Metallic surface glittering effect simulated pre-coated film for packaging and manufacturing method of metallic surface glittering effect simulated pre-coated film

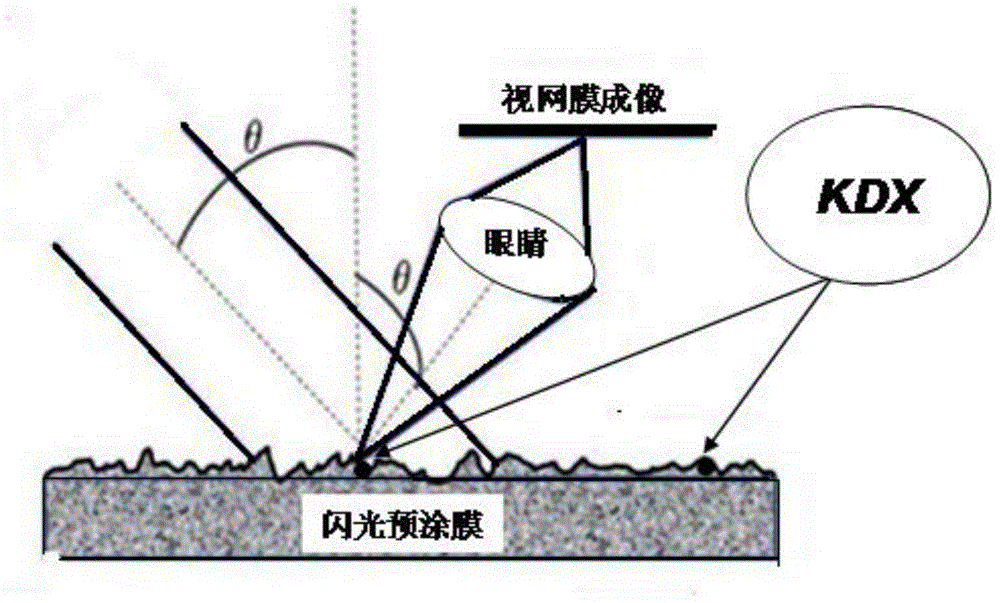

A production method and technology of pre-coating film, applied in the directions of packaging, wrapping paper, transportation and packaging, etc., can solve the problems of not forming the product market scale, insufficient technical integration ability, difficult to realize packaging application, etc., and achieve the ability to block the penetration of corrosive media. High, low pollution, less pinhole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

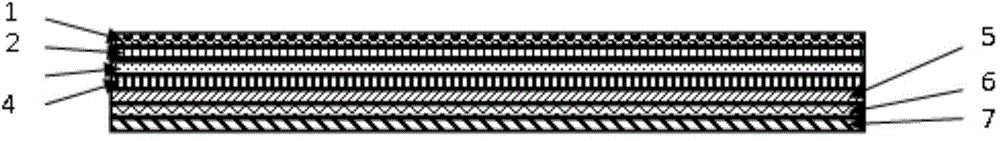

[0048] Printing ink layer / aluminum layer / reinforced aluminized resin layer / molded resin layer / CPP / primer layer / hot melt adhesive layer structure imitation metal surface effect packaging pre-coating film, specifically includes the following steps:

[0049] Step 1, coating the molded resin layer 4 on the film layer 5;

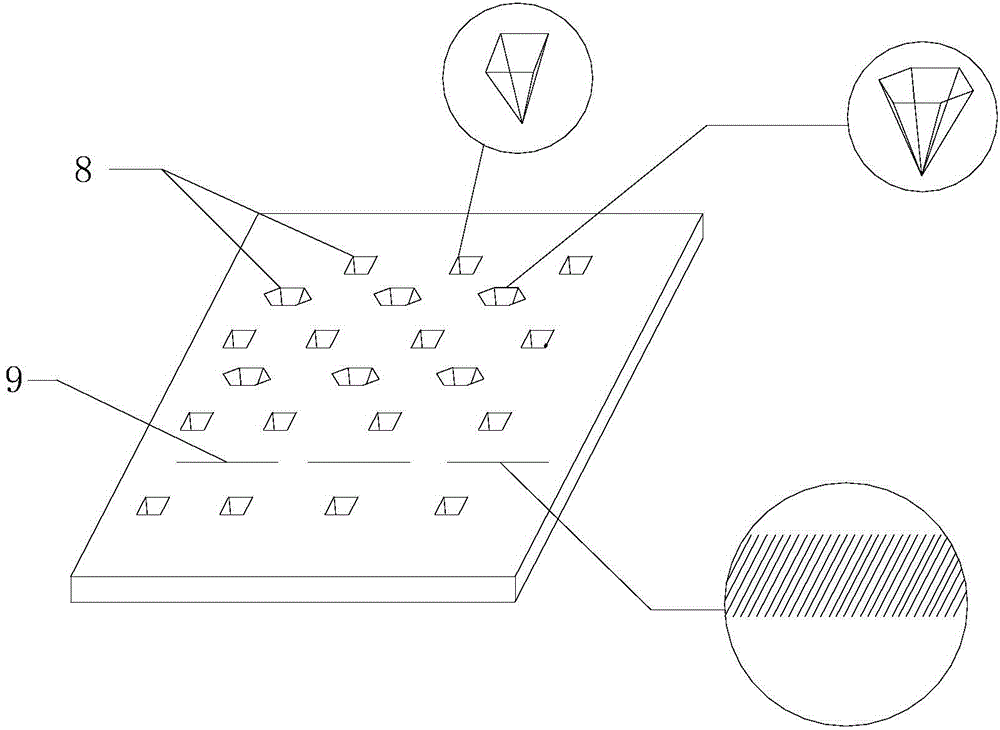

[0050] Step 2. Use hot molding process to mold quadrangular pyramid and hexagonal pyramid notches 8 on the molded resin layer 4 under the condition of 95-110°C. The depth of quadrangular pyramid and hexagonal pyramid notches 8 is 10-20 μm; at the same time, use the same machine to divide The image of the enciphered anti-counterfeit grating notch 9 is molded on the molded resin layer 4 by roller operation, wherein the image depth of the grating notch 9 is ≤1 μm;

[0051] Step 3, coating the reinforced aluminized layer 3 on the molded resin layer 4 obtained in step 2, and the vacuum-evaporated aluminum layer 2;

[0052] Step 4: using a gravure printing machine to ...

Embodiment 2

[0063] Ink layer / aluminum layer / reinforced aluminized resin layer / molded resin layer / PVC / primer layer / hot melt adhesive layer structure imitation metal surface effect packaging pre-coated film:

[0064] The thickness of the PVC film is 150 μm, and the width is 1250 mm. The process is consistent with that of Example 1, that is, the printing color layer 1+aluminized layer 2+reinforced aluminized resin layer 3+molded resin layer 4+PVC film 5+undercoat layer 6+ EEA hot melt adhesive layer7. Just after finishing the 1-5 process of embodiment 1, carry out UV ink layer gravure printing.

[0065] The thermoplastic polymer material layer of the metal-like surface effect pre-coating film of the present invention can be directly bonded and covered with paper, furniture boards, plastic boards, aluminum-plastic plates and steel plates in a state of hot pressing and melting. The invention has no other additives in the production and processing process, and the pollution is lower than that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com