Lost-foam casting process for cylinder body and cylinder cap of diesel engine and gasoline engine

A technology of lost foam casting and gasoline engine, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of heavy casting weight, high raw material consumption, high labor intensity, etc., and achieves reduced labor intensity, high dimensional accuracy, and economical savings. The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

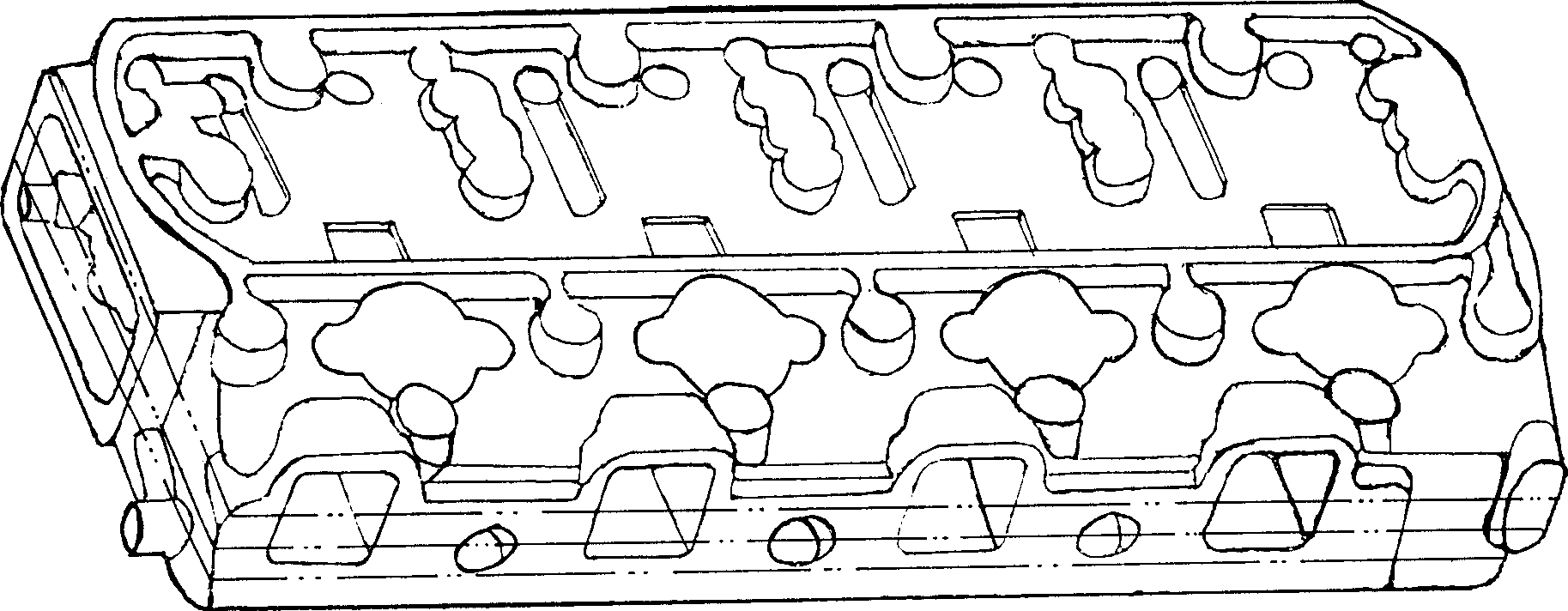

[0038] Such as figure 1 shown.

[0039] A kind of diesel engine, gasoline engine cylinder head lost foam casting process, it comprises the following steps:

[0040] a. Divide the diesel engine, gasoline engine cylinder block or cylinder head to be cast into several splicing blocks or pieces, the cylinder head can be divided into such as figure 1 The four-piece structure shown in the figure (the double dotted line in the figure indicates the cutting surface), and the cylinder body can be divided into eight pieces or eight pieces, and each diesel engine, gasoline engine cylinder block or cylinder head after cutting the splicing block or The number and direction of the slices can be cut from the angle that is most conducive to pouring and splicing; then according to the shape and internal structure of the split slices or blocks, the same mold cavity as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com