Device and method for preparing metal semi-solid slurry

A semi-solid slurry and metal technology, applied in the field of metal rheological molding, can solve the problems of staying, complex production, poor slurry quality, etc., and achieve the effects of high production efficiency, strong applicability and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The core of the preparation method of the metal semi-solid slurry of the present invention is to add solid particles of the same composition-self-inoculant during the solidification process of the metal alloy liquid, and its specific steps are:

[0017] (1) Process a small metal block with the same composition as the alloy to be processed - the self-inoculant, and introduce the self-inoculant into the melted alloy melt;

[0018] (2) Control the temperature of adding self-inoculant and pouring temperature of the melt to be 50-150°C above the liquidus temperature of the alloy;

[0019] (3) Carry out conventional melt treatment after melting of the inoculant.

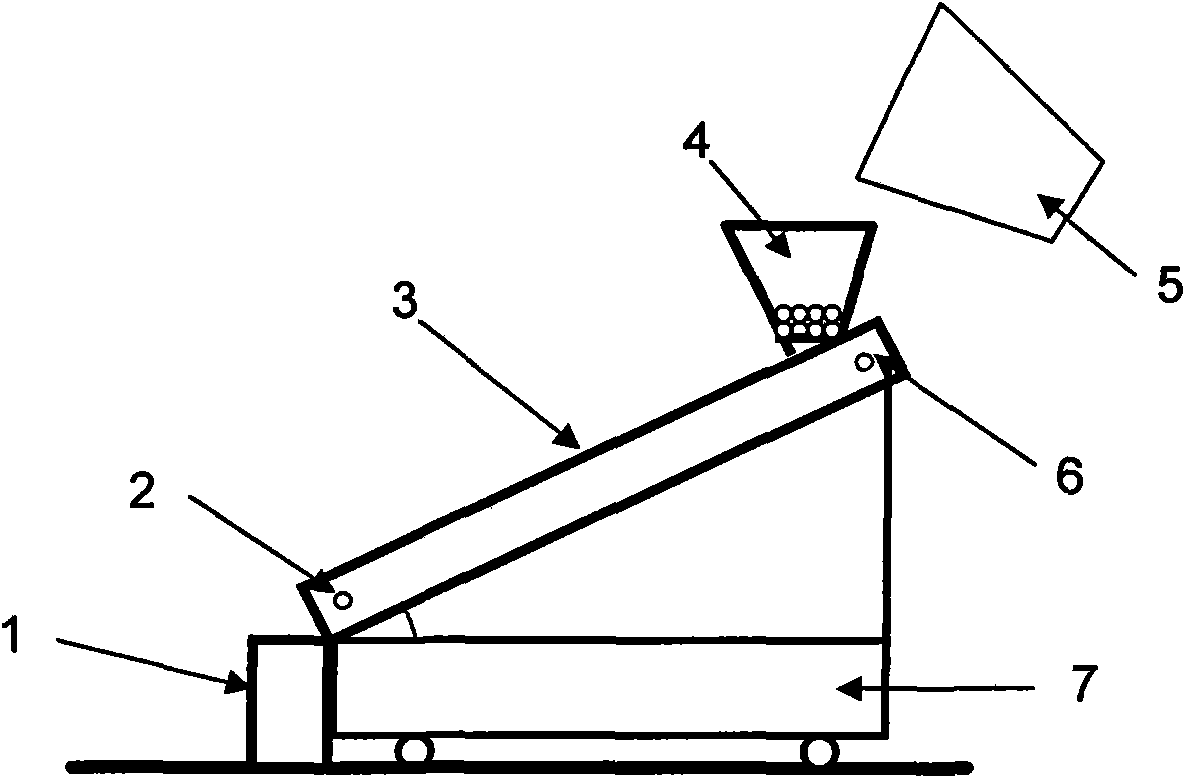

[0020] In the method for rapidly preparing the metal semi-solid slurry of the present invention, the self-inoculant can be placed at the bottom of the sprue cup 4, or the self-inoculant can be added into the ladle 5 with stirring.

[0021] The alloy processed and treated by the method of the present invention is an...

Embodiment 1

[0024] The alloy grade used in this example is AZ91D, and its alloy composition is (mass percentage, the same below): Al 8.3-9.7%, Zn 0.35-1.0%, Mn 0.15%, Si≤0.10%, Cu≤0.030%, Fe 0.005%, Ni≤0.02%, and the rest is Mg.

[0025] In this embodiment, the method of placing the self-inoculant in the sprue cup 4 is suitable for continuous batch production of high-quality semi-solid slurry.

[0026] In practice, a part of the metal alloy with the same composition is mechanically cut into small pieces of metal of the same size for use (called self-inoculant), about 10mm×10mm×10mm; then another part of the metal with the same composition The alloy is melted, and after melting, it is subjected to conventional melt treatment, such as degassing and refining. At the same time, the processed self-inoculant is placed on the bottom of the sprue cup 4 . Then adjust the melt temperature to about 680°C for pouring, and open the cooling water outlet 2 and inlet 6; use the ladle 5 to pour into the...

Embodiment 2

[0028] The grade of alloy used in this example is AZ91D, and its alloy composition is: Al 8.3-9.7%, Zn0.35-1.0%, Mn 0.15%, Si≤0.10%, Cu≤0.030%, Fe 0.005%, Ni≤0.02 %, the rest is Mg.

[0029] This embodiment adopts the method of adding the self-inoculant into the ladle, which is suitable for small-batch, intermittent high-quality semi-solid slurry production.

[0030] The implementation process of this example is similar to Example 1, the difference is that the size of the self-inoculant agent is about 5mm×5mm×5mm; the self-inoculant is not placed at the bottom of the sprue cup, but is added to adjust the temperature 680-710 ℃ in the melt, that is, add it in the ladle, the amount of addition is 5% of the mass of the melt, and stir for 5 seconds; then pour it into the sprue cup that does not contain the inoculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com