Die-casting die for manufacturing damping tower and vacuum die-casting method of damping tower

A technology of vacuum die-casting and damping tower, which is applied in the field of vacuum die-casting molds and vacuum die-casting, and can solve problems such as complex design of fixed mold structure, complex setting of gating system, complex design of vacuum die-casting mold structure of shock absorbing tower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

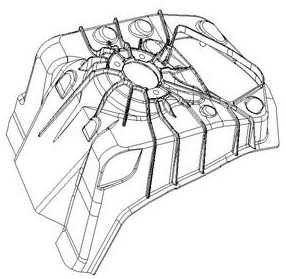

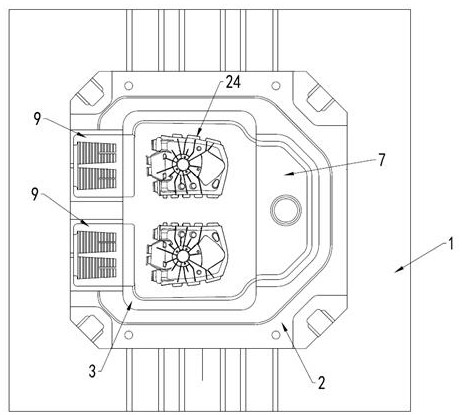

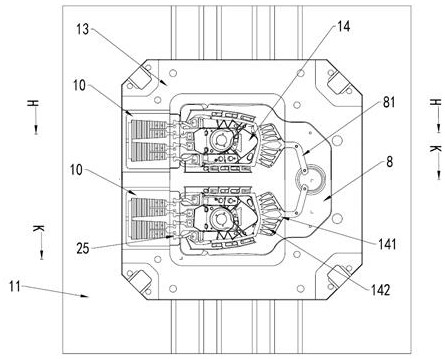

[0022] Such as Figure 2-Figure 6 As shown, the vacuum die-casting mold used to make the shock tower provided by this embodiment includes a fixed mold, a movable mold, an ejection system located in the movable mold, and a cooling system for cooling the mold and the casting. The system can eject the casting from the mold after the mold is opened; the fixed mold includes a fixed mold base 1, a fixed mold frame 2 and two fixed mold inserts 3, and the movable mold includes a movable mold base 11, The movable mold frame 13 and two movable mold inserts 14 corresponding to and matched with the fixed mold insert 3; the two fixed mold inserts 3 are installed in the middle of the fixed mold frame 2, and the two movable mold inserts 14 are installed in the In the middle part of the movable mold frame 13, the two fixed mold inserts 3 and the movable mold insert 14 form two cavities matching the shape and size of the casting after the mold is closed; in the fixed mold mold frame 2, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com