Inversion perovskite solar cell containing alkali metal halide hole modification layer and preparation method thereof

A technology of alkali metal halides and solar cells, applied in the field of solar cells, can solve the problems of difficult large-scale preparation and commercialization, incomplete coverage of perovskites, and limited battery performance, achieving low cost, improved performance, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

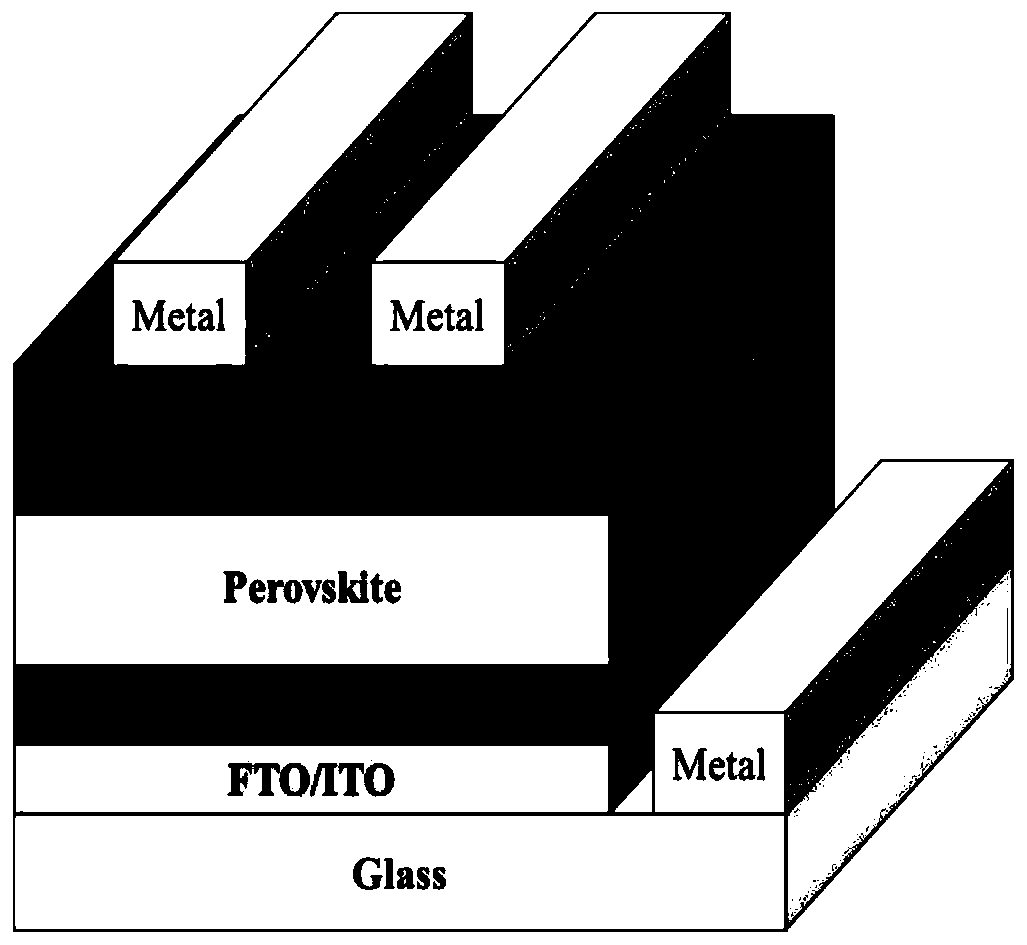

[0038] An inverse perovskite solar cell, comprising a conductive substrate, and a stacked structure arranged on part of the conductive substrate, the stacked structure includes a hole transport layer, a hole layer, and a hole transport layer stacked sequentially from bottom to top The transport layer modification layer, the perovskite light absorbing layer, the electron transport layer and the metal electrode, and a part of the metal electrode is also provided on the conductive substrate, and this part of the metal electrode is not in contact with the stacked structure.

[0039] The above conductive substrate is FTO conductive glass, the material used for the hole transport layer is nickel oxide, and the thickness of the nickel oxide is 20nm; the material used for the hole transport layer modification layer is alkali metal halide CsI, and the thickness is 25nm; the perovskite light absorbing layer The material used is CH 3 NH 3 PB 3 The perovskite light-absorbing layer has a...

Embodiment 2

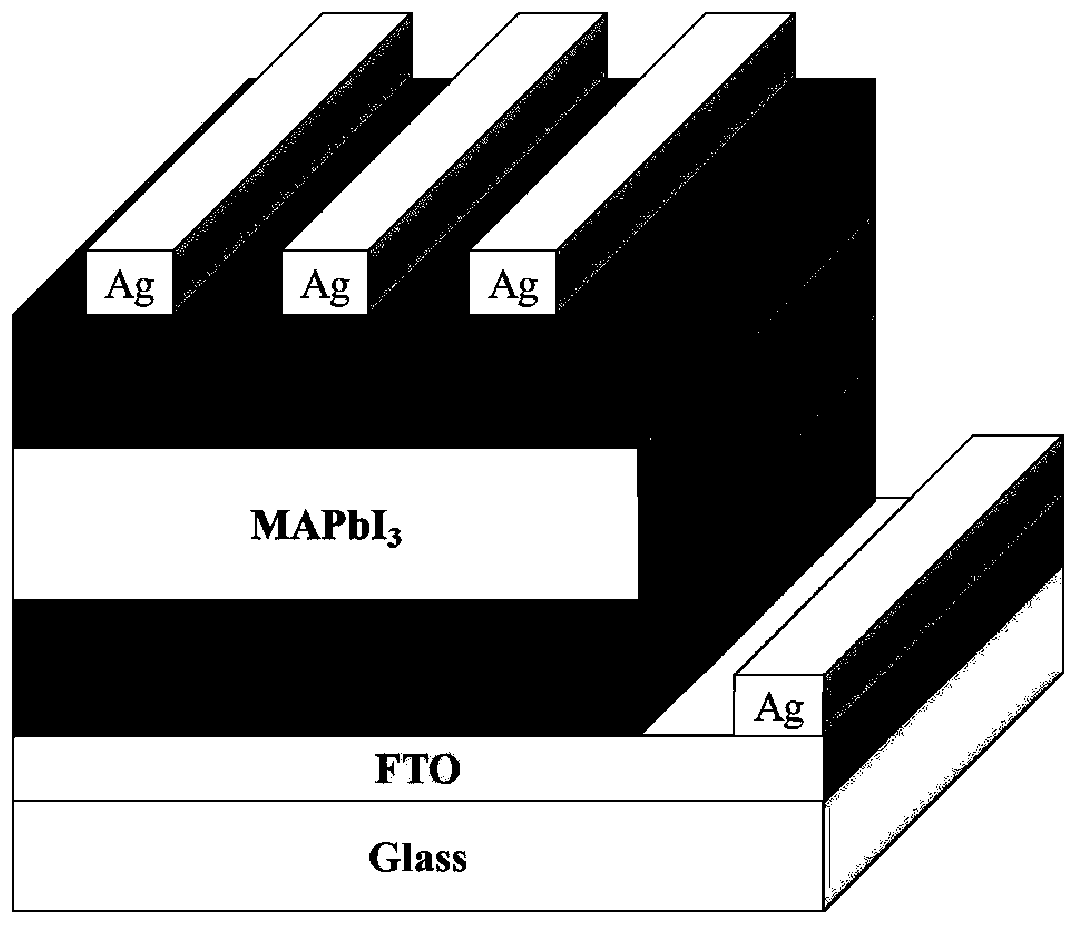

[0052] An inverse perovskite solar cell with a device structure such as figure 2 As shown, it includes a conductive substrate, and a laminated structure provided on part of the conductive substrate, the laminated structure includes a hole transport layer, a hole transport layer modification layer, a perovskite stacked sequentially from bottom to top ore light-absorbing layer, electron transport layer, electron transport layer modification layer and metal electrode, and a part of metal electrode is also provided on the conductive substrate, and this part of metal electrode is not in contact with the laminated structure.

[0053] The above conductive substrate is FTO conductive glass, the material used for the hole transport layer is nickel oxide, and the thickness of the nickel oxide is 20nm; the material used for the hole transport layer modification layer is alkali metal halide CsI, and the thickness is 25nm; the perovskite light absorbing layer The material used is CH 3 NH...

Embodiment 3

[0056] An inverse perovskite solar cell with a device structure such as figure 2 As shown, it includes a conductive substrate, a hole transport layer, a hole transport layer modification layer, a perovskite light-absorbing layer, an electron transport layer and a metal electrode that are stacked sequentially from bottom to top.

[0057] The above-mentioned conductive substrate is FTO conductive glass, the material used for the hole transport layer is nickel oxide, and the thickness of the nickel oxide is 20nm; the material used for the modification layer of the hole transport layer is alkali metal halide CsCl, and the thickness is 25nm; The material used is CH 3 NH 3 PB 3 The perovskite light-absorbing layer has a thickness of 300nm; the material used for the electron transport layer is PCBM, and the thickness is 20nm; the metal electrode is a silver electrode, and the thickness is 100nm.

[0058] The preparation process of the above-mentioned device is the same as in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com