Preparation method of decontamination type laundry detergent

A technology for laundry detergent and solution, applied in mixing methods, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of poor stain removal effect of laundry liquid, reduced surface activity of laundry liquid, insufficient emulsification of raw materials, etc. To achieve the effect of improving surface activity, promoting mixing, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

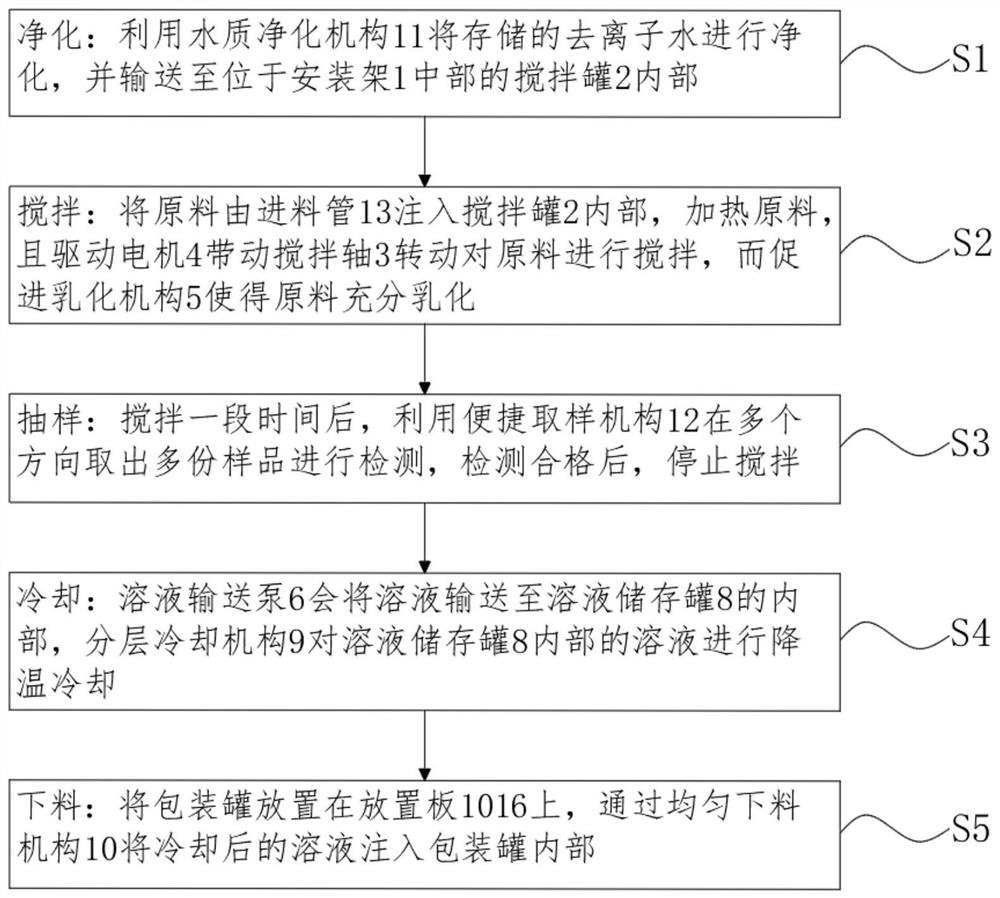

[0045] Example: such as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of decontamination type laundry liquid preparation method, comprises the steps:

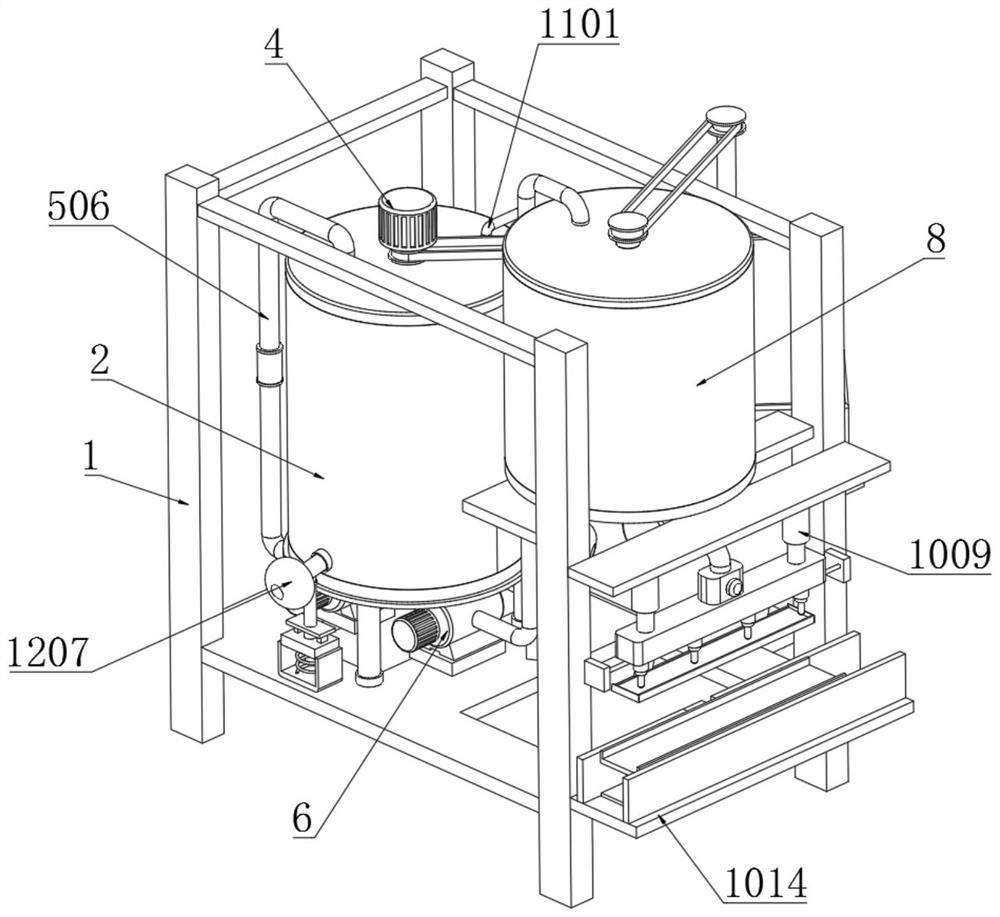

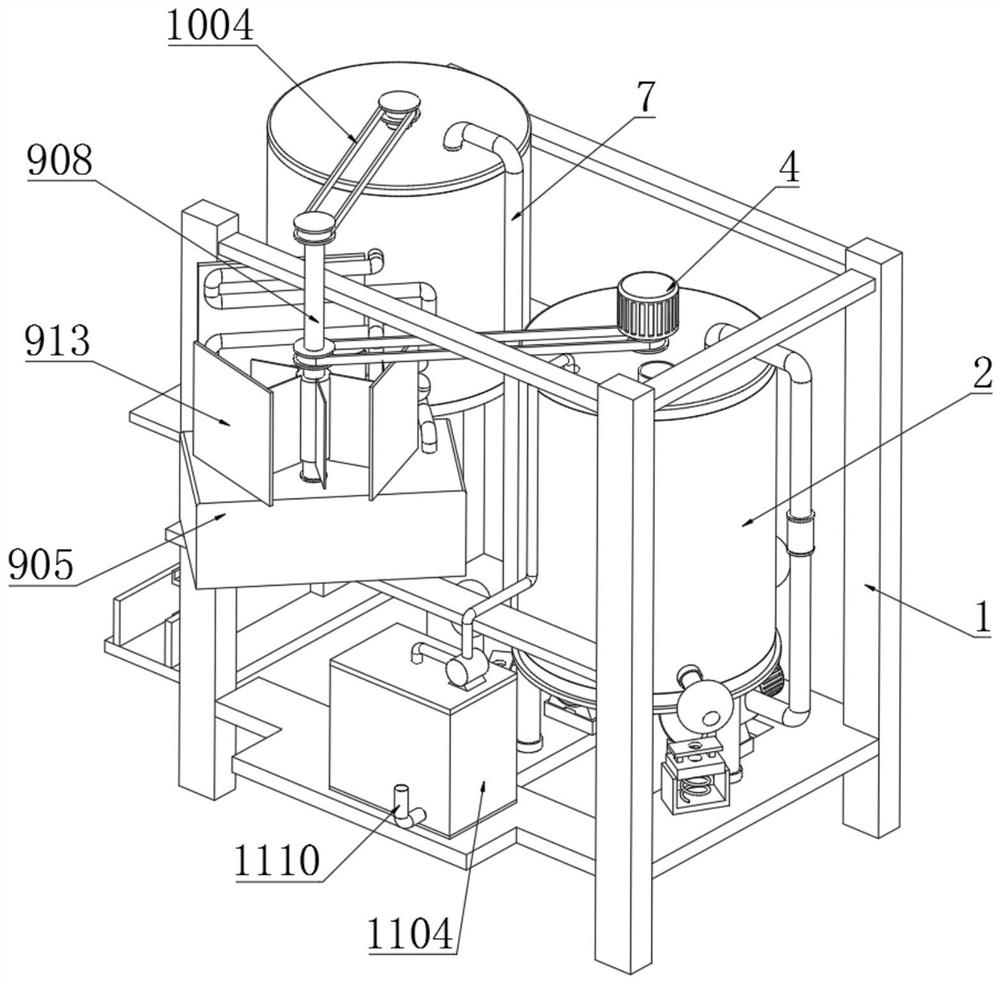

[0046] S1; purification: use the water quality purification mechanism 11 to purify the stored deionized water, and transport it to the inside of the mixing tank 2 located in the middle of the installation frame 1;

[0047] S2: Stirring: the raw material is injected into the stirring tank 2 through the feed pipe 13, the raw material is heated, and the driving motor 4 drives the stirring shaft 3 to rotate to stir the raw material, and the emulsification mechanism 5 is promoted to fully emulsify the raw material;

[0048] S3: Sampling: After stirring for a period of time, use the convenient sampling mechanism 12 to take out multiple samples in multiple directions for testing, and stop stirring after passing the test;

[0049] S4: cooling: the solution delivery pump 6 will deliver the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com