Method for mold-unloading and cooling thin and small injection molding part and part taking board

A cooling method and technology of injection molded parts, which are applied in the field of injection molding processing of injection molded parts, can solve problems such as easy deformation of parts, and achieve the effects of reduced manufacturing costs, reduced costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

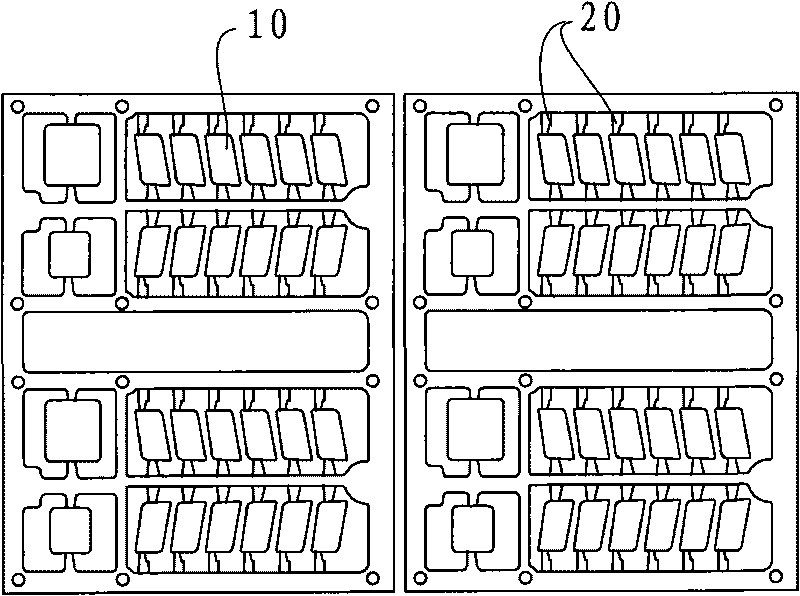

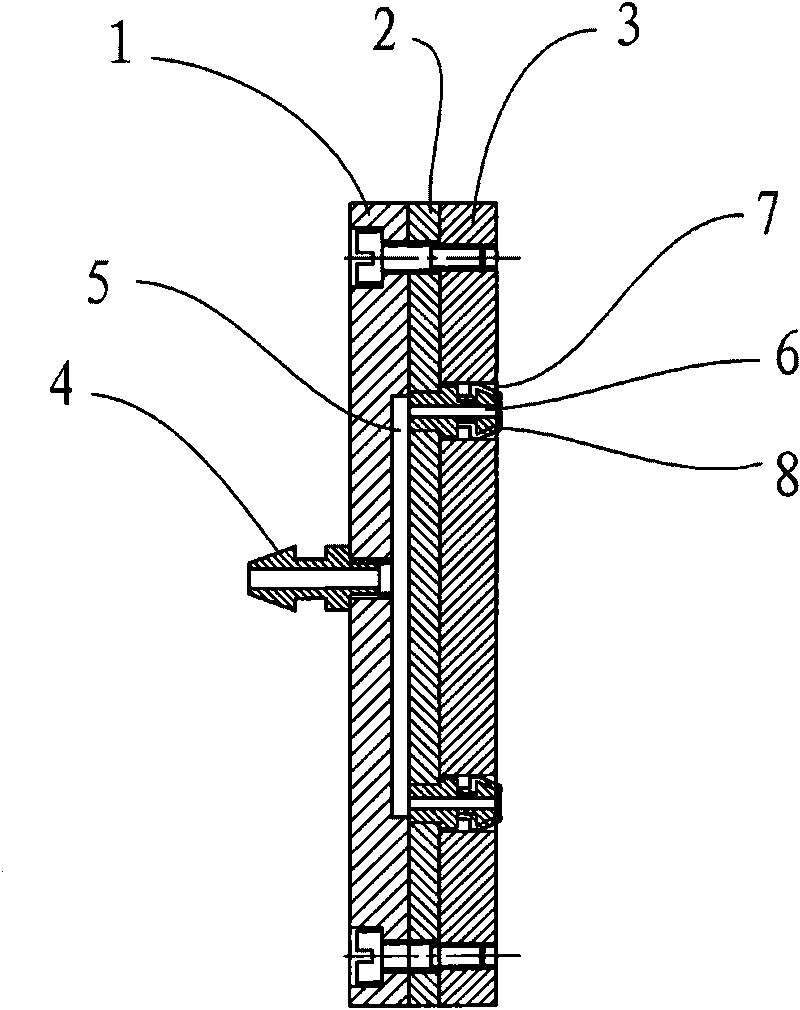

[0040] see Figure 4 , Figure 5 , Figure 6 and Figure 8 According to the present invention, a pick-up plate 100 for the above-mentioned method of opening and cooling thin injection molded parts includes a channel plate 120 with a vacuum suction tube 110 and a grooved channel 121 that is sequentially pasted and assembled, and is provided with a communication channel. The vacuum suction plate 140 of the suction piece nozzle 130 of the grooved channel 121 and the fixed plate 160 provided with the suction piece nozzle through hole 161, the suction piece nozzle 130 is covered with a flexible plastic suction cup 170, the above structure is the existing pick-up plate structure; the invention point of the present invention is to recombine the device for spraying cold air to the connection position of the injection molded part and the gate with the pick-up plate, and the manipulator can complete the work of local air cooling and pick-up in one action, which not only reduces the ma...

Embodiment 2

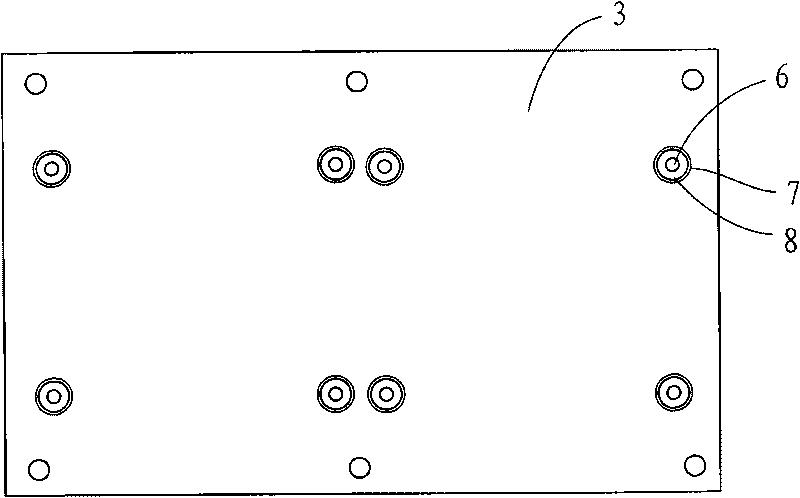

[0043] Figure 7 Shown is another embodiment of the pick-up plate of the present invention. The pick-up plate 200 of this embodiment also includes a channel plate 220 that is sequentially fitted and assembled with a vacuum suction tube 210 and a grooved channel 221, and is provided with a communicating groove. The vacuum suction plate 240 of the suction part of the type channel 221 and the fixed plate 260 that is provided with the through hole 261 of the suction part. The connection position of the nozzle is provided with a nozzle hole 262; the position corresponding to the nozzle hole 262 on the vacuum suction plate 240 is provided with an air chamber 241 through the plate thickness containing the nozzle hole 262; The through hole 222 of the air chamber 241 of the plate 240 is also provided with an air pipe joint 223 on the through hole 222 of the channel plate 220 .

[0044] The difference between this embodiment and the first embodiment is that the slot-shaped air chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com