Reduction gearbox shell casting process

A casting process and reduction box technology, applied in the field of reduction box shell casting technology, can solve the problems of unreasonable design of gating system, unreasonable design of exhaust device, inability to process reduction box shell, etc. The effect of reducing cold isolation and porosity defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

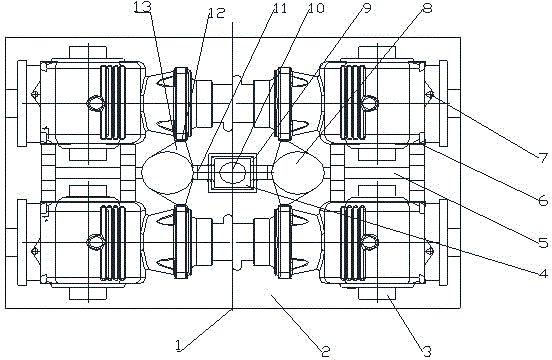

[0021] Such as figure 1 As shown, the present invention discloses a casting process for the gearbox housing, the process steps are as follows:

[0022] (1) Sand mix: mix molding sand and oil core sand as required;

[0023] (2) Mold preparation: when designing the mold, the mold includes sand box 1, sand mold 2, sand core 3 and pouring system 4;

[0024] The sand box 1, the sand mold 2 and the sand core 3 built in the sand mold together constitute the pouring cavity. There are four pouring cavities in matrix distribution, and the four pouring cavities are connected through the pouring system;

[0025] The gating system 4 includes a sprue 9, a runner 11 and a pair of auxiliary runners 5 respectively arranged between two adjacent casting cavities on both sides, and the casting cavity is at the flange of the input end of the gearbox housing It has an inner gate 12, and a pair of auxiliary inner gates 6 on both sides of the inner output end face of the gearbox housing; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com