Biological carbon modular composite vertical-flow artificial wetland system

A constructed wetland system and biochar technology, applied in sustainable biological treatment, biological water/sewage treatment, granular microbial carrier treatment, etc., to achieve the effects of preventing floating, promoting plant growth, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

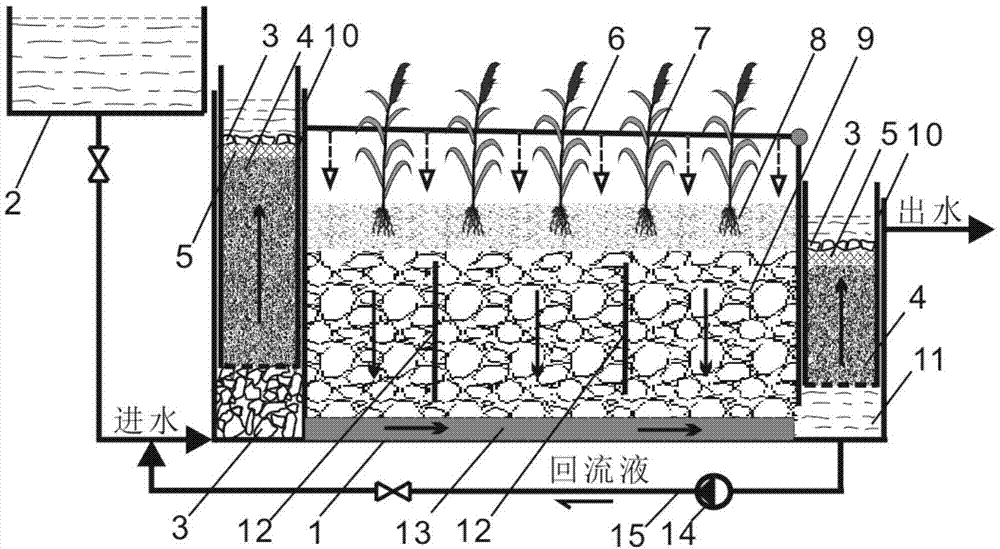

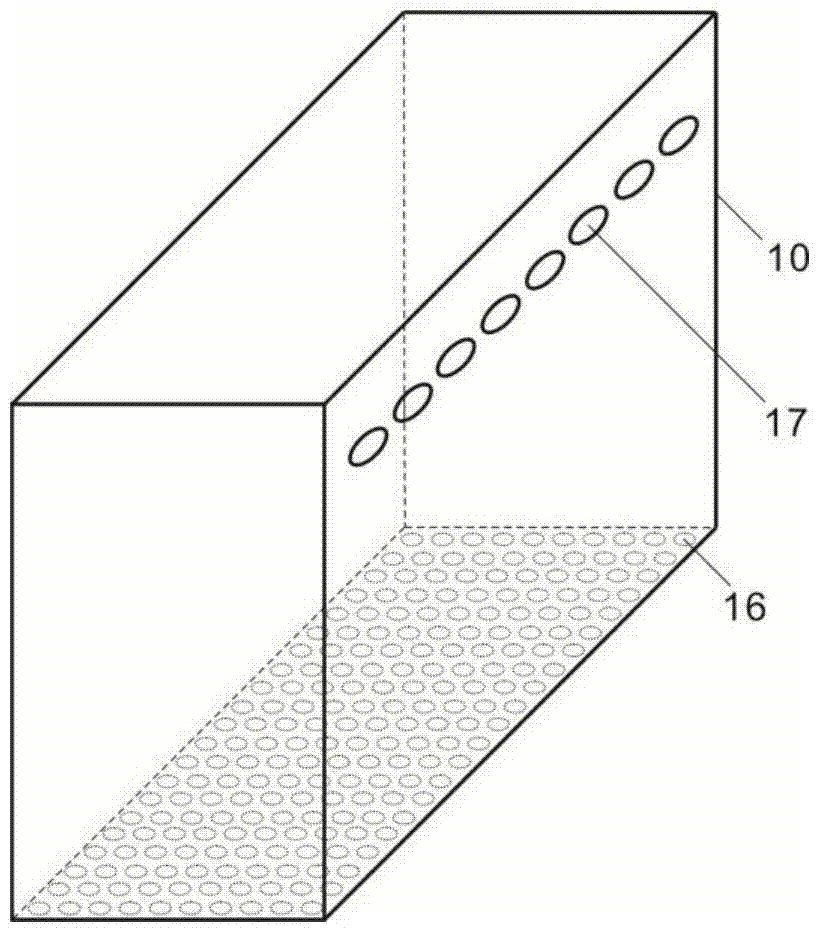

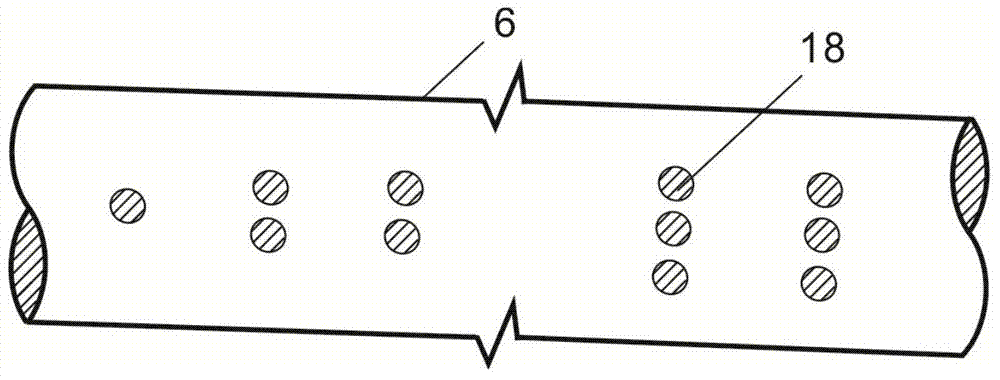

[0028] Such as figure 1 As shown, the bottom layer of the front end of the wetland bed 1 is a gravel layer 3, the gravel particle size is 10mm-20mm, and the thickness is 200mm. 600mm, on the biochar layer 4 is the filter material layer 5, the filter material is made of non-woven needle-punched felt, the uppermost layer is covered with a gravel layer 3, the gravel particle size is 10mm-20mm, and the thickness is 30mm; the middle and lower layer of the wetland bed body 1 is The gravel and biochar mixed filler layer 9, the gravel particle size is 10mm-30mm, the thickness is 450mm, the upper layer is the quartz sand and biochar mixed filler layer 8, the quartz sand particle size is 2mm-4mm, the thickness is 200mm, biochar is added The volume ratio is 10% to 30%. The quartz sand and biochar mixed filler layer 8 is planted with wetland plants 7. In this area, a water retaining plate 12 is set with a height of 250mm to 350mm. The distance between the bottom of the water retaining pla...

Embodiment 2

[0035] A biochar modular composite vertical flow artificial wetland system, including a wetland bed, a water inlet tank, a gravel layer, a modular biochar layer, a mixed packing layer, a filter layer, wetland plants, a return device and a water distribution pipe, and the water is fed in sequence After anoxic gravel layer and biochar layer, aerobic mixed packing layer, and anoxic biochar layer, a reflux device is installed inside; the biochar layer is modular, and the biochar layer is a filter material layer. Non-woven needle-punched felt is used, and the filter material layer is covered with a gravel layer; the water behind the biochar layer at the front enters the mixed sand layer and mixed gravel layer through the high-level distribution pipe in the form of falling flow, and the water in this area is downstream; Part of the sewage flows back to the water inlet, and the other part flows out through the back-end biochar layer; anti-seepage materials are added to the side wall and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com