Method for lost foam casting of composite two-liquor bimetallic hammerhead of crusher

A technology of lost foam casting, double liquid and double metal, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., which can solve the problems of improvement, difficulty in control, and no provision of molten metal pouring temperature, etc., and achieve simple production process and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] It is determined that the material of the hammer head part 5 is a high-chromium white cast iron (mainly to improve the wear resistance of the hammer head), and its chemical composition (weight percentage) is: 2.6%C, 15%Cr, 0.5%Mn, 0.5%Si , 0.3%Mo, 0.3%Cu, 0.06%P, 0.06%S, and the rest is Fe.

[0021] Hammer handle part 4 is made of carbon steel (to ensure that the hammer handle has high toughness), and its chemical composition (weight percentage) is: 0.2%C, 0.5%Mn, 0.3%Si, 0.06%P, 0.06%S, and the rest are Fe.

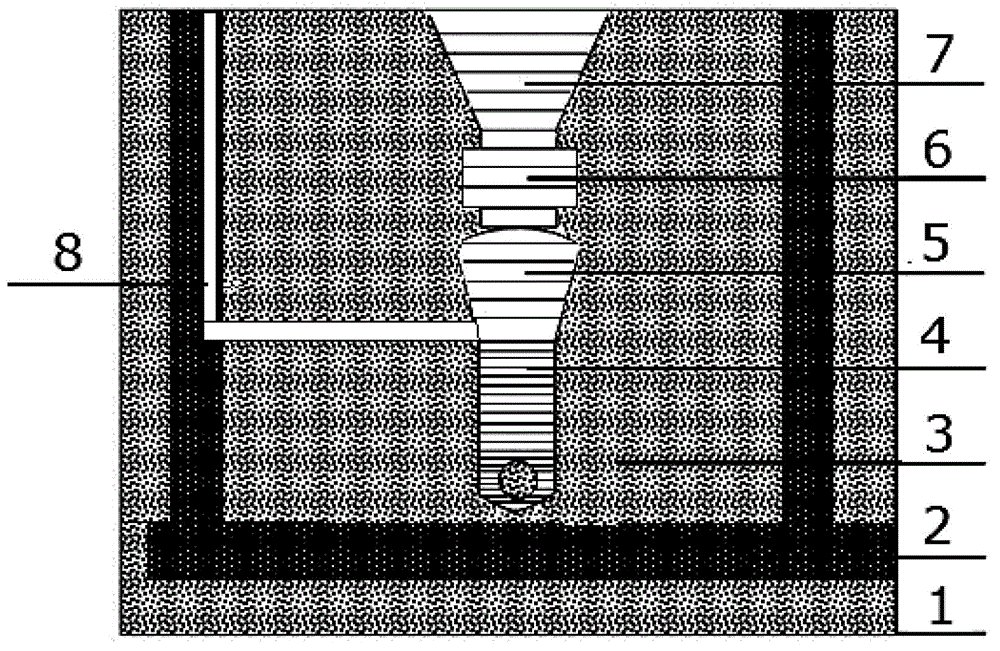

[0022] Such as figure 1 As shown, the foam plastic coated with paint (the thickness of the paint is about 1-2mm, and the paint is Guilin No. 5) is made into a crusher hammer head shape and embedded in the dry sand 2 of the sand box 1, and passed through the sand box in the sand box. The vacuum pipeline 2 is evacuated to a vacuum degree of 0.06MPa;

[0023] Calculate and weigh the above-mentioned high-chromium cast iron and carbon steel smelting raw materials re...

Embodiment 2

[0030] The present embodiment method step is identical with embodiment 1, just wherein some processing parameters are different:

[0031] The chemical composition (percentage by weight) of high chromium white cast iron is: 4.0%C, 35%Cr, 1.50%Mn, 1.5%Si, 1.5%Mo, 1.5%Cu, 0.3%P, 0.2%S, and the rest is Fe. The chemical composition (percentage by weight) of carbon steel is: 0.6%C, 1.50%Mn, 1.5%Si, 0.25%P, 0.28%S, and the rest is Fe.

[0032] Vacuum the sand box to a vacuum of 0.4Mpa.

[0033] The pouring temperature of high chromium cast iron is controlled at 1400°C; the pouring temperature of carbon steel is controlled at 1600°C.

[0034] In the heat treatment process, the temperature is raised to 1000°C at a heating rate of 50°C / hour. According to the maximum wall thickness of the hammer head of 60mm, the holding time at this temperature is determined to be 2 hours.

[0035] In the tempering process, the annealing temperature is 300°C, the heating rate is also controlled at 50°...

Embodiment 3

[0038] The present embodiment method step is identical with embodiment 1, just wherein some processing parameters are different:

[0039] The chemical composition (percentage by weight) of high chromium white cast iron is: 3.2%C, 25%Cr, 0.8%Mn, 0.7%Si, 1.0%Mo, 0.13%P, 0.13%S, and the rest is Fe.

[0040]The chemical composition (weight percentage) of carbon steel is determined as: 0.45%C, 0.8%Mn, 0.6%Si, 0.10%P, 0.07%S, and the rest is Fe.

[0041] Vacuum the sand box to a vacuum of 0.09Mpa.

[0042] The pouring temperature of high chromium cast iron is controlled at 1380°C; the pouring temperature of carbon steel is controlled at 1580°C.

[0043] In the heat treatment process, the temperature is raised to 950°C at a heating rate of 80°C / hour. According to the maximum wall thickness of the hammer head of 40mm, the holding time at this temperature is determined to be 1.5 hours.

[0044] In the tempering process, the annealing temperature is 300°C, the heating rate is also con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com