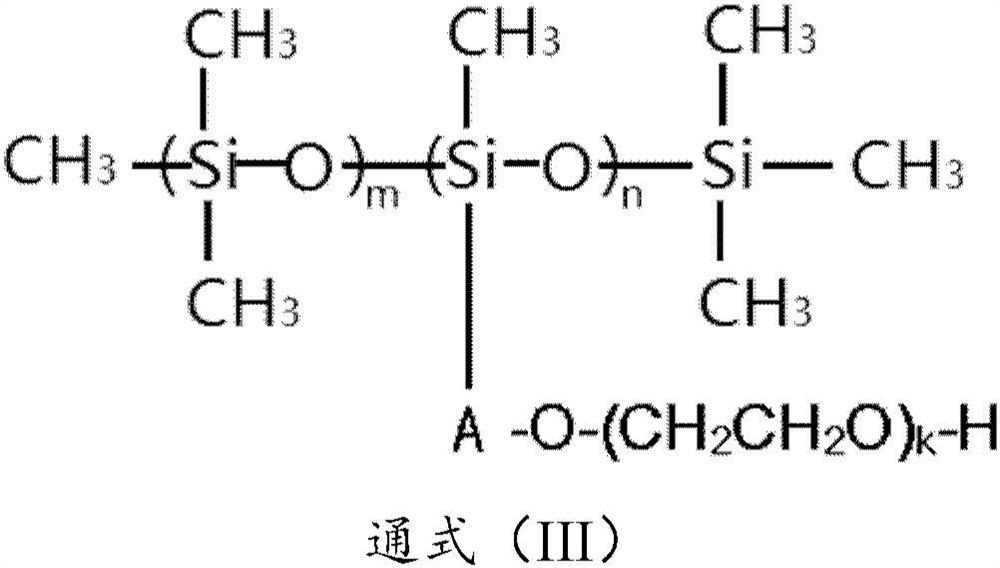

Coating composition with long-term antimicrobial properties

ActiveCN110655815BLong-acting antibacterialReduce odorAntifouling/underwater paintsPaints with biocidesActive agentDioxyethylene Ether

The present invention provides a coating composition with long-term antibacterial properties, the coating composition comprises: 0.1-1% by weight of silicon dioxide nanoparticles; 0.2-10% by weight of quaternary ammonium salt; 20% by weight of fatty alcohol polyoxyethylene ether or fatty alcohol polyoxyethylene ether modified silicone surfactant; and 70‑95% by weight of solvent. The coating compositions according to the invention are capable of forming well-spreading coatings with long-term antimicrobial properties on substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Polishing solution for hard disk magnetic head and preparation method thereof

ActiveCN102174294BImprove suspension stabilityImprove dispersion uniformityOther chemical processesPolishing compositions with abrasivesHydrocarbon solventsMachined surface

The invention discloses polishing solution for a hard disk magnetic head and a preparation method thereof. The polishing solution is mainly prepared from diamond abrasive particles, a dispersing agent, a corrosion inhibitor, a phase transfer solvent, an oil phase medium regulator and a hydrocarbon solvent, wherein the average particle size of the diamond abrasive particles is 30 to 150nm, the particle size distribution of the particles is 20 to 300nm, and the length-diameter ratio of the particles is 1.0 to 2.0. The preparation method comprises the following steps of: mixing diamond powder and a surface modifier, grinding, removing impurities, and grading to obtain suspension slurry; adding the phase transfer solvent into the suspension slurry, and stirring and dispersing the system; removing fine particles and coarse particles in the phase transfer solvent system by grading to ensure that the particle size distribution and concentration of the diamond abrasive particles meet the requirements; and transferring to the hydrocarbon solvent, adding the oil phase medium regulator, the dispersing agent and the corrosion inhibitor, and uniformly stirring to obtain the polishing solution for the hard disk magnetic head. The polishing solution prepared by the method has high suspension stability and dispersion uniformity, and high polishing efficiency during polishing, and a machined surface has high quality.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

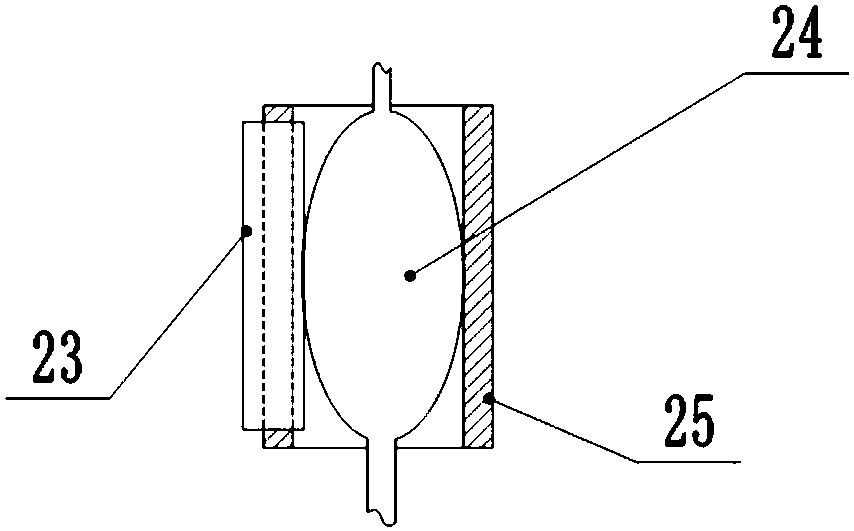

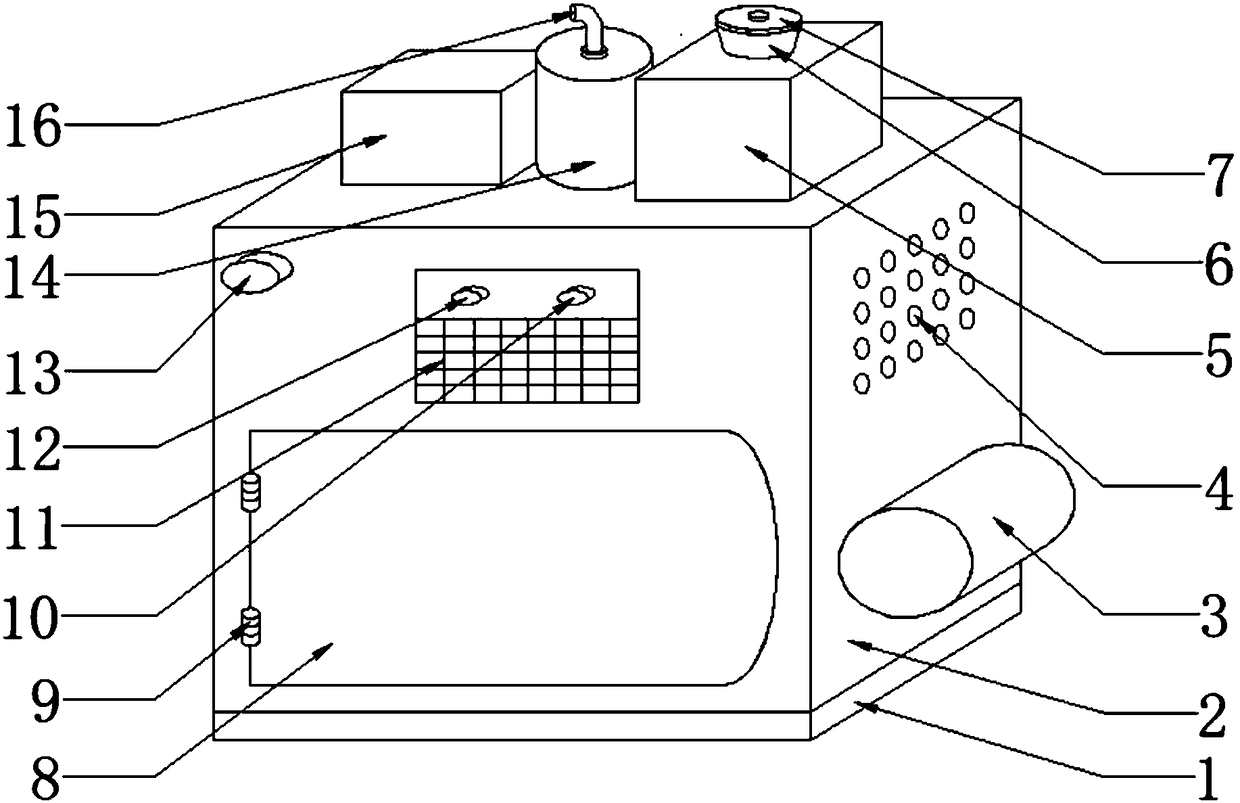

Intelligent steam generator

InactiveCN103557509BNo consumptionNo supplementSteam generation heating methodsEnergy industryEngineeringElectromagnetic heating

The invention discloses an intelligent steam generator. The intelligent steam generator is high in steam generating speed, large in steam generating quantity, capable of achieving steam recycling, easy to operate, fully-intelligent in operation, energy-saving and environmentally friendly and comprises an intelligent control system, a water supplying and atomizing device and a hot steam generating device, wherein the water supplying and atomizing device and the hot steam generating device are connected with the intelligent control system. The hot steam generating device comprises an atomizer (24), an atomizing diverter pipe (25), an steam generating pipe (22), a steam storage container (30) and a steam diverter (29), wherein the atomizer (24) is connected to the atomizing diverter pipe (25), the atomizing diverter pipe (25) is connected to the steam generating pipe (22), and the steam generating pipe (22) is connected to the steam storage container (30). The intelligent steam generator can achieve waste steam bottom filling recycling and avoid superfluous consumption; is energy-saving and environmentally friendly due to an electromagnetic heating mode; avoids potential risks due to high consumption over small supplementation; achieve fully automatic control and convenient operation through single-step setting; achieves cleanliness during the whole process due to the fact that no sediment exists in the device.

Owner:邵道德

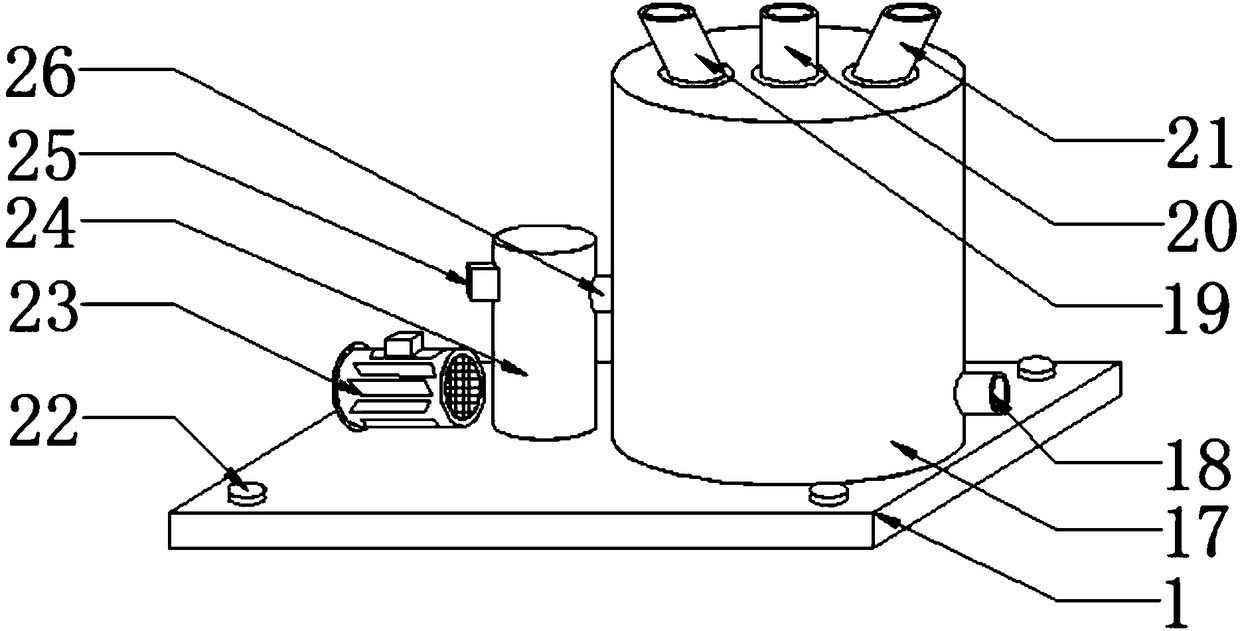

Lithium carbonate carbonic acid hydrogenation device

InactiveCN108295791ANo sedimentationReduce workloadChemical/physical/physico-chemical stationary reactorsLithium carbonates/bicarbonatesLithiumLithium carbonate

The invention discloses a lithium carbonate carbonic acid hydrogenation device. The lithium carbonate carbonic acid hydrogenation device comprises a device box, a lithium hydrogencarbonate collectingtank and cooling holes are formed in one side of the device box, a lithium carbonate storage tank, a water tank and a precipitator storage box are arranged at the top of the device box, a device box baseboard is arranged at the bottom of the device box, fixed bolts, a driving motor and a carbon dioxide storage tank are arranged at the top of the device box baseboard, a concentration sensor is arranged at one side of the carbon dioxide storage tank, a connecting pipe is arranged at the other side of the carbon dioxide storage tank, a reaction tank is arranged at one end of the connecting pipe,a discharging opening is formed in one side of the reaction tank, a precipitator inlet, a water inlet and a lithium carbonate inlet are formed in the top of the reaction tank, a reaction tank cavity is formed inside the reaction tank, a stirring shaft is arranged at the bottom of the reaction tank cavity, a stirring plate and stirring blades are arranged on the outer surface of the stirring shaft.Therefore, by means of the lithium carbonate carbonic acid hydrogenation device, the problem of deposition of lithium carbonate is solved through the stirring shaft and the stirring blades.

Owner:宜春市鼎鑫高能科技有限公司

A kind of instant berberine preparation and preparation method and application thereof

ActiveCN104430400BImprove hydrophilic abilityEffective combinationBiocideDisinfectantsBerberineSolubility

The invention discloses an instant berberine preparation, a preparation method and application of the instant berberine preparation. By utilizing strong electrostatic interaction between synthesized polyacrylic resin and berberine molecules, the solubility of the berberine is greatly improved; the synthesized instant berberine can be mixed and dissolved in water according to any proportion, so that the solubility of the berberine is increased by more than 200 times. The synthesis process of the instant berberine preparation is performed by two steps of synthesizing high-hydrophilia negative-charge-rich polyacrylic resin with a coating function, which is called as a negative-electricity hydrophilic resin; fully mixing the berberine and the negative-electricity hydrophilic resin to obtain a yellow cream, namely the instant berberine cream. The negative-electricity resin is suitable for preparing the instant berberine, and also other low-solubility organic pharmaceutical molecules. The synthesized instant berberine cream can be further dried and smashed to obtain instant berberine powder. The instant berberine cream and the instant berberine powder can be mixed and dissolved in water according to any proportion. The instant berberine can be used for preparing a sterilization agent and a harmful blue-green algae inhibiting agent.

Owner:TIANJIN AGRICULTURE COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com