Sand mold structure for integrally molded screw compressor case and manufacture and use method of sand mold structure

A screw compressor and casing technology, applied in the field of casting, can solve the problems of difficult processing, poor sealing, large overall length and size, etc., and achieve the effects of ensuring strength and sealing, short casing structure, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

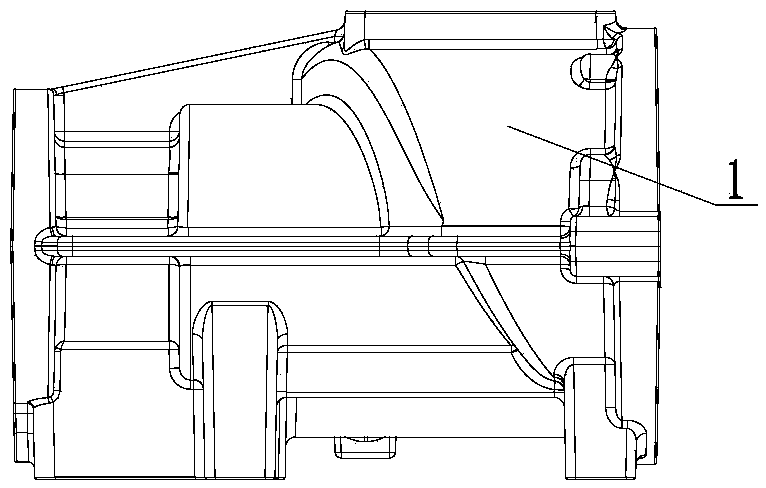

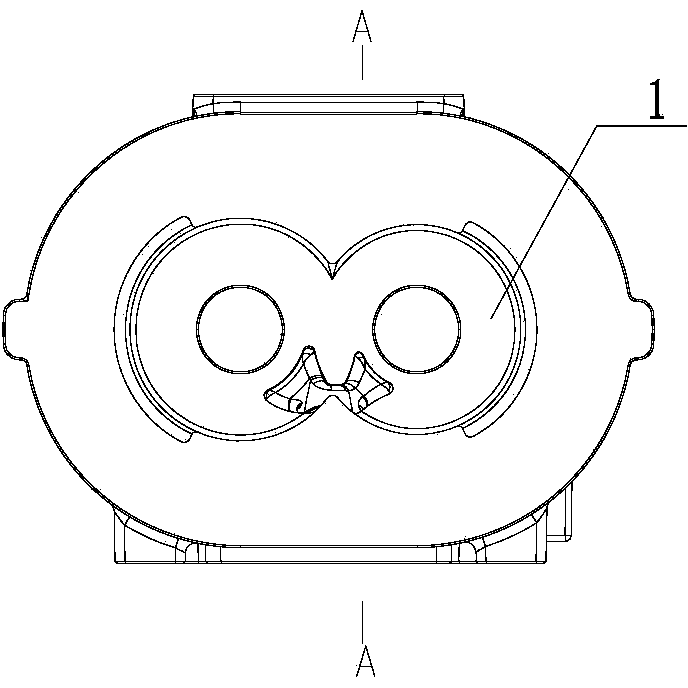

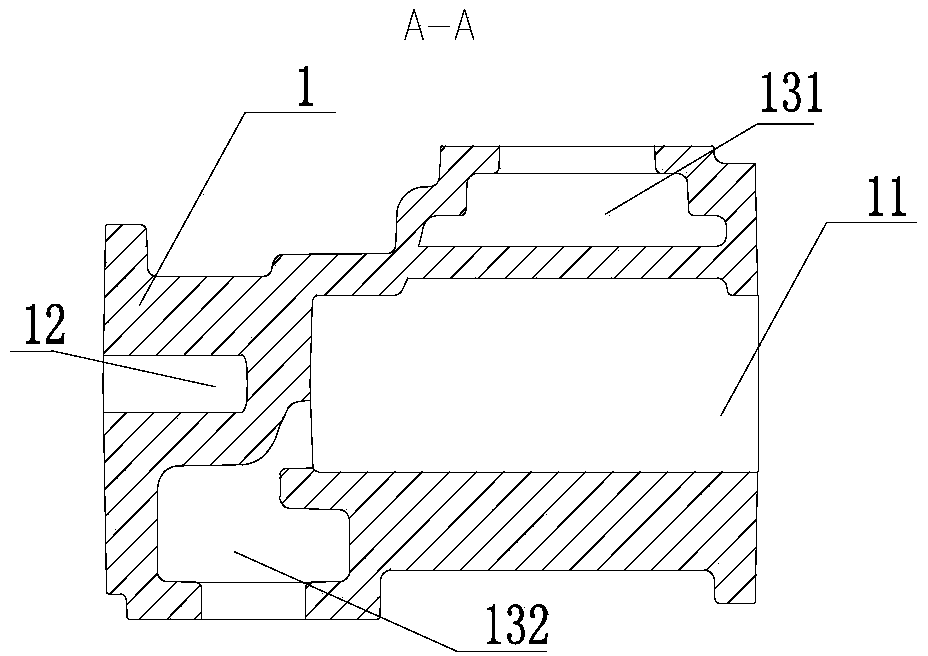

[0029] Such as figure 1 , 2 , 3, the main body of the casing 1 is columnar, and a large cavity 11 extending along its axis is opened inside it, and two cylindrical small cavity 11 is connected with the large cavity 11 and the axis is parallel to the axis of the large cavity 11. The cavity 12 is provided with two protrusions on its side wall, and the two protrusions are distributed on both sides of the large cavity and are respectively provided with medium-sized cavities, which are respectively the first medium-sized cavity 131 and the second medium-sized cavity 132 . Taking the axis of the large cavity 11 as the dividing line, when the large cavity 11 is placed horizontally, the first medium cavity 131 is located in the upper half of the casing 1, passing between the large cavity 11 and the small cavity 12 The communication holes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com