Method and device for producing thick-walled plastic components, in particular optical components

A technology for plastic parts and plastics, applied in the field of manufacturing plastic parts, can solve the problems of neglect and increased material consumption, and achieve high quality and reduce separation marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

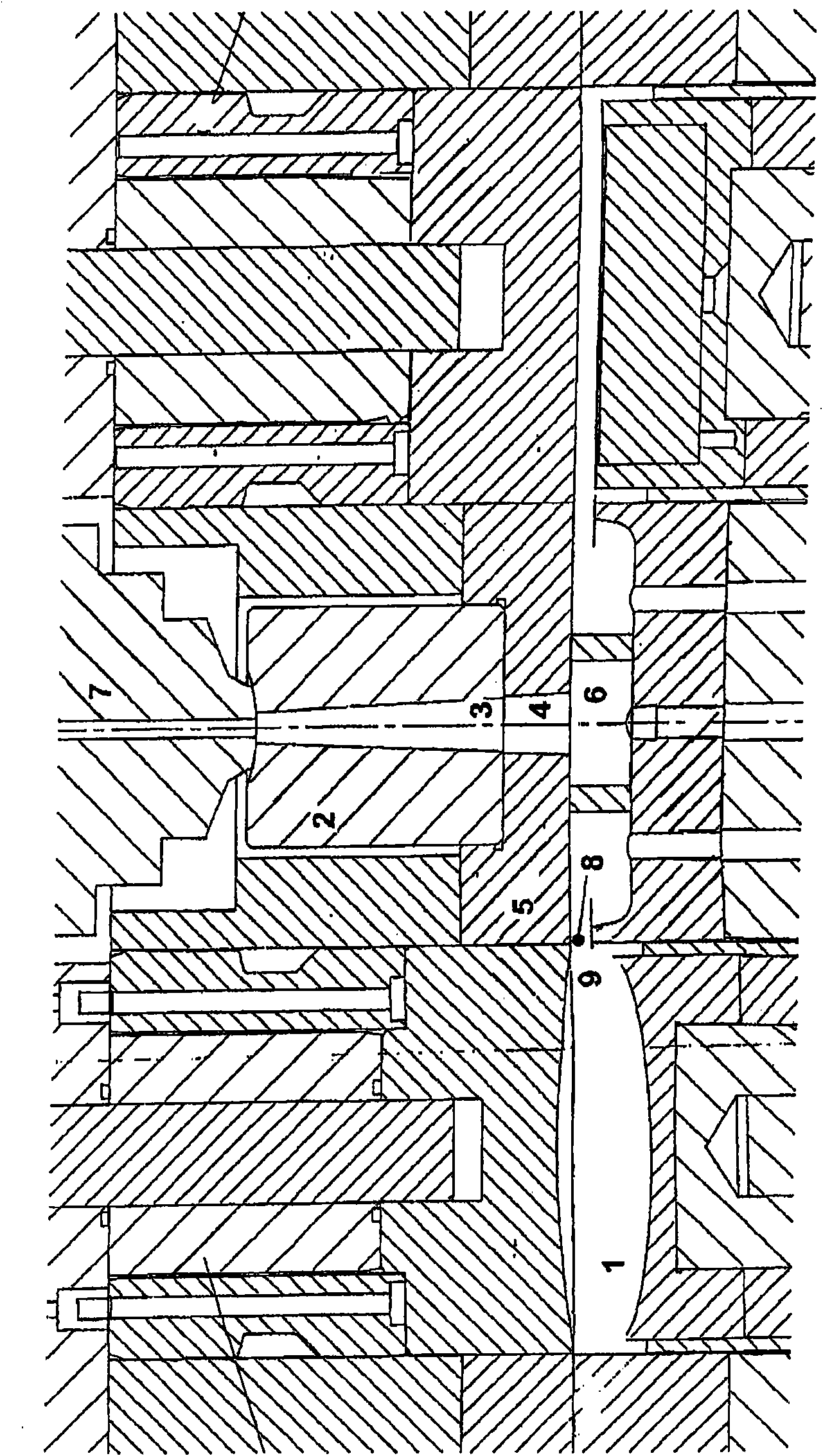

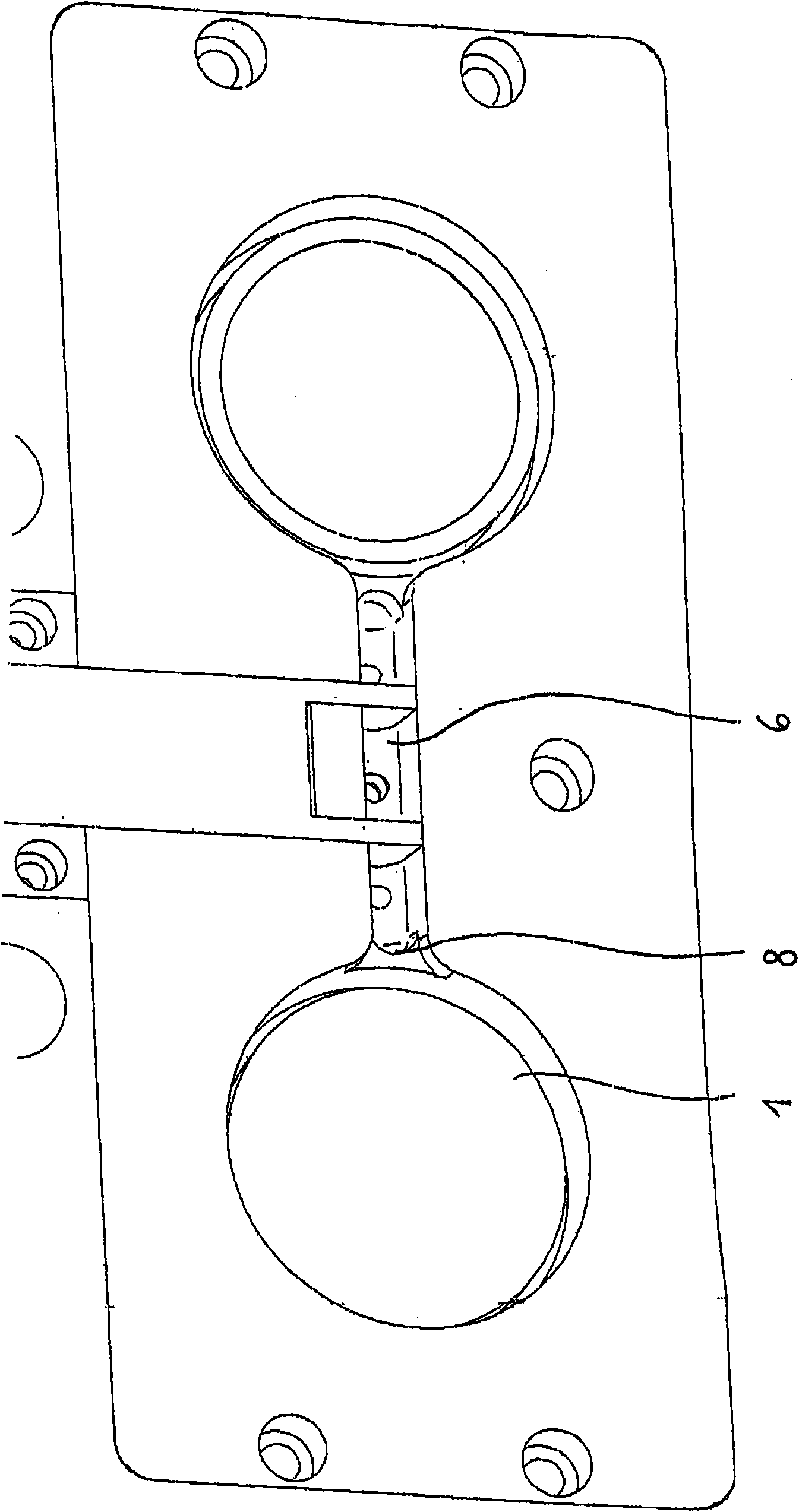

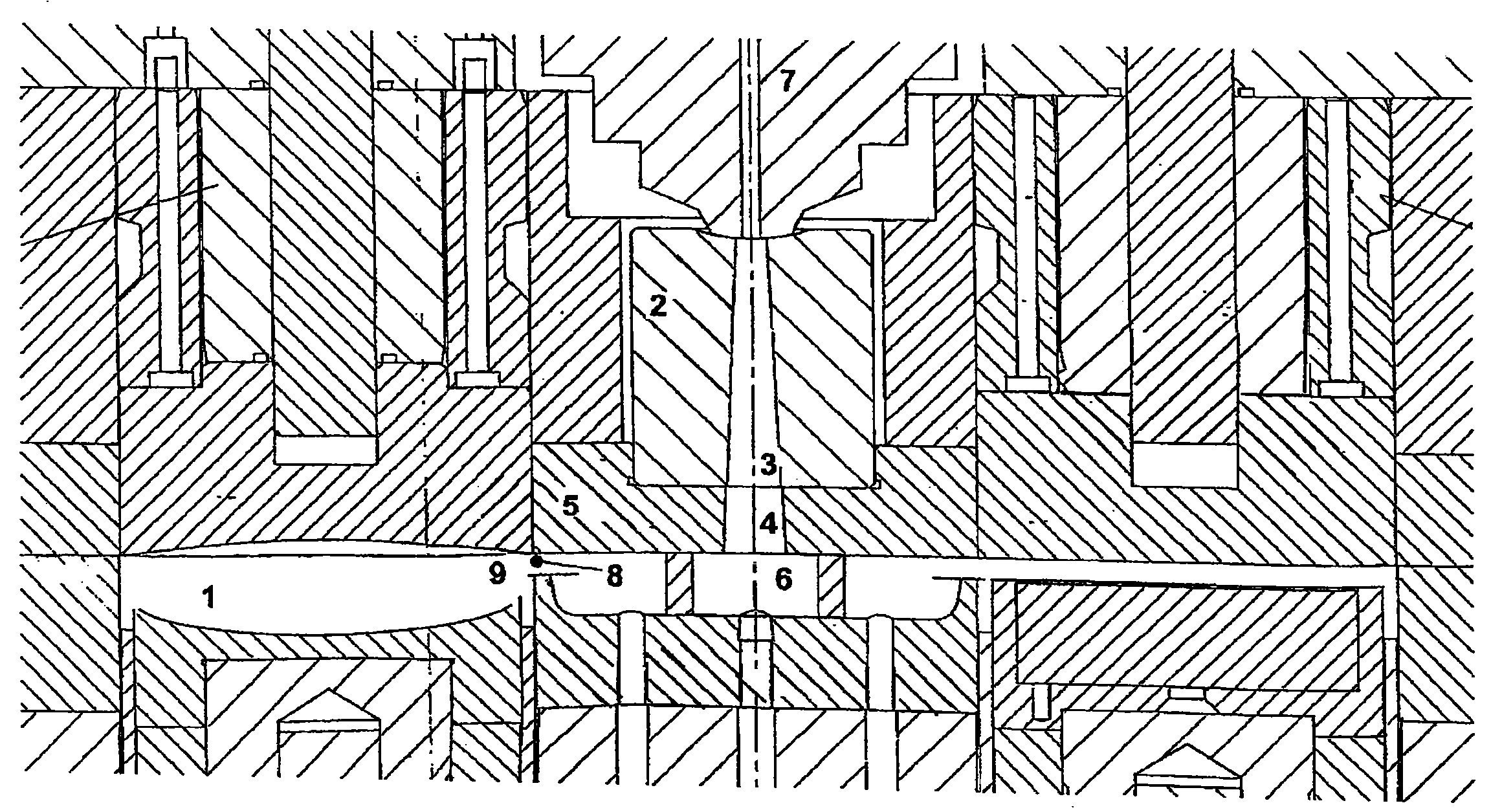

[0023] The injection-molding tool described in the figures is used for the manufacture of transparent parts, especially optical lenses, from synthetic materials. The injection-molding tool is composed of several parts defining a cavity 1 shaping the part to be manufactured.

[0024] In the exemplary embodiment shown, the injection-molding tool comprises a sprue bushing 2 with a conical channel 3 . This channel 3 leads to a further, likewise conical, channel part 4 , which passes through the plate-shaped tool part 5 and leads to a flow channel 6 . Through the runner 6, the plastic melt passing from the nozzle 7 of the injection-molding machine with the injection-molding screw or other feeding means to the sprue bushing is introduced into the cavity 1 . For the runner 6, cold runners are preferably considered.

[0025] The gate 8 for the melt is arranged at the edge of the cavity 1 such that the gate 8 is located at the periphery of the disc-shaped plastic part, thus on the na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com