Preparation method of laser induced mono-disperse Ag-Ag2S nano-particle photocatalyst

A nanoparticle, laser-induced technology, applied in physical/chemical process catalysts, chemical instruments and methods, light water/sewage treatment, etc., to achieve the effect of simple method and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

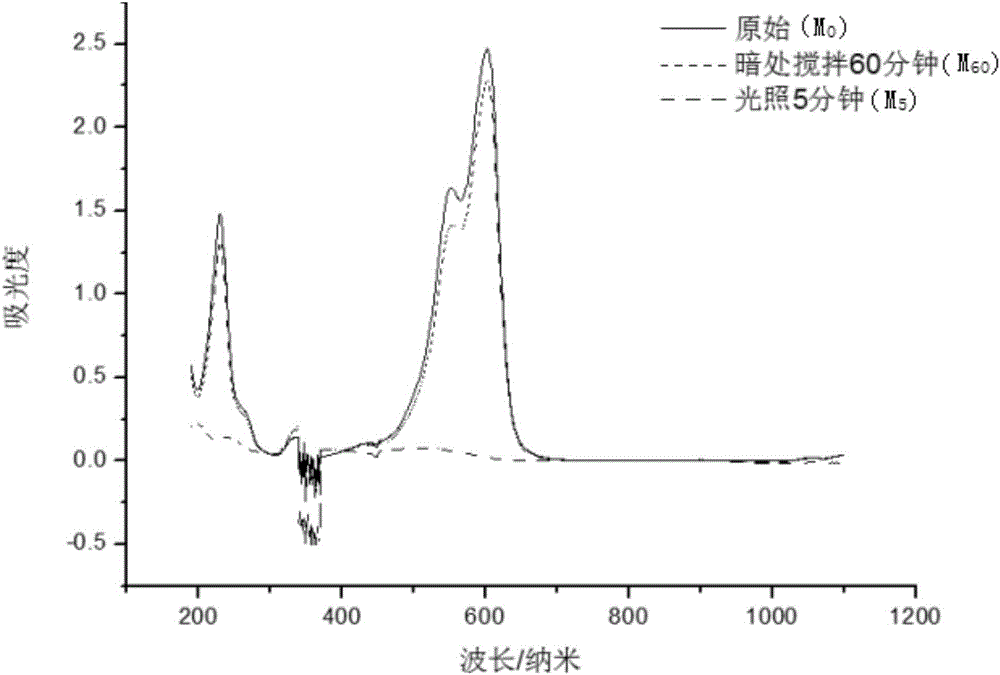

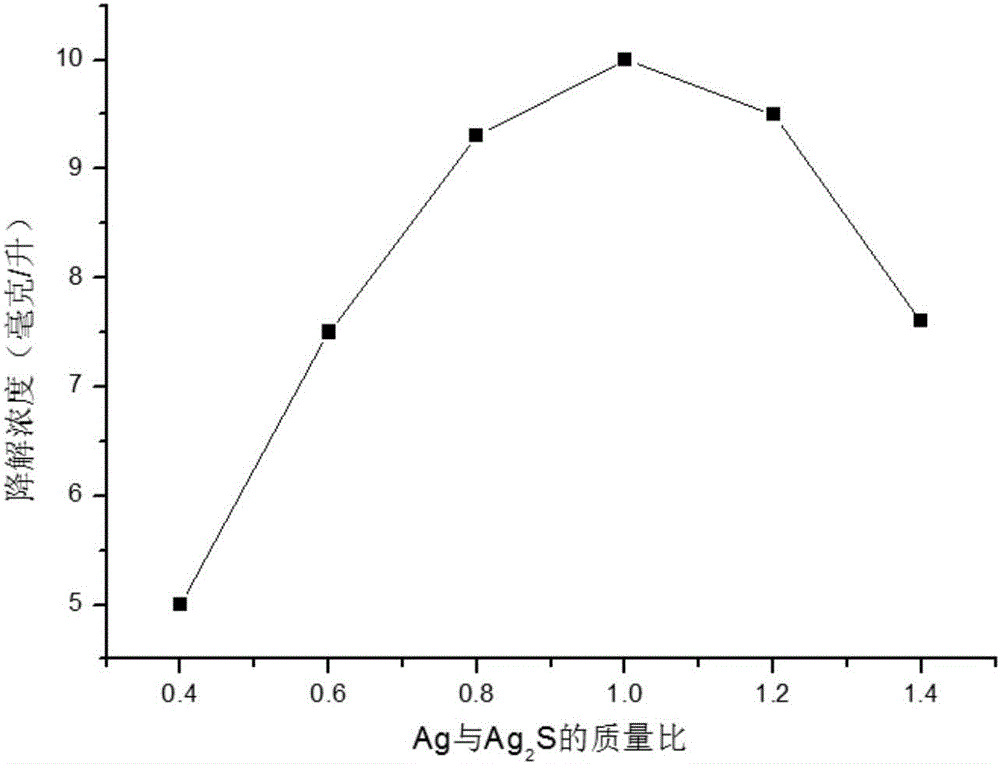

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A laser-induced monodisperse Ag-Ag 2 The preparation method of S nanoparticle photocatalyst comprises the steps:

[0024] (1) Add reaction liquid in rotating container, described reaction liquid is the aqueous solution containing TAA and CTAB, and the concentration of described TAA is 0.2M, and the concentration of CTAB is 0.05M;

[0025] (2) The Ag sheet is immersed in the reaction solution after polishing, and rotated for 30 minutes at 350 rpm;

[0026] (3) Under the conditions of emitting laser wavelength 1064nm, pulse duration 10ns, and frequency of 10Hz, the laser beam is focused on the Ag sheet in the rotating container by a quartz lens with a focal length of 65mm for 30min, so that the average diameter of the laser beam on the surface of the Ag sheet is 370μm, the laser power density is 6~9GW / cm 2 ;

[0027] (4) Take out the Ag sheet after laser irradiation from the rotating container, rinse the product collected on the surface of the Ag sheet after laser irra...

Embodiment 2

[0029] A laser-induced monodisperse Ag-Ag 2 The preparation method of S nanoparticle photocatalyst comprises the steps:

[0030] (1) Add reaction liquid in rotating container, described reaction liquid is the aqueous solution containing TAA and CTAB, and the concentration of described TAA is 0.2M, and the concentration of CTAB is 0.05M;

[0031] (2) The Ag sheet is immersed in the reaction solution after polishing, and rotated for 40 minutes at 300 rpm;

[0032] (3) Under the conditions of emitting laser wavelength 1064nm, pulse duration 10ns, and frequency of 10Hz, the laser beam is focused on the Ag sheet in the rotating container by a quartz lens with a focal length of 65mm for 30min, so that the average diameter of the laser beam on the surface of the Ag sheet is 370μm, the laser power density is 6~9GW / cm 2 ;

[0033] (4) Take out the Ag sheet after laser irradiation from the rotating container, rinse the product collected on the surface of the Ag sheet after laser irra...

Embodiment 3

[0035] A laser-induced monodisperse Ag-Ag 2 The preparation method of S nanoparticle photocatalyst comprises the steps:

[0036] (1) Add reaction liquid in rotating container, described reaction liquid is the aqueous solution containing TAA and CTAB, and the concentration of described TAA is 0.2M, and the concentration of CTAB is 0.05M;

[0037] (2) The Ag sheet is immersed in the reaction solution after polishing, and rotated for 20 minutes at 400 rpm;

[0038] (3) Under the conditions of emitting laser wavelength 1064nm, pulse duration 10ns, and frequency of 10Hz, the laser beam is focused on the Ag sheet in the rotating container by a quartz lens with a focal length of 65mm for 30min, so that the average diameter of the laser beam on the surface of the Ag sheet is 370μm, the laser power density is 6~9GW / cm 2 ;

[0039] (4) Take out the Ag sheet after laser irradiation from the rotating container, rinse the product collected on the surface of the Ag sheet after laser irra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com