Alterant for ADC12 aluminum alloy and alteration method of alloy

A technology of ADC12 and aluminum alloy, which is applied in the field of modifiers for aluminum alloys, can solve the problems of poor mechanical properties, easy decay, unstable refinement effect of modifiers, etc., and achieve excellent performance, not easy to decay, and stable refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

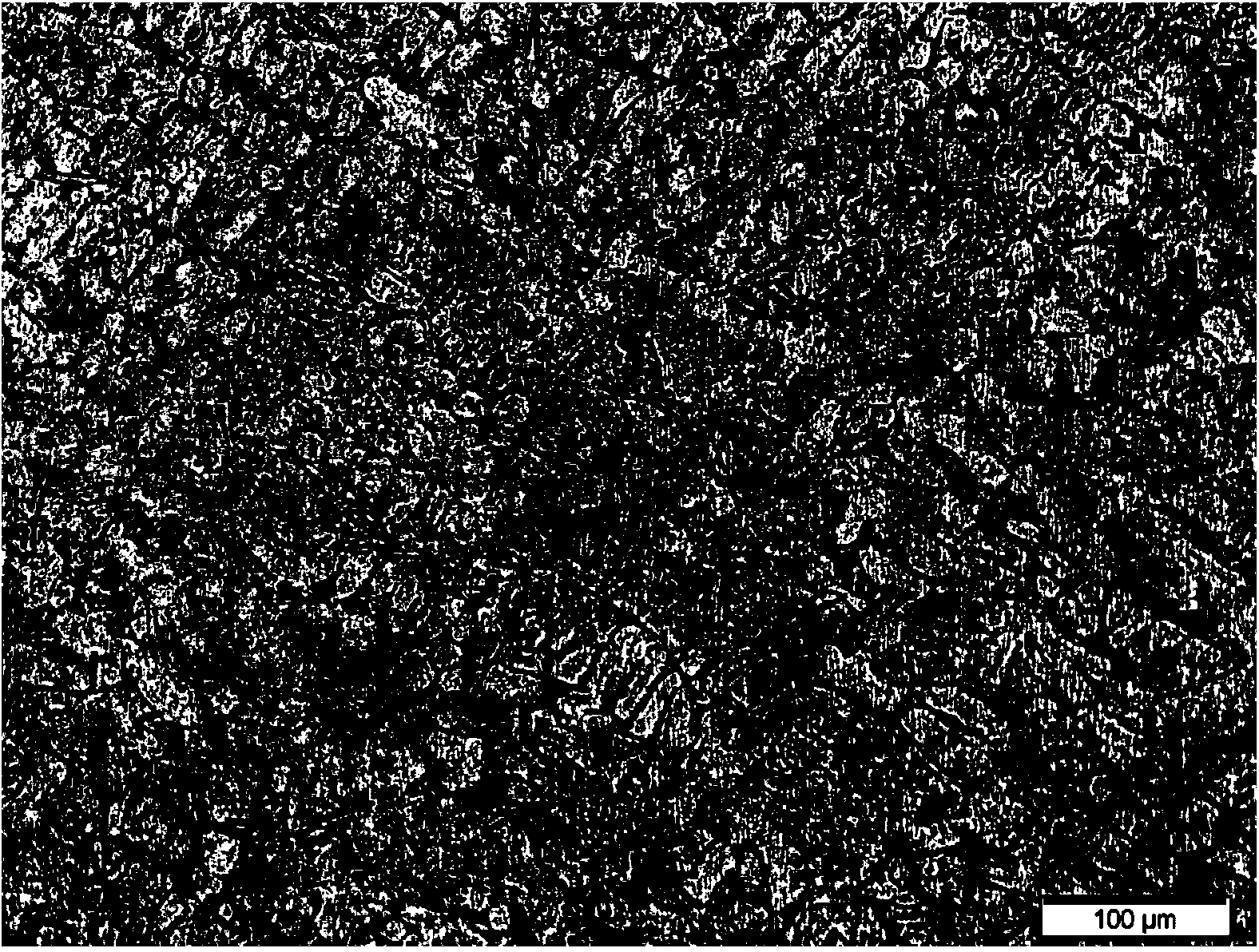

[0019] Specific embodiment 1: This embodiment is a modification agent for ADC12 aluminum alloy consisting of Al-5Ti-B master alloy and Al-10RE master alloy; the mass percentage of Ti in the Al-5Ti-B master alloy is 0.01 % to 0.06%; the mass percentage of B in the Al-5Ti-B master alloy is 0.002% to 0.012%; the mass percentage of RE in the Al-10RE master alloy is 0.2% to 1.0%.

[0020] The advantages of this embodiment: 1. The refinement effect of this embodiment is stable and not easy to decline; 2. This embodiment refines the α-Al dendrites and eutectic silicon in the ADC12 alloy structure, which improves the strength of the ADC12 aluminum alloy. Performance; 3. This embodiment solves the problems of severe splitting and poor mechanical properties of ADC12 aluminum alloy. The tensile strength is 230MPa-237MPa, the tensile strength is increased by 25%-30%, and the elongation is 3.0%-3.6%. Increased by 2 times to 2.6 times, expanding the scope of use of the ADC12 aluminum alloy;...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass percentage of Ti in the Al-5Ti-B master alloy is 0.02% to 0.04%; The mass percentage of B is 0.002% to 0.008%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the mass percentage of RE in the Al-10RE master alloy is 0.4%-0.8%. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com