Casting method of water-cooling aluminum engine base embedded with support

A water-cooling and frame technology, applied in the directions of rotors, cylinders, heat exchange equipment, etc., can solve the problems of easy cracking, short service life of motor aluminum frame, poor strength of motor aluminum frame, etc., to avoid unevenness, avoid The effect of directly scouring damage and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

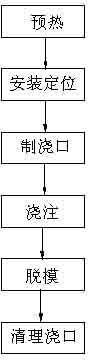

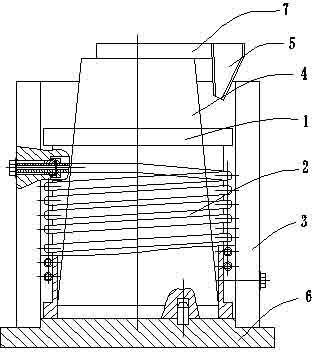

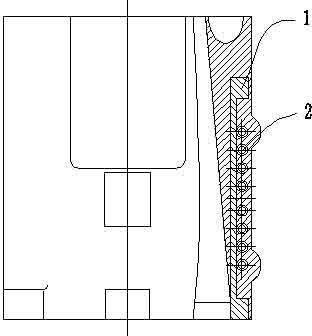

[0020] See Figure 1 ~ Figure 3 : The casting method of the water-cooled aluminum frame with built-in bracket shown, selects the aluminum alloy of ZL107 as material to cast the water-cooled aluminum frame with built-in bracket, and the casting method includes the following steps:

[0021] (a) Preheating, the cooling copper pipe 2 is wound on the cylindrical iron support 1, and the outer wall of the iron support 1 near the upper and lower ends is provided with protrusions 1a in the circumferential direction, and the cooling copper pipe 2 is wound on the iron support 1. The iron bracket 1 of the pipe 2 is preheated at a heating temperature of 200°C, and the mold is preheated at a heating temperature of 250°C;

[0022] (b) Installation and positioning, put the iron bracket 1 around the cooling copper pipe 2 into the outer mold 3 of the mold, the mold is composed of the outer mold 3, the core tire 4 and the bottom plate 6, wherein the outer mold 3 Fixed on the bottom plate 6, the...

Embodiment 2

[0028] See Figure 1 ~ Figure 3 : The casting method of the water-cooled aluminum frame with built-in bracket shown, selects the aluminum alloy of ZL107 as material to cast the water-cooled aluminum frame with built-in bracket, and the casting method includes the following steps:

[0029] (a) Preheating, the cooling copper pipe 2 is wound on the cylindrical iron support 1, and the outer wall of the iron support 1 near the upper and lower ends is provided with protrusions 1a in the circumferential direction, and the cooling copper pipe 2 is wound on the iron support 1. The iron bracket 1 of the pipe 2 is preheated at a heating temperature of 250°C, and the mold is preheated at a heating temperature of 300°C;

[0030] (b) Installation and positioning, put the iron bracket 1 around the cooling copper pipe 2 into the outer mold 3 of the mold, the mold is composed of the outer mold 3, the core tire 4 and the bottom plate 6, wherein the outer mold 3 Fixed on the bottom plate 6, the...

Embodiment 3

[0036] See Figure 1 ~ Figure 3 : The casting method of the water-cooled aluminum frame with built-in bracket shown, selects the aluminum alloy of ZL107 as material to cast the water-cooled aluminum frame with built-in bracket, and the casting method includes the following steps:

[0037] (a) Preheating, the cooling copper pipe 2 is wound on the cylindrical iron support 1, and the outer wall of the iron support 1 near the upper and lower ends is provided with protrusions 1a in the circumferential direction, and the cooling copper pipe 2 is wound on the iron support 1. The iron bracket 1 of the pipe 2 is preheated at a heating temperature of 300°C, and the mold is preheated at a heating temperature of 350°C;

[0038] (b) Installation and positioning, put the iron bracket 1 around the cooling copper pipe 2 into the outer mold 3 of the mold, the mold is composed of the outer mold 3, the core tire 4 and the bottom plate 6, wherein the outer mold 3 Fixed on the bottom plate 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com