Multicolor pre-coating film

A pre-coating and color mixing technology used in the printing field to achieve cost savings and fewer pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

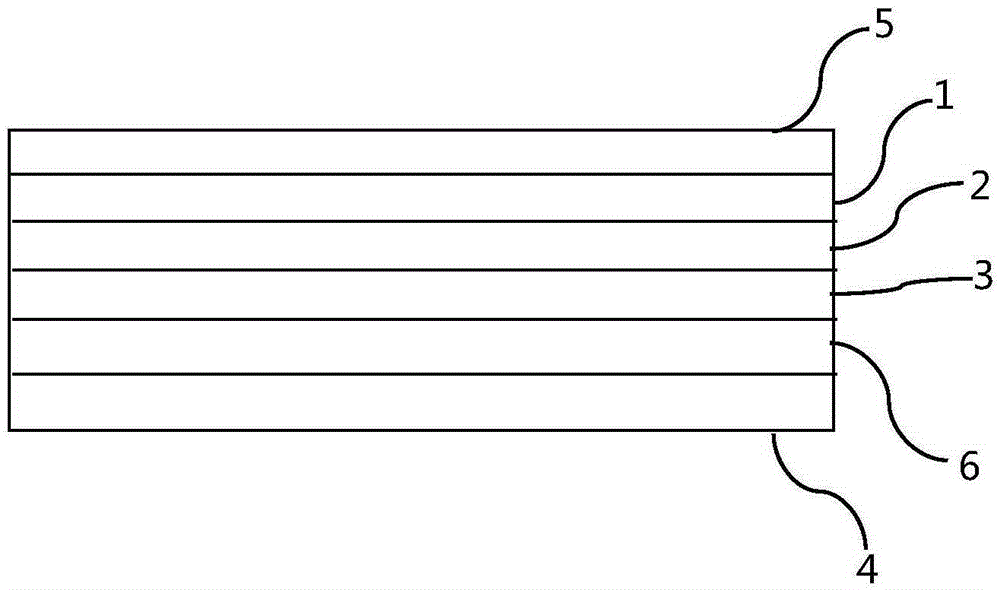

[0048] Step 1. Gravure printing on the inner layer of a polyester (PET) film with a width of 1250mm and a thickness of 30μm to produce a pattern layer with a predetermined effect after a polyurethane two-component ink and a transparent laser particle mixed resin. The average thickness of the ink layer is 1.6μm;

[0049] Step 2. Coating a polymethyl methacrylate (PMMA) weather-resistant resin layer with a width of 1240 mm and a thickness of 16 ± 1 μm on the outer surface of the polyester (PET) film;

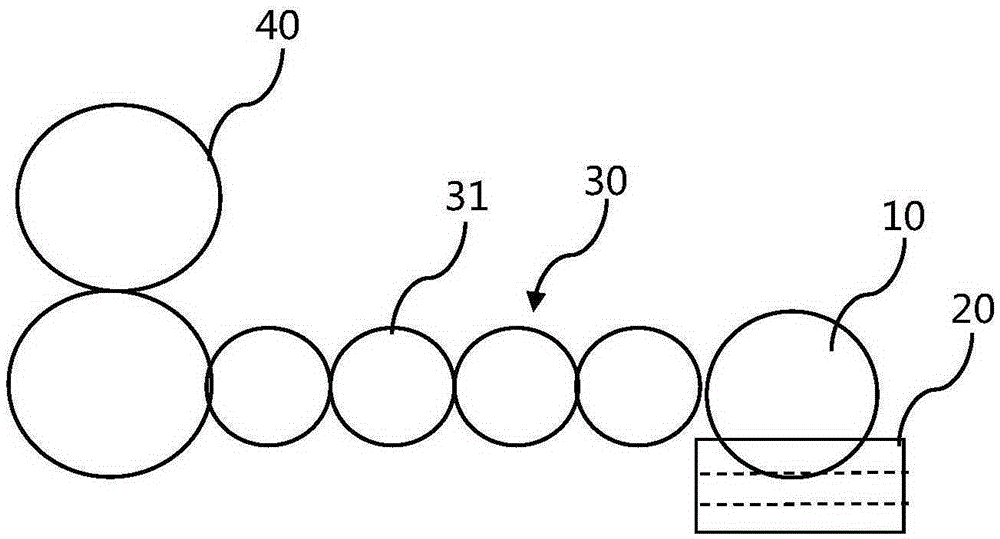

[0050] Step 3. The pre-coated film is made by coating the water-based base coat by the extrusion laminating machine and extruding the composite hot melt adhesive resin. The primer layer is made of polyethyleneimine or ethylene-acrylic acid copolymer or polymer polyester aqueous solution, and the solid content is 0.7% to 5.5%; the dry weight of the primer layer is 0.07g / m 2 , The thickness is 0.04μm.

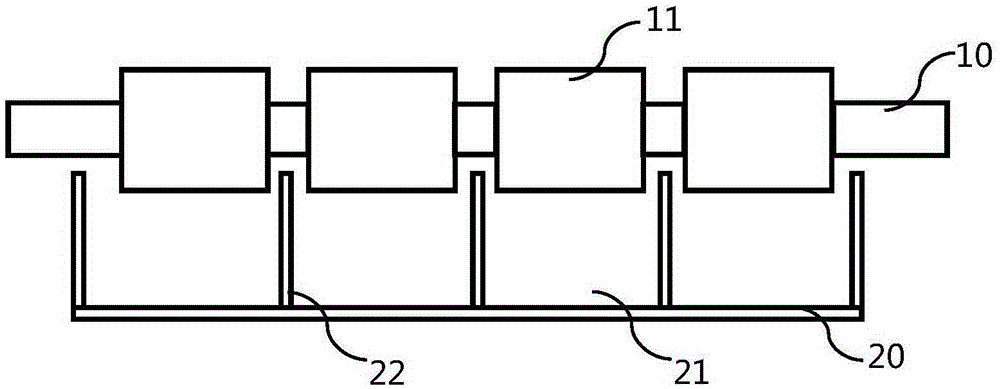

[0051] Pre-coating hot-melt adhesive resin process: Cast the hot-melt adhesive resin tw...

Embodiment 2

[0062] Step 1. On the inner layer of a polyester (PET) film with a width of 1250mm and a thickness of 30μm, gravure printed polyurethane two-component ink and transparent laser particles mixed with resin to produce a pattern layer with a predetermined effect;

[0063] Step 2. On the outer surface of the polyester (PET) film, coat a functional layer of a UV curable resin layer with a width of 1240mm and a thickness of 15±1μm, and then harden to form an anti-scratch layer after passing through a UV curing machine, and then rewind;

[0064] Step 3. On the solvent-free laminating machine, it is compounded with the 80μm thick PE heat-sealable film. The solvent-free two-component polyurethane adhesive resin is used. The cooling roller and the squeeze roller are used to combine with the PET film to form a glue. Floor. The aging period is 24h, and the peel force value is greater than 10N / 15mm. After slitting and trimming, a pre-coated film is made, and the total thickness of the pre-coate...

Embodiment 3

[0072] Using the coating machine dip coating process, the thickness of the single roll three dip coating is 12μm. The heat-sensitive adhesive is prepared from butanol-modified melamine resin, paraffin wax, rosin, 582 resin and solvent. The solvent is a mixture of methyl ethyl ketone and ethyl acetate.

[0073] Step 1. On the inner layer of a polyester (PET) film with a width of 1250mm and a thickness of 30μm, gravure printed polyurethane two-component ink and transparent laser particles mixed with resin to produce a pattern layer with a predetermined effect;

[0074] Step 2. On the outer surface of the polyester (PET) film, coat the brightening resin coating with a width of 1242mm and a thickness of 10±1μm, heat and dry it in the drying tunnel of the coating machine, and solidify to form a brightening functional layer, and then rewind;

[0075] Step 3. Dip-coating the heat-sensitive adhesive resin by a coater or dry laminating machine to form a pre-coated film. It is coated three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com