Electrostatic eliminating, chip removing and dust sucking device for lost foam casting forming machine

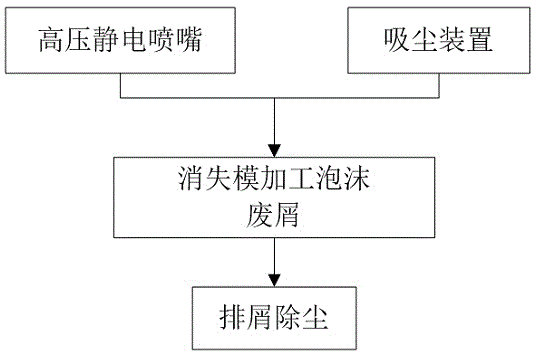

A technology of lost foam casting and vacuum hood, which is applied in the direction of electrostatic cleaning, dust removal, cleaning methods and utensils, which can solve the problems of not being able to prevent waste chips from splashing and pasting, and achieve effective foam cutting and dust removal effects and high economic benefits , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for dust removal and vacuuming of high-pressure ion nozzles will be further described in detail below in conjunction with the accompanying drawings and specific examples, but this is not intended to limit the present invention.

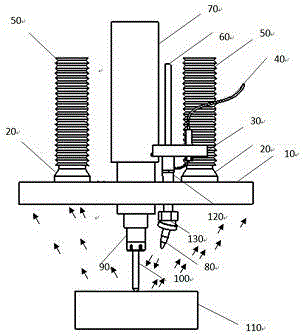

[0020] see figure 1 , including the processing spindle 90 spindle head and the cutter head 100 installed on the processing spindle, the nozzle is connected with the air pipe 60 inside the main shaft, the air pipe 80 is connected with the air compressor, and the rotation angle of the ball joint 130 is adjusted properly and then locked. The adopted trachea 60 has an inner diameter of 8 mm. The high-pressure ion nozzle fixes the ion differential generating device through the high-pressure ion support, and the ions generated by the ion needle are blown out with the high-speed airflow to blow chips. The size of the airflow is determined by adjusting the flow rate of the air compressor.

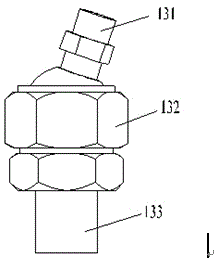

[0021] see figure 2 , The nozzle 80 connects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com