Integration method of high-reliability power hybrid integrated circuit

A hybrid integrated circuit and integrated method technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of heat dissipation speed on the back of the substrate, sintering bubbles and pinholes in the thick film silver metal layer, and improve adhesion and heat. The effect of transferring, enhancing adhesion and heat dissipation, and ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

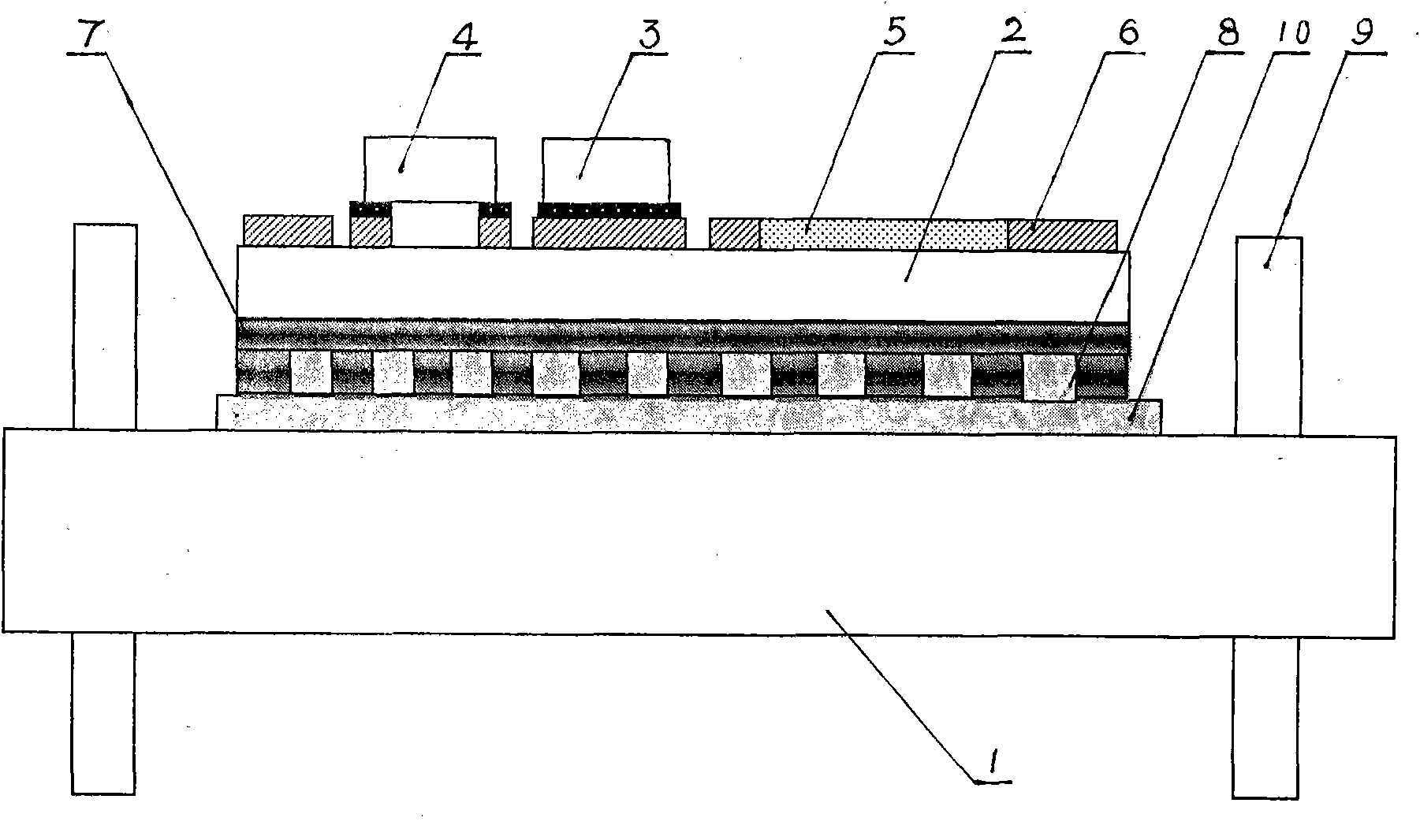

[0024] Guizhou Zhenhua Fengguang Semiconductor Co., Ltd. developed a highly reliable power hybrid integrated circuit for the FX0041 power operational amplifier. The integration method is:

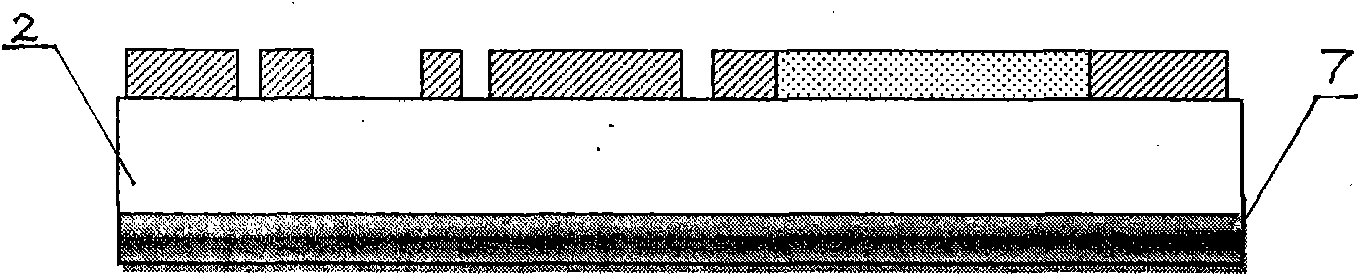

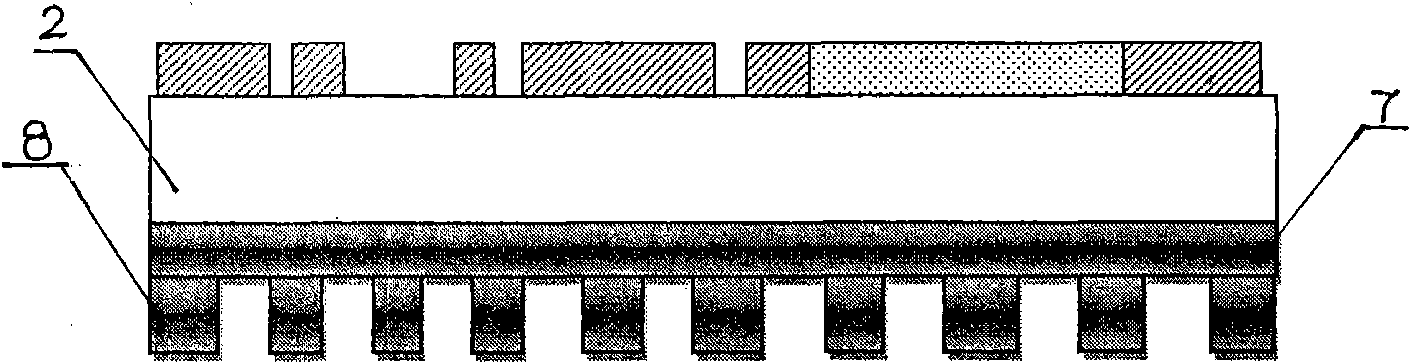

[0025] (1) First prepare the substrate: substrate cleaning and drying, including printing and drying of thick film conductor paste (150°C, 10min), sintering conductor (875°C, 12min, total time 45min), printing and drying Resistor paste (150°C, 10min), sintering resistor (850°C, 10min, total time 35min); adjusting resistor (laser trimming), glass glaze printing and drying (150°C, 10min), sintering glass glaze (500 ℃, 10min, the total time is 30min), forming the conductor pattern of the pad (bonding area); the substrate is then cleaned and dried (100℃, 30min);

[0026] (2) Position, align and fix in the special stainless steel fixture, and place it in the magnetron sputtering table for installation and fixation; place cleaned and dried Cu, Ni-Cr, Au in the position of the sputtering source, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com