Method for casting brass ware

A technology of copperware and components, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of difficult separation of products and cores, easy deformation and damage of wooden molds, and solve the problem of excessive cooling of copper liquid , low cost, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

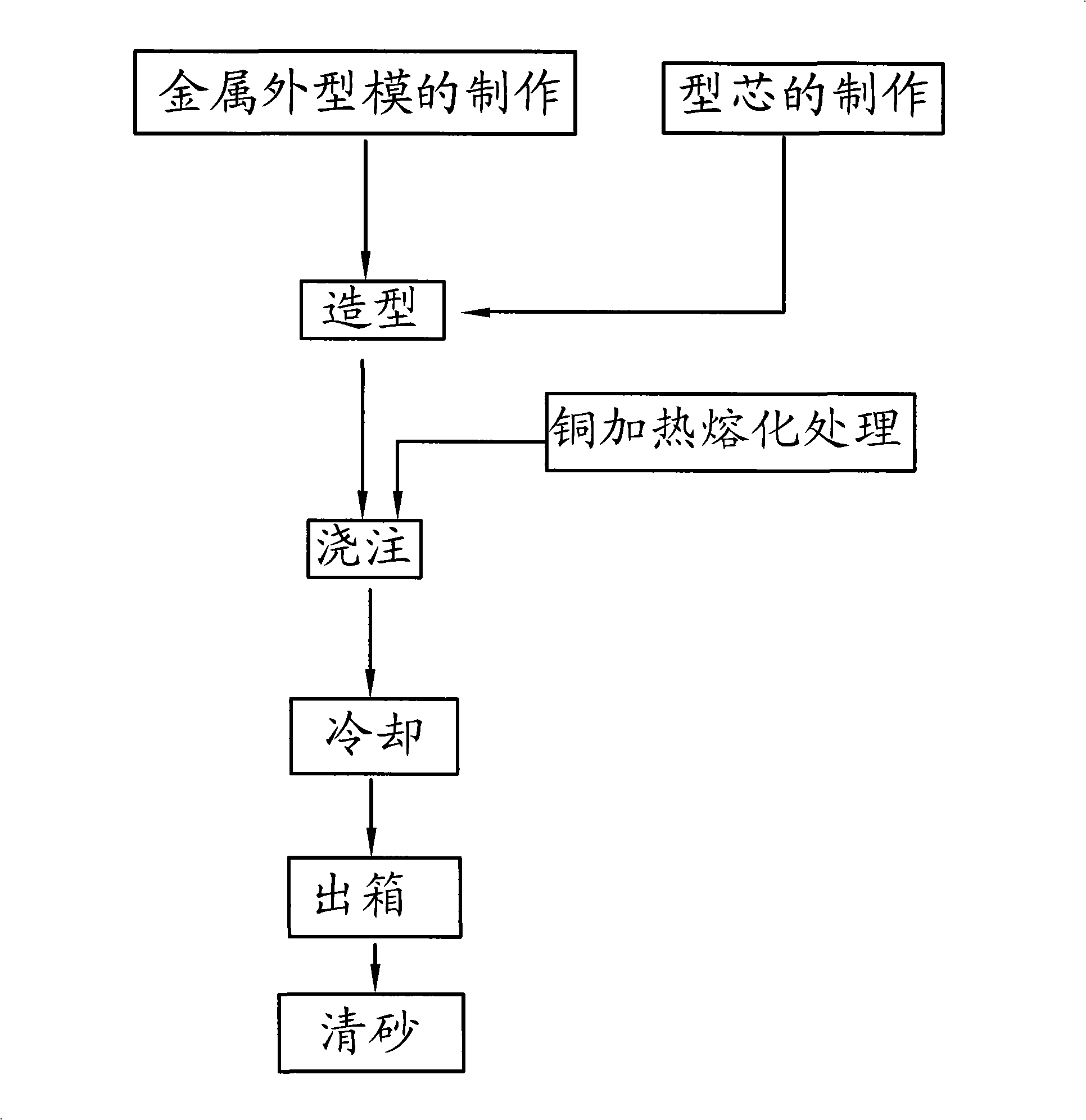

[0023] like figure 1 The shown flow process, a casting method of a copper device, comprises the following steps in sequence:

[0024] 1. Production of metal exterior molds:

[0025] According to the shape of the product, the machining center is used to make the metal shape mold of the product. According to the shape and size of the product, multiple products can be made in one pair of molds. The size of the mold needs to be increased on the basis of the original size of the casting according to the shrinkage rate, and the machining allowance is reserved for the table that needs to be cut. When making sand molds, it is necessary to consider how to separate the upper and lower sand boxes to take out the shape mold, and also consider where the copper water flows in, and how to fill the cavity to obtain high-quality castings. The metal exterior mold is divided into two sides, and the two sides are the symmetrical halves of the product. If there is a trademark on the product, it ...

Embodiment 2

[0051] During the heating and melting process of copper, the temperature of copper melting is 1250° C., and the temperature of pouring is 1100° C. The other technological process is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0053] During the heating and melting process of copper, the temperature of copper melting is 1290°C, and the temperature of pouring is 1160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com