Lithium ion battery anode slurry and preparation method thereof

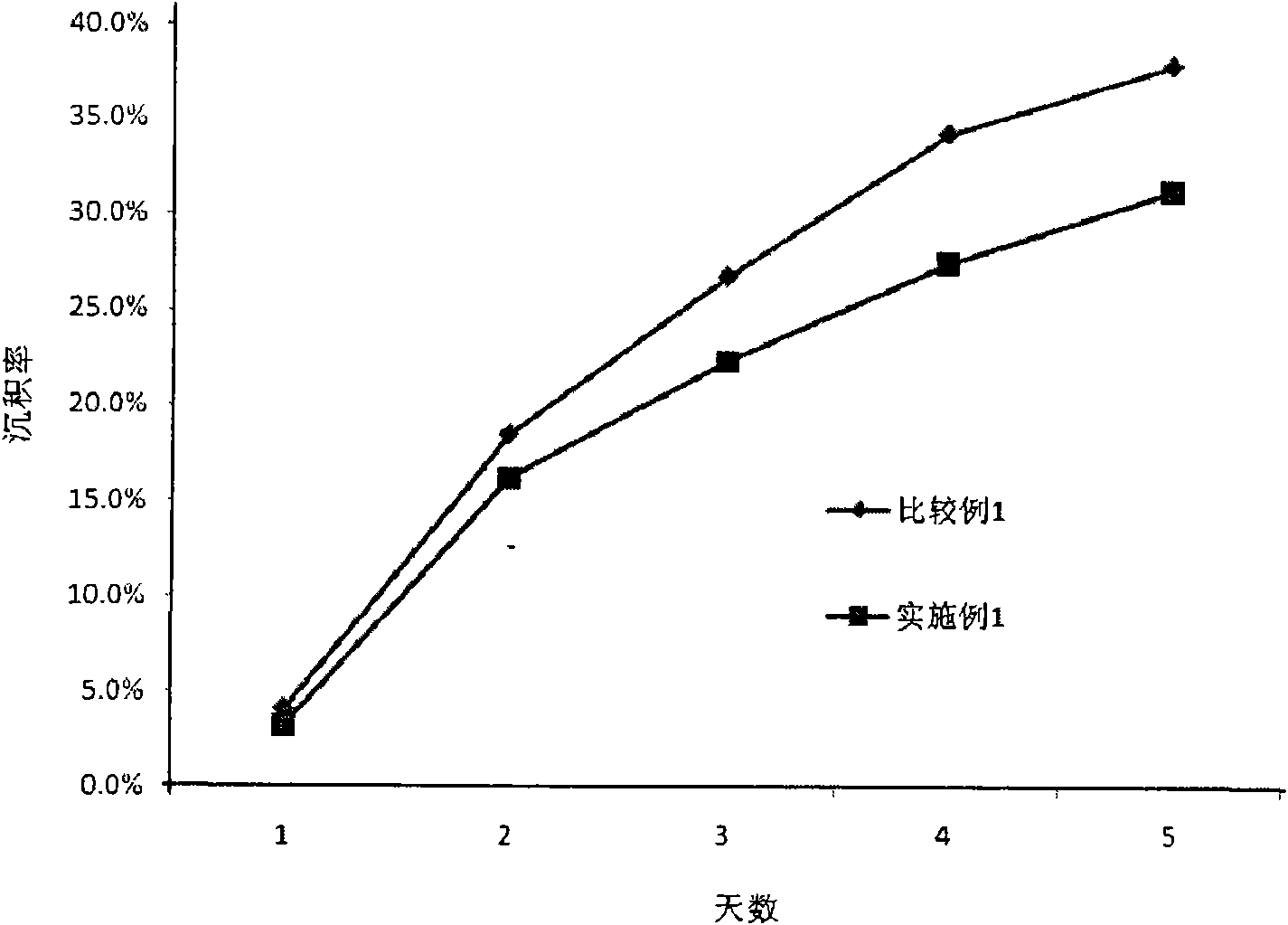

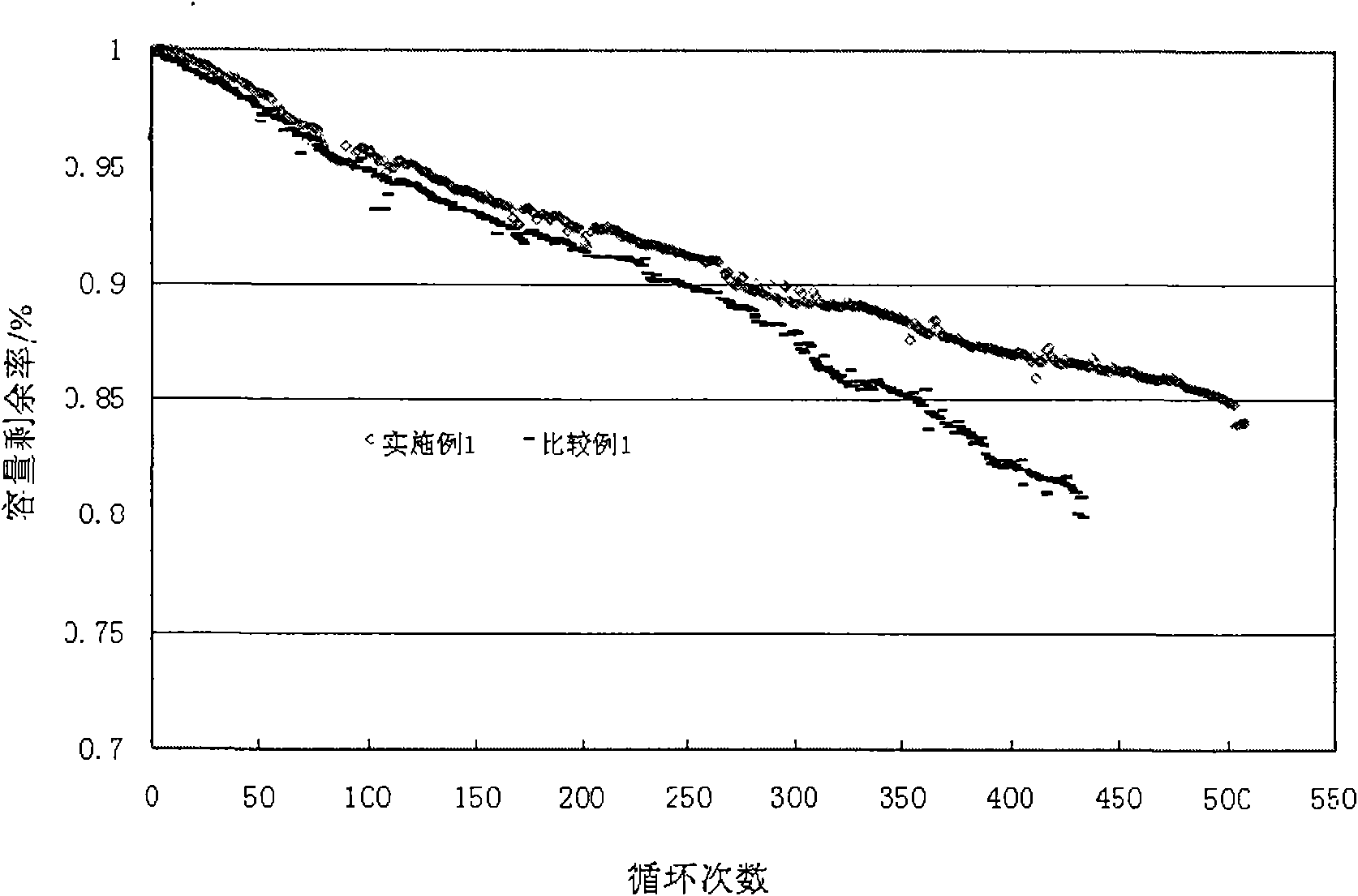

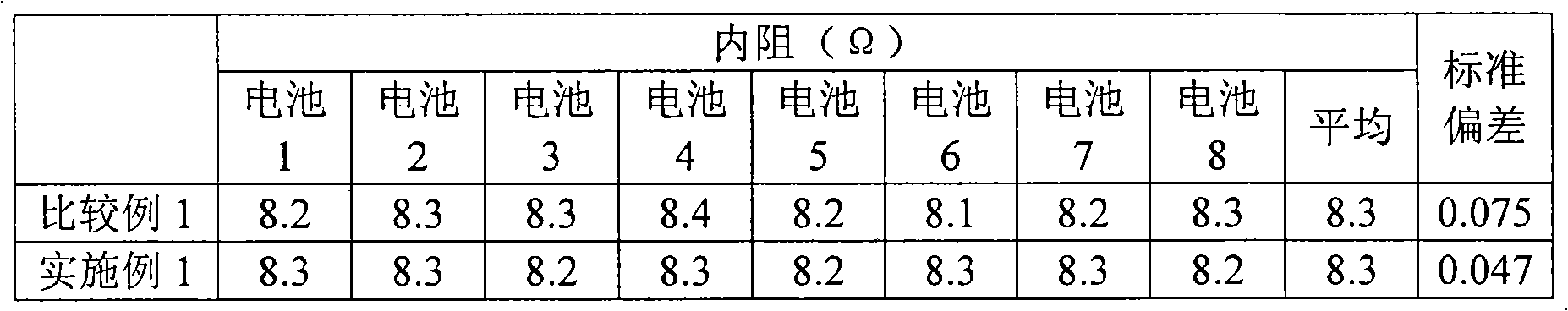

A lithium-ion battery and positive electrode slurry technology, which is applied in the direction of electrode manufacturing, secondary batteries, active material electrodes, etc., can solve the problems of uneven thickness distribution of the electrode sheet, insufficient stability, slurry deposition, etc., and achieve consistent improvement stability and cycle performance, improved stability, and improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This example illustrates the preparation method of the lithium manganate positive electrode slurry provided by the present invention.

[0021] 1. Drying of positive active material

[0022] The positive electrode active material lithium manganese oxide was baked at 110°C for 12 hours in a vacuum environment of 0.05 MPa, and cooled to room temperature with dry gas with a dew point temperature of -50°C.

[0023] 2. Preparation of positive electrode

[0024] Taking 50g / part as an example, dissolve 225g polyvinylidene fluoride (PVDF, F2) in 3250g N-methylpyrrolidone (NMP) solvent and mix for 6-8 hours to make gel, and then dry 4350g lithium manganate , 175g of carbon black, 250g of dispersant hypermer kd-1 (British Croda Company) were added to the above solution, and fully stirred for 8-12 hours to obtain positive electrode slurry. Apply the slurry to a 20 μm aluminum foil with a coater, heat and dry in vacuum at 120°C for 2 hours, roll and cut into pieces to obtain 500mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com