Method and device for slab continuous casting using two pouring openings

A slab continuous casting and nozzle technology, which is used in casting equipment, casting melt containers, manufacturing tools, etc., can solve problems such as uneven temperature, and achieve the effects of improving fluctuation conditions, increasing continuous casting time, and reducing steel throughput.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

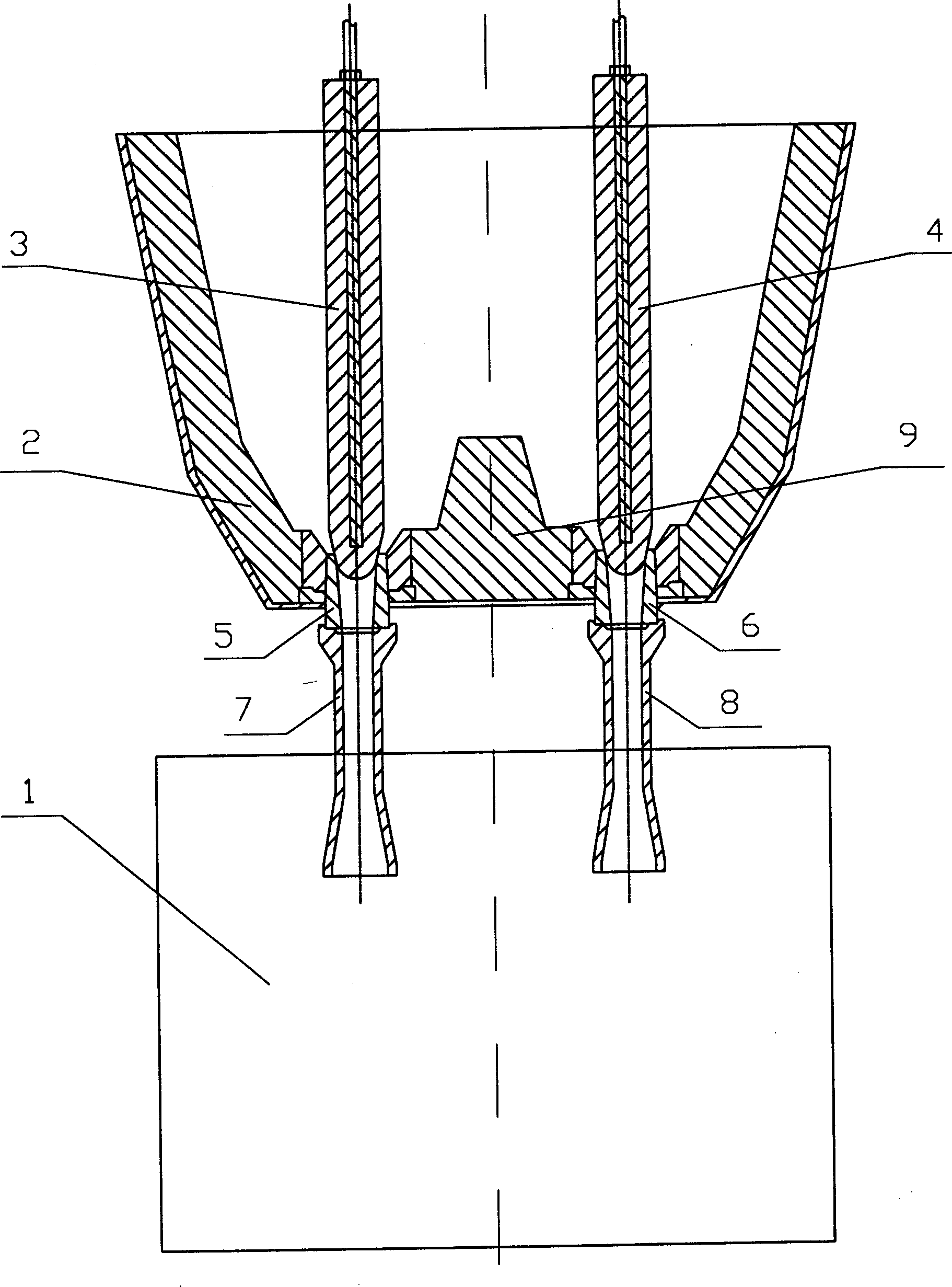

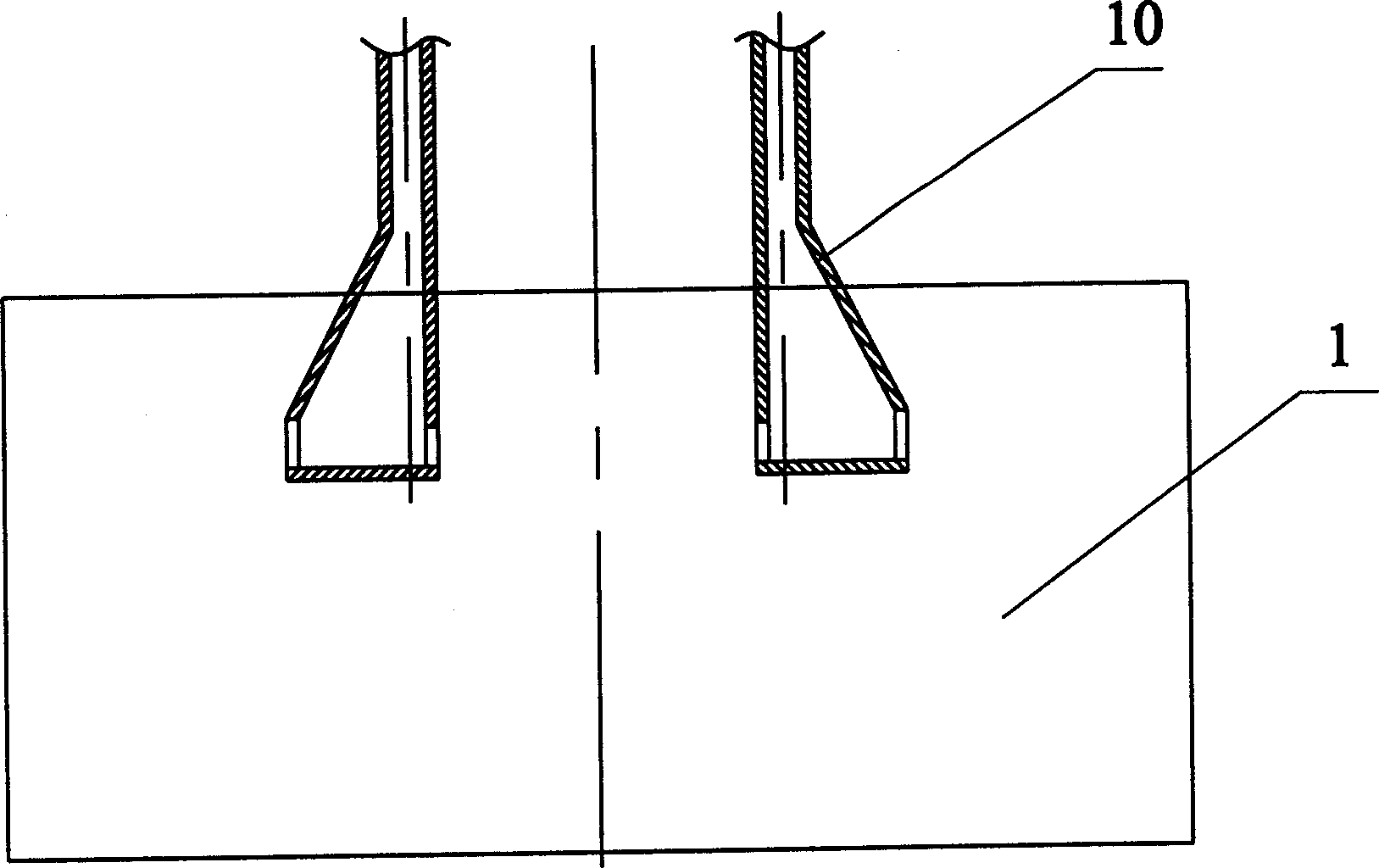

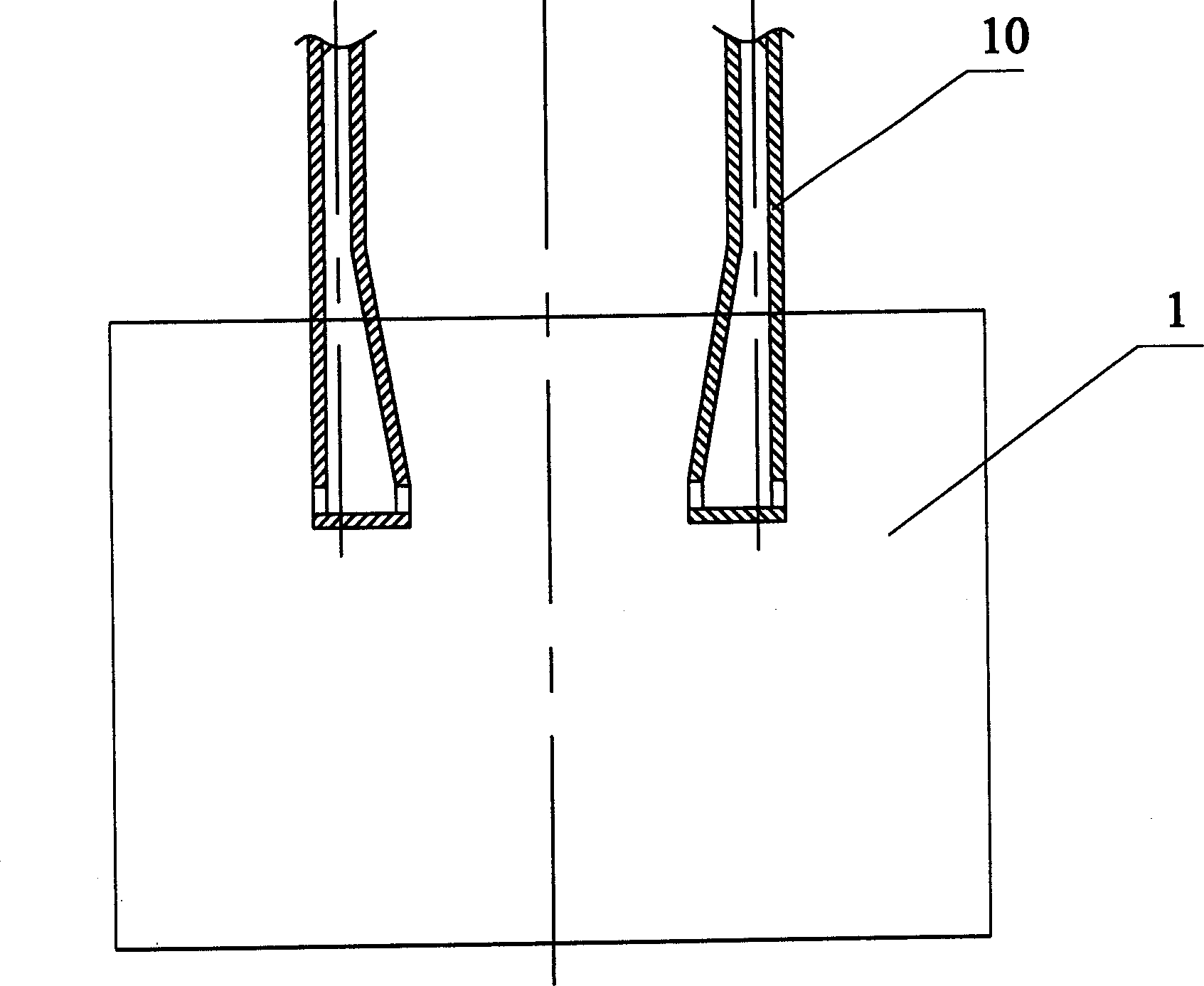

[0032] Such as figure 1 As shown, the method of the present invention is: insert two submerged nozzles 7, 8 into a slab continuous casting crystallizer 1 for pouring, each submerged nozzle 7, 8 is connected with an upper nozzle in the tundish 2 respectively 5 and 6 are connected, forming two independent injection channels between the tundish 2 and the crystallizer 1; above each upper nozzle 5 and 6, a stopper rod 3 and 4 are used to control the injection flow and In this way, the liquid level control of the crystallizer is realized.

[0033] The device of the present invention comprises a tundish 2, submerged nozzles 7, 8 and a crystallizer 1; two upper nozzles 5, 6 and corresponding stopper rods 3, 4 are arranged in the tundish 2; two Two submerged nozzles 7, 8, the submerged nozzles 7, 8 are connected with the upper nozzles 5, 6 in the tundish 2, and the submerged nozzles 7, 8 are inserted in the crystallizer 1; An intermediate weir 9 is set between the nozzles 5 and 6 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com