High manganese steel Sic ceramic particles composite preparation method

A technology of composite materials and high manganese steel, which is applied in the field of preparation of high manganese steel-based ceramic particle composite materials, can solve the problems of high manganese steel not being wear-resistant, so as to improve the overall strength and hardness, prolong life, and improve wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

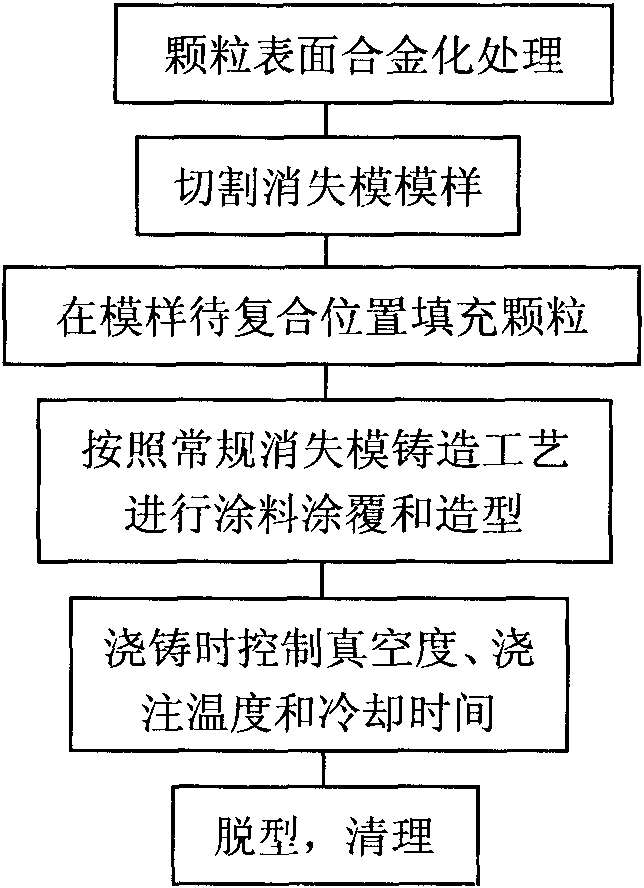

Method used

Image

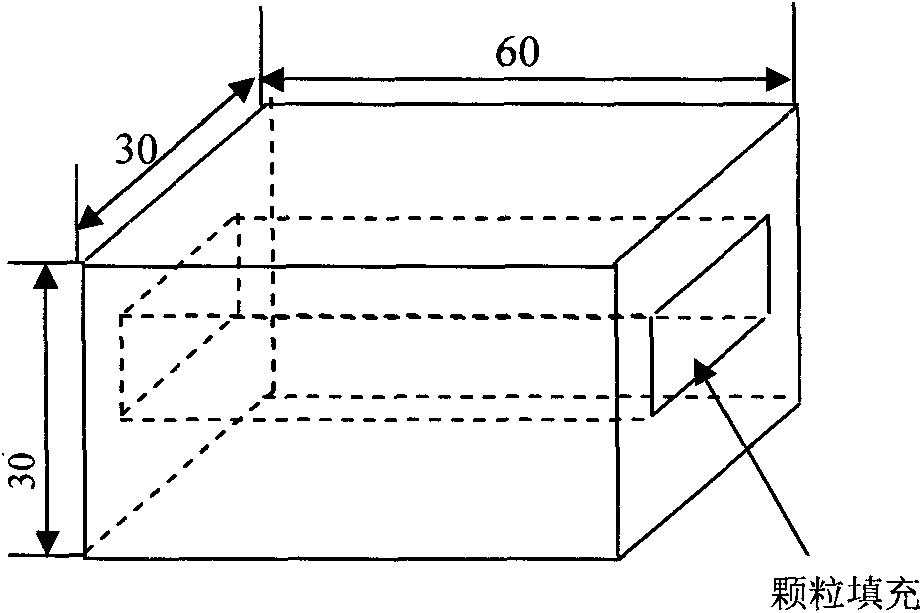

Examples

Embodiment

[0020] First, purchase 36-mesh SiC particles (green) for industrial use. In order to avoid the impact of trace impurities on the subsequent surface treatment effect, the SiC particles are first ultrasonically cleaned with acetone solution. The specific cleaning steps are:

[0021] (1) SiC particles are placed in a beaker;

[0022] (2) Add an appropriate amount of acetone solution into the beaker and put it into an ultrasonic cleaner for cleaning for 5 minutes;

[0023] (3) Rinse with distilled water;

[0024] (4) Blow dry with cold wind and store for later use.

[0025] Take appropriate amount of cleaned SiC particles for surface alloying treatment by calculation. The specific treatment method is: determine the addition amount of alloy powder (Al powder) and binder through coating test (see Table 1), and thus can be calculated respectively The surface is coated with 200 mesh Al powder and the amount of adhesive and weighed for future use.

[0026] Thoroughly mix the cleaned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com