Forming mould and forming method of notebook face shell

A technology for forming molds and notebooks, which is applied in the field of injection molding molds and moldings for notebook covers, which can solve problems such as poor surface effects of carbon fiber plastic products, poor fluidity of carbon fiber composite materials, and products that cannot meet quality requirements, and achieve injection molding Low pressure, improved warpage, and reduced injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

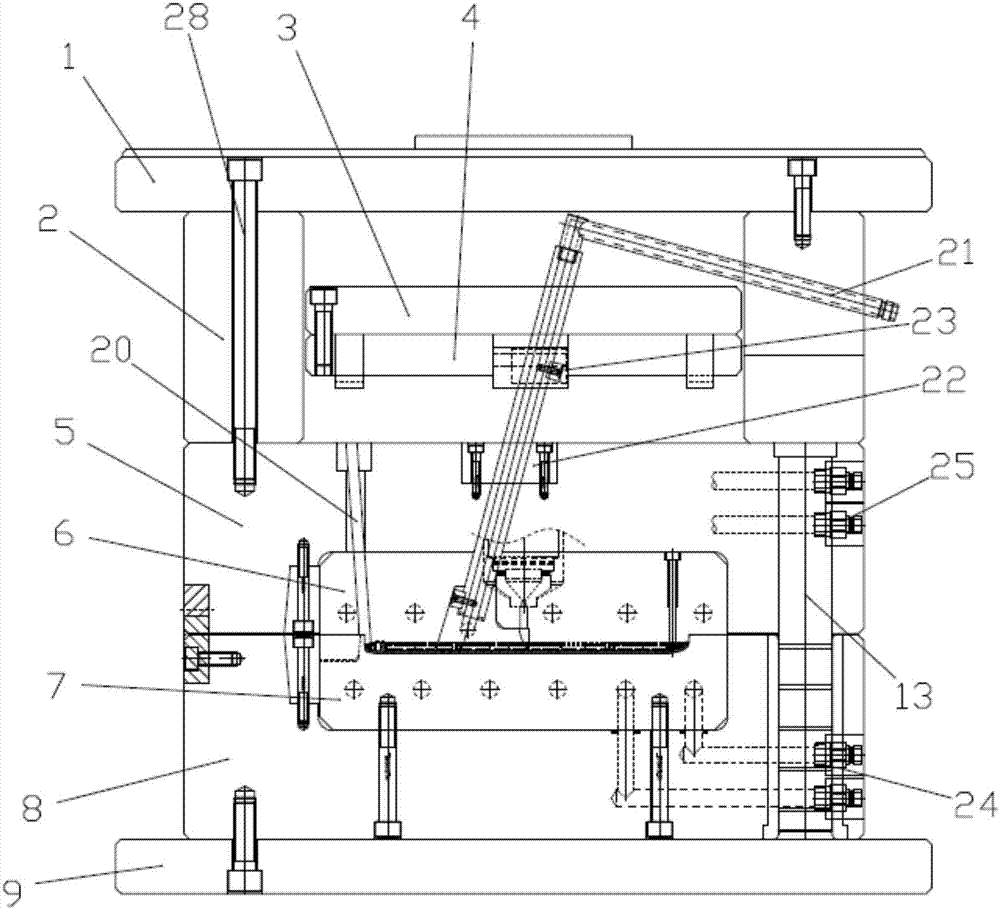

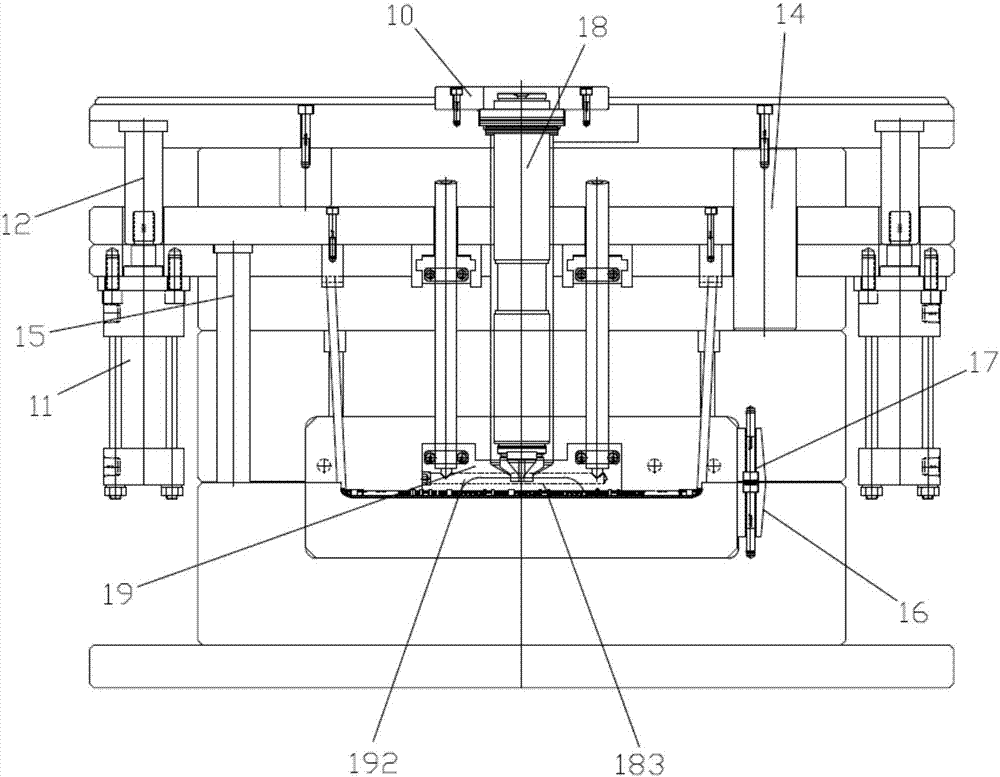

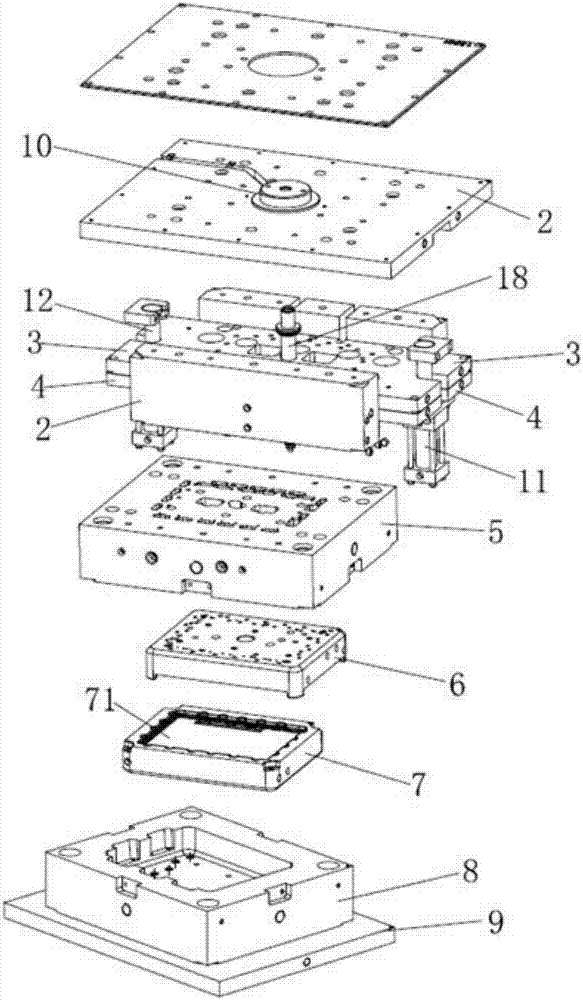

[0031] The molding die and molding method of the notebook cover of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0032] Such as figure 1 and figure 2 As shown, a molding die for a notebook cover according to an embodiment of the present invention includes a fixed mold part and a movable mold part, and the fixed mold part includes a fixed mold panel 1, a square iron 2, a thimble bottom plate 3, and a thimble panel from top to bottom. 4. The fixed template 5, the fixed mold core 6 and the hot nozzle 18, the square iron 2 is two pieces, which are respectively fixed on the lower sides of the fixed mold panel 1 by screws, the thimble bottom plate 3 and the thimble panel 4 are fixed up and down, and the movable mold The part includes the movable mold bottom plate 9, the movable template 8 and the movable mold core 7 from bottom to top, and the mold core 6 and the movable mold core 7 are respectively provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com